The use of UAVs for commercial applications is booming and has a significant and positive impact on the cost of operations, downtime, and security for those who use it. We have regular contacts with our customers who tell us how they use Elios. They relate their interventions and the benefits generated by the deployment of Elios. Through this compilation of five stories, we want to share with you the impact that Elios had on their lives. This selection of stories shows the different forms that the benefit of commercially using drones indoor can take. We hope that they will give you an idea of how to use drones to accompany you in your industrial inspection tasks, or if you are already using drones to perform indoor inspection, to bring you new ideas and opportunities to grow your business.

#1 Taking radiations into consideration

When you save 50K per minute of flight and reduce human exposure to radiation.

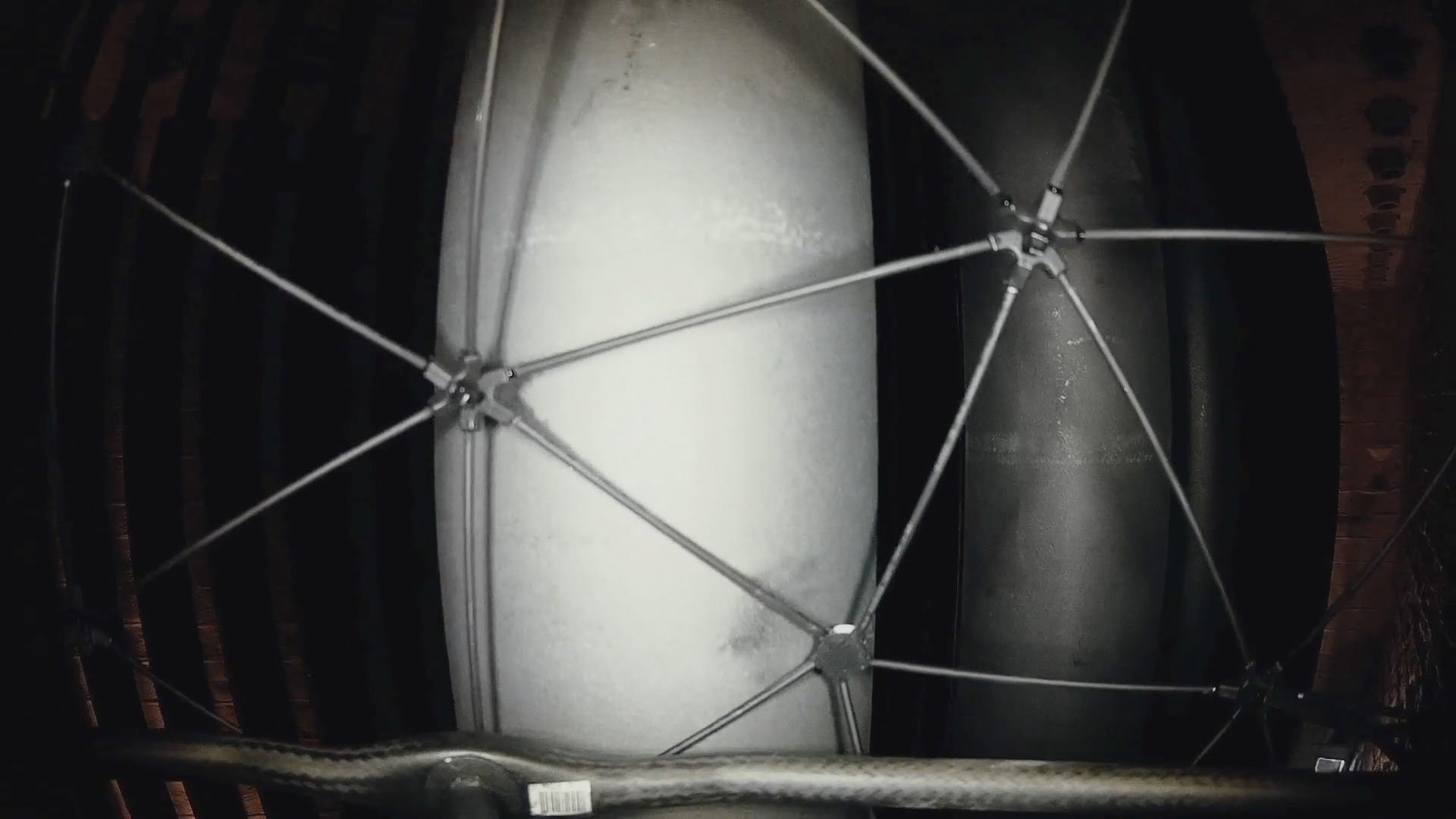

It was during May last year that we received the feedback from one of our customers, an ALARA planner for a nuclear power plant located in the eastern United States. During the discussion, we discovered how much impact Elios had on the power plant maintenance team a few weeks after the acquisition of two Elios earlier that year. This ALARA planner of 58 years old describes his job in the following ways: "Our job is to ensure that workers here are exposed to the minimum amount of radiation necessary to keep our plant running safely. We use a variety of techniques and tools to accomplish this, including mockups of high dose work, shielding components, prefabrication, and recently, robotics."

With his team, this ALARA planner undertook several straightforward missions. However, one of them held our attention. It consisted of visually checking if a modest pressure release valve of a boiler located in the basements of the reactor was leaking. Prima facie, controlling a valve situated a few meters of the ground at the top of a ladder seems within reach of every average person. Only here, this valve is in a highly radioactive area, which involves the implementation of a series of security measures to allow someone to scale up to the top of the boiler and control it.

These safety measures imply reducing the plant's production power to 20% of its capacity. This operation takes 6 hours and allows to limit the radiation dose received by the two individuals entering the dangerous area to check the valve. To the extent that the control is satisfactory, then a new 6-hour cycle is necessary to bring the plant back to its maximum production capacity. This entire procedure of lowering the power of the plant to make the inspection possible engenders a loss of revenue of half a million US dollars. Moreover, despite the power reduction to 20%, the visual inspection operation exposes the two inspectors to a dose of 250 millirems. This dose represents one-tenth of the annual authorized/recommended limit for a human.

It goes without saying that the impact of using Elios for these employees of a major Power Generation player in the US is substantial. By using Elios, the need to reduce the power of the plant becomes obsolete and the exposure to radiations nonexistent. The comfort of inspection also increases because Elios does not have a limited exposure time to radiation, the only constraint being its limited flight time that forces the pilot to bring it back to him every 10 minutes to change the battery. This discussion allowed us to understand the impact of indoor drones on the daily life of radiation specialists and maintenance team in the nuclear industry. This story, apparently, affected a large number of power generation players in the United States because, today, a third of US nuclear power plants are equipped with an Elios, and this figure continues to grow.

#2 Burners wasted

When unplanned inspection saves you more than 7M USD.

