INDUSTRIA 4.0

Prepárese para un mundo nuevo de inspecciónes y mapeo de interiores

Las inspecciones realizadas con los drones no son solo tecnología del futuro, son ya una necesidad en un mundo en continuo cambio digital. Inmersos en la Cuarta Revolución Industrial, toda organización busca la transformación digital de sus procesos operacionales sin olvidar ni su rentabilidad y ni la mejora del entorno de trabajo.

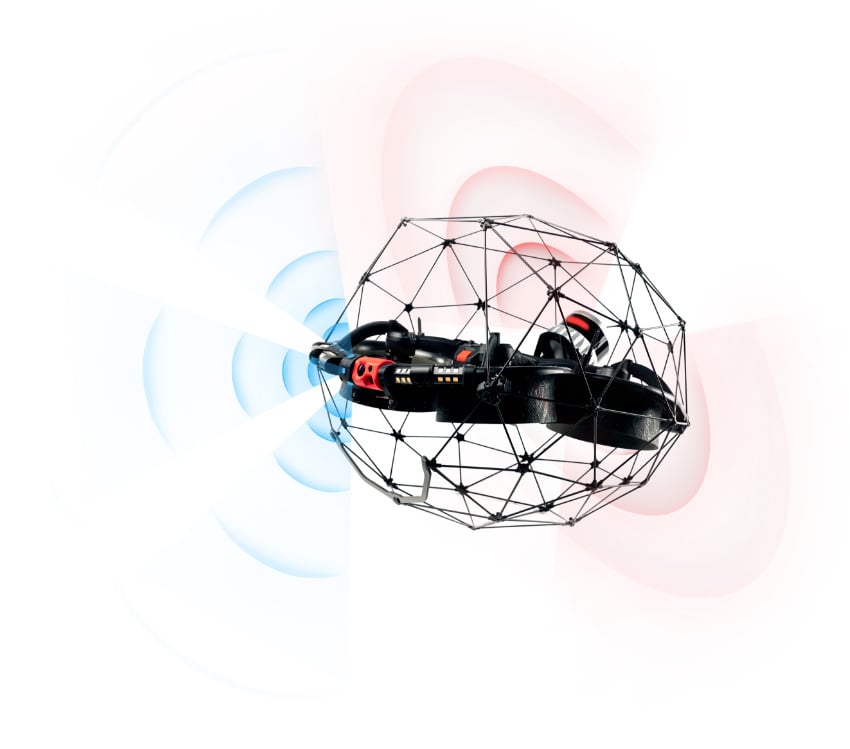

Elios 3 ayuda al sector industrial a conseguir sus objetivos llevando sus inspecciones y mapeos un paso más adelante.

Mucho más que una cámara voladora, Elios 3 es una poderosa herramienta de recolección de datos.

