What Is Industrial Radiography Used For?

In the medical field, radiography is used to create images that reveal the condition inside the human body—so, images of things like bones, tissue, or internal organs.

In industrial settings, radiography is used to help inspectors detect flaws that might not be visible to the naked eye.

In this guide we’re going to look closely at what industrial radiography is used for across various industry to support work in inspections. If you’re looking for information on how radiography is used in medical settings, we recommend reading this article by the FDA.

[Industrial radiography is just one of the non-destructive testing (NDT) methods that inspectors use. Learn more about NDT in this in-depth guide.]

[Note: Industrial radiography is also sometimes called industrial radiology.]

Here is a menu to help you find the information you’re looking for:

- Industrial Radiography

- Radiographic Testing—How Does It Work?

- Industrial Radiography Equipment

- Industrial radiography Careers and Salary

- Drones and Industrial Radiography

Radiographic testing used on a pipe

Industrial Radiography

Industrial radiography (IR) is the use of radiation to inspect the integrity and structure of a material.

Both gamma rays and x-rays are used in industrial radiography. These two types of radiation can travel through many substances, allowing inspectors to conduct internal examinations for quality without having to do anything to the thing being examined.

Industrial radiography has two primary uses:

- Manufacturers use industrial radiography to look for defects inside materials they use.

- Inspectors use industrial radiography to look for defects in industrial assets, in order to ensure they are safe to use and comply with mandated inspection requirements.

Common industries that use radiography in manufacturing include automakers and airplane makers, who use radiographic testing to examine vehicle parts and plane parts.

[Related read: What Is a Dosimeter and Why Is It Important?]

Common industries that use radiography in inspections include any operation that uses boilers, welding, or pipes, including Oil and Gas and Power Generation.

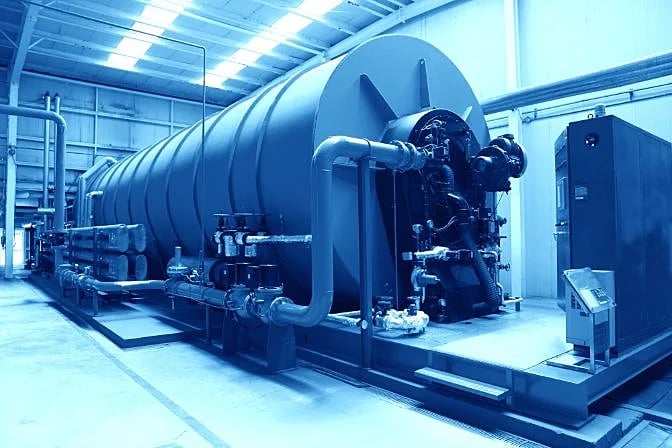

An industrial boiler

Non-Destructive vs. Destructive Testing

As a side note, inspection methods like radiography that allow inspectors to examine a material without changing it are called non-destructive testing methods for that very reason—they don’t change or “destroy” the thing being tested.

In contrast to NDT methods, there are testing methods that require taking a sample of a substance or altering it in order to learn more about it.

For example, if you want to find out whether there is lead in the paint used in a building, one easy method is to apply a chemical mix that will change colors when it encounters lead. This testing method permanently alters the paint, and would therefore be considered a destructive testing method.

A Note on Safety in Industrial Radiography

The radiation used in industrial radiography comes from a radiation-producing machine or a radioactive materials source.

Industrial radiography can be a powerful method to determine the interior structure of a material, but it can also expose people to harm if it’s not done properly.

Compared to other types of work with radiation, industrial radiographers experience the most accidents that involve radiation.

Given these dangers, strict processes are in place and required by law for industrial radiography. See the Careers and Salary section below to learn more.

Radiographic Testing—How Does It Work?

Radiographic testing is the act of using radiation to test or inspect a material for inspection purposes.

Radiographic testing like this:

- Line up radiation. An inspector points radiation (gamma rays or x-rays) at the object they want to inspect.

- Line up detector. On the other side of the object, the inspector places a detector in line with the beam of radiation.

- Take recordings. The detector takes recordings on the radiation passing through the object.

- Analyze recordings. These recordings are then analyzed to determine the findings from the test.

As you can see, the benefit here is all in the analysis.

At a high level, what industrial radiographers look for when analyzing findings from the detector are places where less or more radiation was able to pass through the object.

Less radiation passing through means that the material is thick in those places, indicating that it’s probably in good working order. More radiation passing through, on the other hand, could indicate that there is a crack or flaw in that area, causing the material to be thinner and thus allowing more radiation through.

The pictures produced from radiographic testing are called radiographs. These days, most cameras used for radiography record digital images, but they used to be recorded using film.Industrial Radiography Equipment

The two primary types of industrial radiography equipment use the two different types of radiation we’ve already discussed—x-rays and gamma rays.

Gamma Rays Industrial Uses & Equipment

Industrial radiography equipment that uses gamma rays leverages radiation that comes from radioactive material contained within the equipment. This type of equipment is smaller than equipment that uses x-rays, making it useful inside smaller spaces.

industrial gamma radiography equipment doesn’t require electricity, but that also means it can’t be turned off.

The device will always be emitting some amount of radiation, and the only way to protect workers from this radiation is to enclose it inside a metal cover made for this purpose.