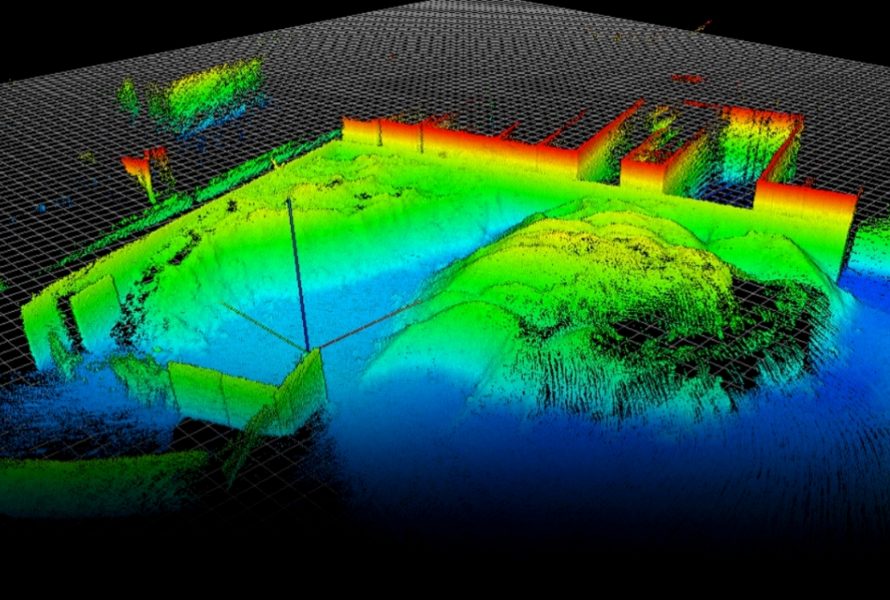

Last October, our colleague Johan went to visit one of our clients based in Argentina. This client, in charge of the operations of one of the largest power plants in the country, asked Johan to demonstrate Elios' capabilities directly at his site, during an inspection mission. Johan was requested to inspect the burners of several boilers, formerly coal-fired, and recently converted to fuel and gas. For the first boiler, the burners had been changed a little less than two years before the inspection, and the burner warranty was approaching its expiration date. It was therefore planned to inspect them. And it was about time! Some of the burners were in a critical condition.

It took Johan only one hour from the deployment of Elios to the visualization of the footages on the PC. This efficiency impressed the customer who concluded that there was still enough time to inspect the burners of the second boiler, something that they did not initially plan because the burners were less than a year old. That's when Elios made its biggest impact. The burners were in a condition that was unquestionably not normal nor anticipated. In this condition, it would have been potentially dangerous to restart the boiler with the risk of extending the damage beyond the burners.

As a result of the inspection, the operation team did not restart the two boilers. Thanks to aerial photographies shot with Elios, however, the customer had a visual proof allowing him to claim the change of the burners under warranty. With a cost of around $300K per burner and 24 burners to replace per boiler, our customer was delighted by his first experience with Elios. Beyond the savings achieved by inspecting the burners of its boilers on time, our client has estimated that using Elios instead of traditional means had saved him 30'000 USD in addition to 3 days of shutdown per boiler. Following this inspection, our Argentinian customer has acquired an Elios and a Range Extender to improve the inspection quality and frequency of its boilers.

#3 Tragic incident

When a tragic incident leads you to innovate.

"Our thoughts go to the victims of the incident that gave rise to these few lines."

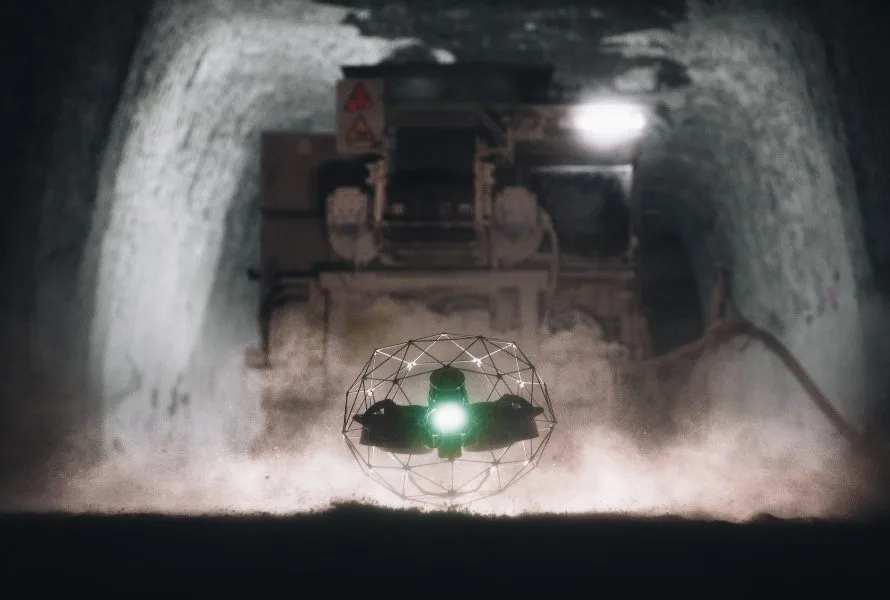

This tragic story portrays a reality that is, unfortunately, still taking place too often during confined spaces inspections or while working at height. In the United States alone, the year 2017 ended with 162 people dead after falling from a platform in height at their workplace (see OSHA numbers). Not all these accidents have happened in confined spaces, but the peculiarity of working in confined space, beyond being responsible for many asphyxia, is that it increases the difficulty of setting up means of access (when working at height) and especially the difficulty of rescuing victims of an accident.