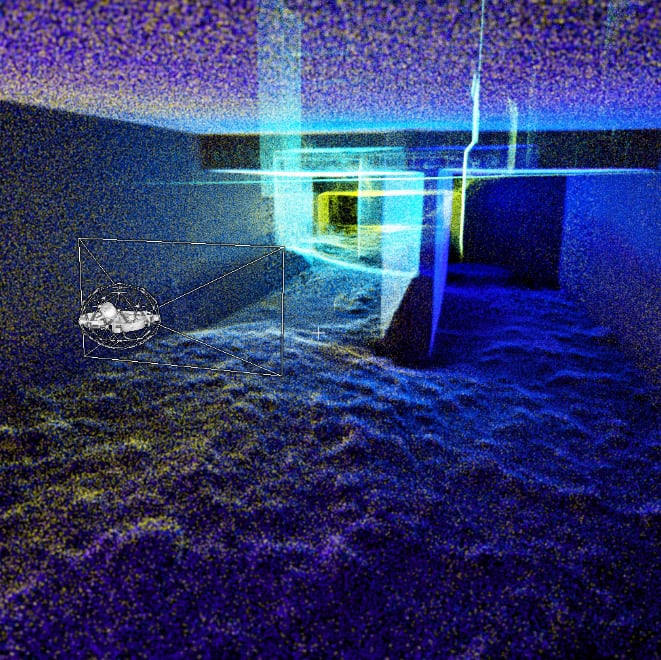

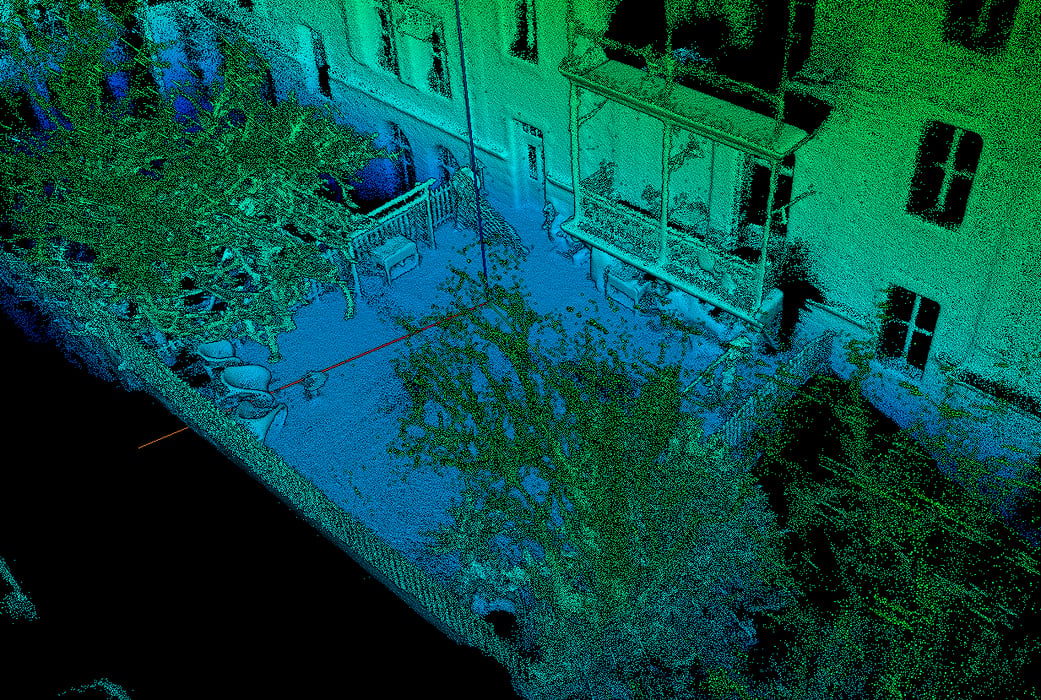

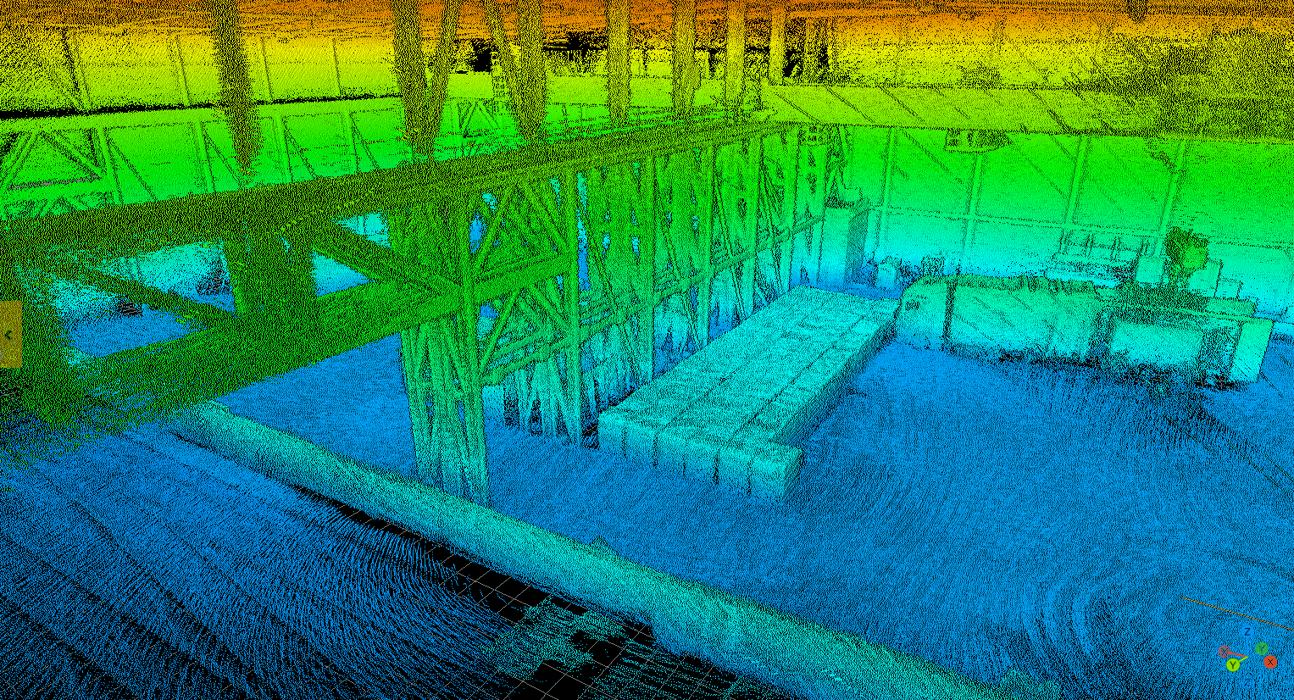

Confiando en el poder de la visión por computadora y el mapeo LiDAR, Elios 3 es un dron interior versátil que abre las puertas a un mundo donde realizar inspecciones sistemáticas no requiere meses de capacitación, la elaboración de informes se hace de manera intuitiva en un modelo 3D de tu activo, y la conciencia situacional está integrada en la aplicación de pilotaje.

No es solo una cámara que trabaja en el aire, el Elios 3 es una inigualable herramienta de extracción de datos.

Gracias a su potente visualización digital y al mapeo LiDAR, Elios 3 se convierte en un dron para interiores que facilita la entrada a un mundo donde no es necesario formarse intensivamente para realizar inspecciones sistemáticas y donde la transmisión de informes se