X-Rays Industrial Uses & Equipment

Industrial radiography equipment that uses x-rays is typically larger, so it’s better suited to radiographic testing inside large spaces, such as those found in factories or warehouses.

industrial xray radiography equipment runs on electricity, and can be turned on and off, which means that it is safe to be around when it’s off (i.e., no protective shield is required for these devices).

Given the potential dangers of radiation, the use, ownership, and transportation of radiography equipment requires a license in the U.S., and in several other parts of the world.

In the U.S., rules on licensing requirements are created and overseen by the U.S. Nuclear Regulatory Commission. Learn more here.

Industrial Radiographer Salary and Careers

Want to be an industrial radiographer?

Here’s what you need to work in the radiography industry:

- A high school diploma

- A certificate from an industrial radiographer training program

what is an industrial radiographer?

An industrial radiographer uses radiation to conduct tests on materials, equipment, and assets in order to determine whether they are sound or have any flaws present.

For asset inspections, industrial radiographers typically inspect large pieces of equipment like aboveground and underground pipelines, such as those used in the Oil and Gas industry, or other large machinery.

Radiographic testing used on a weld in an aboveground pipe

To do the work, industrial radiographers create images using x-rays and then examine those images, looking for defects or flaws.

While doing this work you’ll have to make sure you’re following the right safety protocols required to avoid or reduce exposure to radiation.

Jobs in industrial radiography are typically full-time.

Those who do this work have to travel to job sites, since the objects being tested using radiography are usually large, stationary assets that must be inspected on-site.

What Does an Industrial Radiographer Salary Look Like?

According to ZipRecruiter, the national average industrial radiographer salary is about $54,000 a year.

Here are salaries from the top-paying industrial radiography jobs in the U.S.:

Data provided by ZipRecruiter

As you’ll notice, your salary may vary depending on your location.

Keep in mind that inspectors might be able to make more—and in some cases, a lot more—by obtaining other types of certifications and experience that allows them to do additional types of inspection work.

Industrial Radiography Certification

In the U.S. and in many other parts of the world, you must become certified to do industrial radiography work.

Certification requirements vary from one state to another in the U.S. and elsewhere, but they generally require:

- Hands-on training for a specified number of hours with a certified industrial radiographer

- Completion of a radiation safety course

- Completion of a written exam

Some of the most common types of certification include:

- RAM. Certification just for radioactive materials.

- X-RAY. Certification just for x-ray machines.

- Both. Certification for both radioactive Materials and x-ray machines.

In the U.S., several states have their own nationally recognized IR certification programs. Learn more here.

As technology improves, it’s likely that we’ll be able to create full, highly detailed 3D models of the interiors of assets. These models can serve as a visual record for monitoring corrosion in an asset, just as high quality still images and videos currently do.

Drones and Industrial Radiography

Drones are not commonly used in industrial radiography right now, but that could change over the next few years.

That being said, there is at least one drone made by a company called Pacific Imaging that is equipped with an x-ray imaging machine.

The drone is called DroneX and it is being used to inspect conductor sleeves on power lines.

Photo credit: Pacific Imaging

Based on our research, the DroneX platform is already in use for power line inspections, allowing inspectors to collect data about the condition of power lines without having to endanger themselves by climbing or standing in a bucket truck to conduct a manual inspection.

As drone technology continues to improve, we may see more and more drones equipped with x-ray imaging, pushing the boundaries of how industrial radiation can be performed.

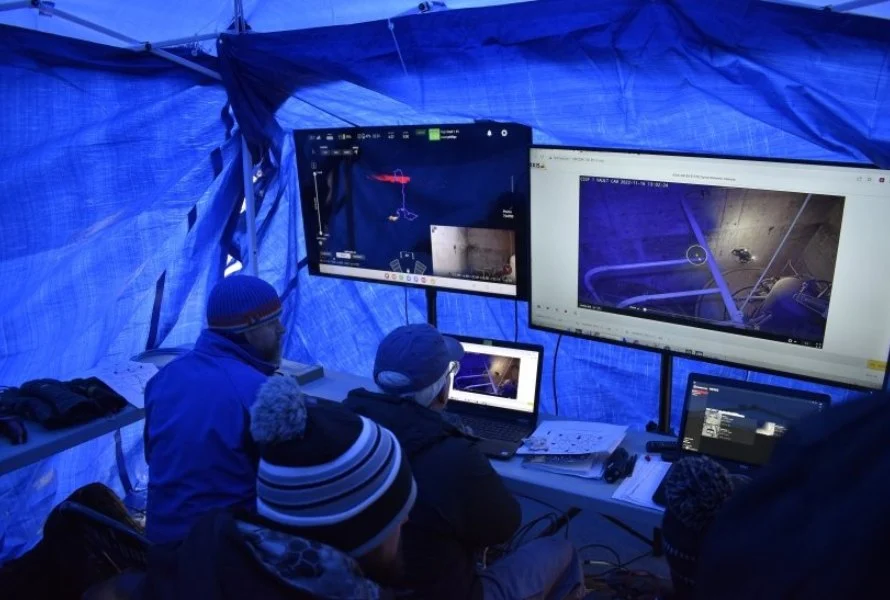

We are hosting demonstrations throughout the world to showcase our new indoor inspection drone.

Sign up to see the Elios 3 live in a location near you.