After the collapse of a scaffold erected on the occasion of the inspection of a boiler superheater, causing the death of five workers, the maintenance team in charge of the said boiler had decided to call on one of our clients to find a safer alternative to inspect the superheater. This early adopter of Elios saw in this project the opportunity to apply Elios and was commissioned to gather footages of the tubing hanging at 70 meters of the ground. By trusting the potential of technological innovation, the owner of the boiler had found a way to reinforce its preventive measures to reduce the risk associated with working in confined spaces.

As part of this mission, the entry into the boiler was necessary, but the erection of scaffolding wasn't. Thanks to Elios and the pilot dispatched for this test mission, the inspector in charge of the visual inspection was able to check the integrity of all the tubing as well as the level of deterioration of the superheater fasteners right from the ground.

For the maintenance team on site, the impact of Elios has gone beyond financial aspect since it allows them to limit the risks associated with working in confined spaces. When a visual inspection reveals defects that require the intervention of workers, the images provided by Elios allow to plan, knowingly, the operation of setting up scaffolding and to limiting its erection to the areas requiring access. This approach, known as tactical scaffolding, reduces considerably the time spent and the risks taken into confined space, but more about it a little further.

#4 Thumbnail size notch on a pipe

When commissioning an asset takes an unexpected turn.

A little before the summer of 2017, it is a refinery builder who has experienced the benefits of indoor inspection by drone. It was towards the end of a furnace assembly that the event occurred. An inch-sized impact was found on one of the pipes in the furnace, which cast doubt on the quality of the other pipes already installed by the building contractor. The effect of such a control, within a few weeks of the commissioning of the refinery, involved a delay in delivery because traditional inspection methods require the installation of scaffolding in an excessively restricted space with the risk of damaging the pipes in place.

Indeed, these pipes, made of a special alloy, are vulnerable to the slightest impact with another metal. As a consequence, the scaffolding needs to be powder-coated before being installed in the cramped space. This inspection, which involved 4 weeks of delay, was reduced to one week thanks to the intervention of one of our client who uses Elios to provide confined inspection services. Thanks to the meticulous use of Elios and organization of the inspection team, each pipe of the furnace could be inspected without causing any damage to the pipes and making a critical situation even more critical. The turn that this commissioning took was unexpected and could have been catastrophic, but thanks to Elios and the piloting experience of our customers, this catastrophe has been avoided.

#5 Tactical scaffolding

When knowing before acting saves you up to 70% of scaffolding.