realiza de forma intuitiva con modelos en 3D de cualquier zona de la instalación, mientras la aplicación de pilotaje controla la ubicación con suma precisión.

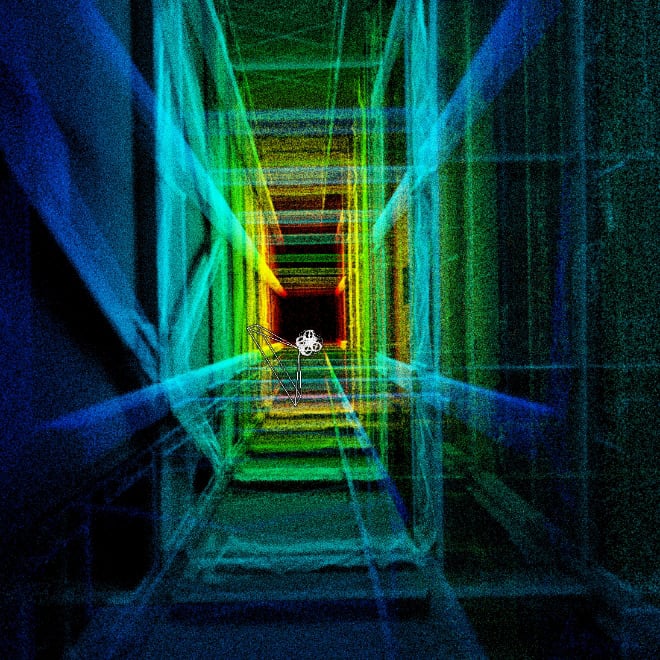

Motor SLAM con FlyAware™

Diseñado por FlyAware™

FlyAware™ representa la combinación perfecta de visualización digital, tecnología LiDAR e la tarjeta gráfica NVidia. Igual que un GPS con calibración milimétrica en interiores, el dron es capaz de generar mapas instantáneos en 3D que le permiten detectar al momento, cualquier zona circundante. En la actualidad, FlyAwareTM facilita una estabilidad sin igual que se acompaña de un control de ubicación altamente preciso. Cuya autonomía completa logrará ser prometedora para inspecciones autónomas en espacios complejos confinados.

Estabilización gracias a SLAM

Una estabilidad inquebrantable y firme. Bajo cualquier situación.