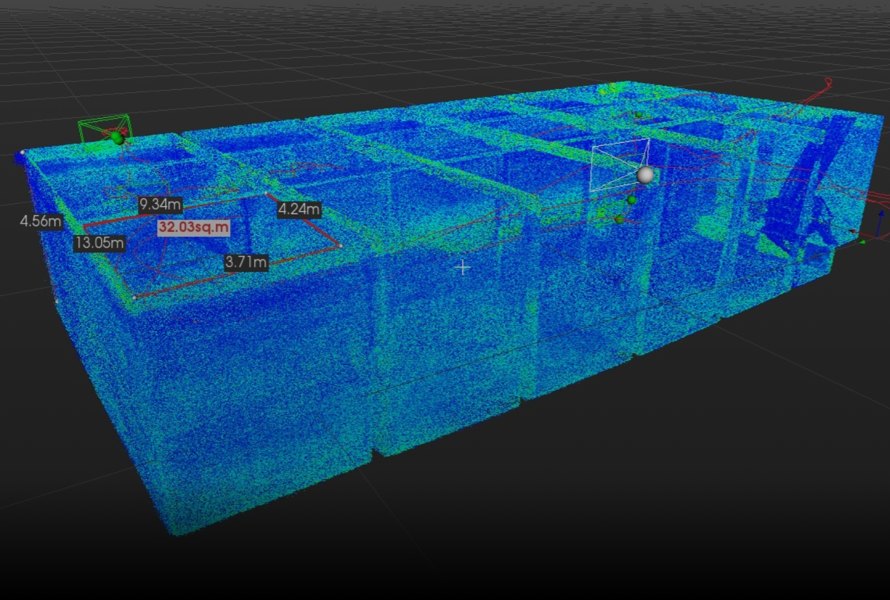

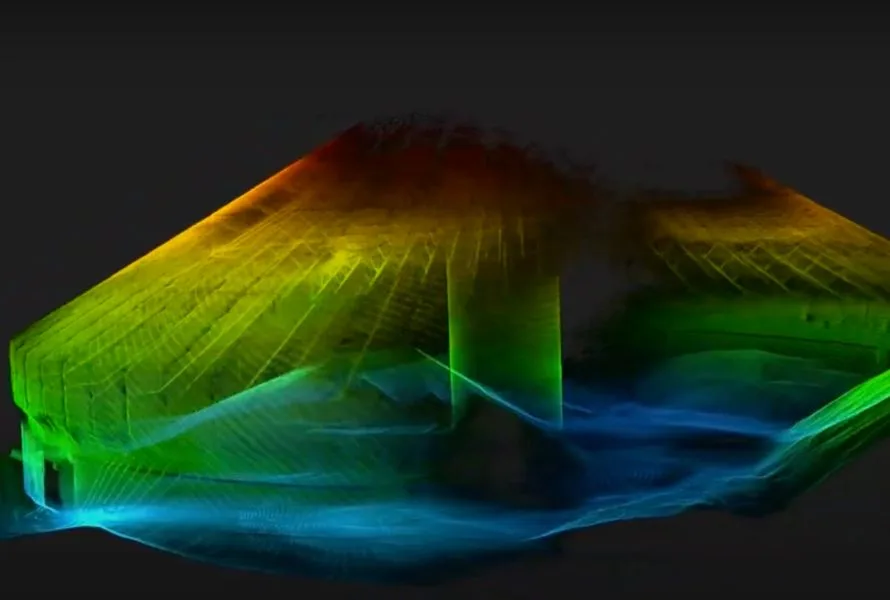

The company Inspectios, based in Poland, is specialized in the drone-based inspection of confined spaces in several heavy industries. Notably, the inspection of boilers with Elios has no more secret for them and, thanks to that expertise, they have signed a recurring visual inspection contract for a specific boiler. This boiler is capable of delivering more than 460 MWe and operates under supercritical parameters. This mode of use, however, requires scheduling a maintenance operation every three months.

Before commissioning Inspectios, the owner of the boiler was forced to stop it for periods lasting up to 22 days to allow scaffolding to be erected all the way through the boiler, into the combustion chamber, and in separators. During this planned shutdowns, the time allotted for the inspection and repair amounted only to a week, and the loss of production engendered by the assembling and dismantling of the scaffold amounted to 2M EUR. To this number had to be added the price of the scaffolding itself, which amounts to 200K EUR. During each inspection, defects were found here and there in the boiler, but each time the maintenance team had to conclude that a large part of the scaffolding had been erected unnecessarily.

Since recently, each planned shutdown is preceded by the intervention of Inspectios who flies Elios to perform a visual inspection of the boiler. With this procedure, the maintenance cost of the boiler has considerably reduced. Indeed, the visual inspection with Elios only takes Inspectios two days, thus allowing the team in charge of the maintenance to proceed only with the erection of the required scaffolding and save precious days of downtime. During the various inspections carried out by Inspectios, the effective scaffolding requirement appeared to be only 30% of the total area, on average. The savings associated with not having to erect 70% of the scaffolding represent a substantial 1.4M EUR of additional revenue. In this case, the impact of Elios on the finances of the owner of the boiler is significant. Likewise, it impacts Inspectios' finances who has been awarded a recurring inspection contract for having the audacity to bet on and push for new and innovative technology.