El algoritmo de la innovadora estabilización con SLAM es capaz de captar hasta el movimiento más imprevisto e imperceptible del dron y, simplemente, ordena su corrección inmediata al controlador de vuelo. Algo así hace que el dron fluya en el aire casi como si no se moviera, incluso bajo las condiciones más inestables. Con el Elios 3, cualquier piloto de drones, con cualquier experiencia de manejo, logrará realizar las misiones más difíciles sin apenas formación adicional.

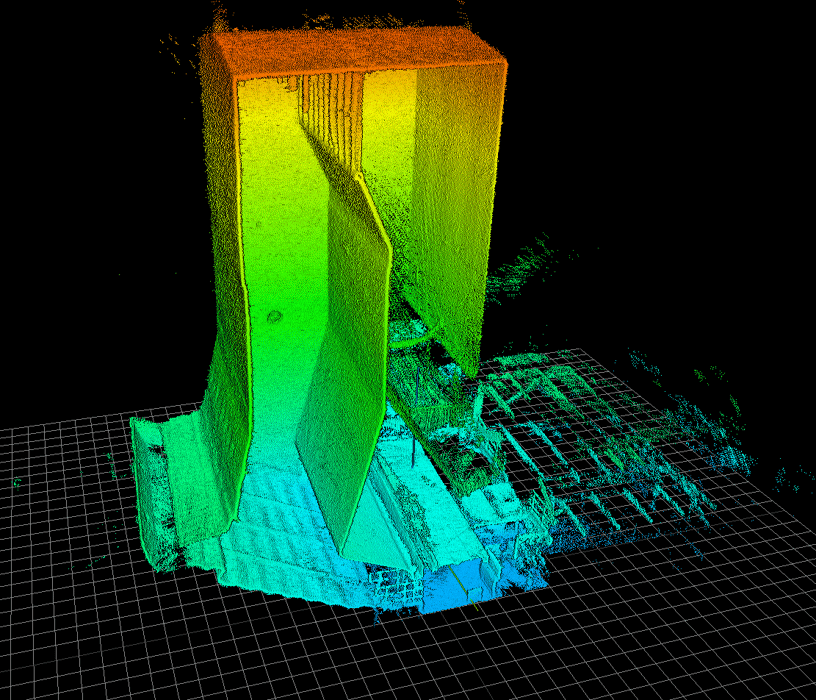

Mapeo 3D en tiempo real

Control de ubicación sin error alguno.

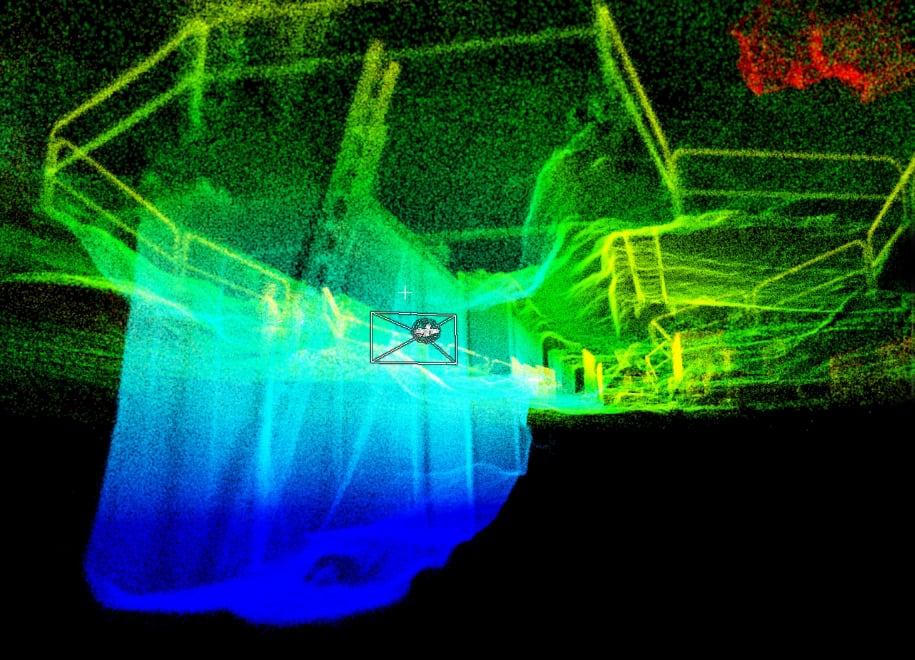

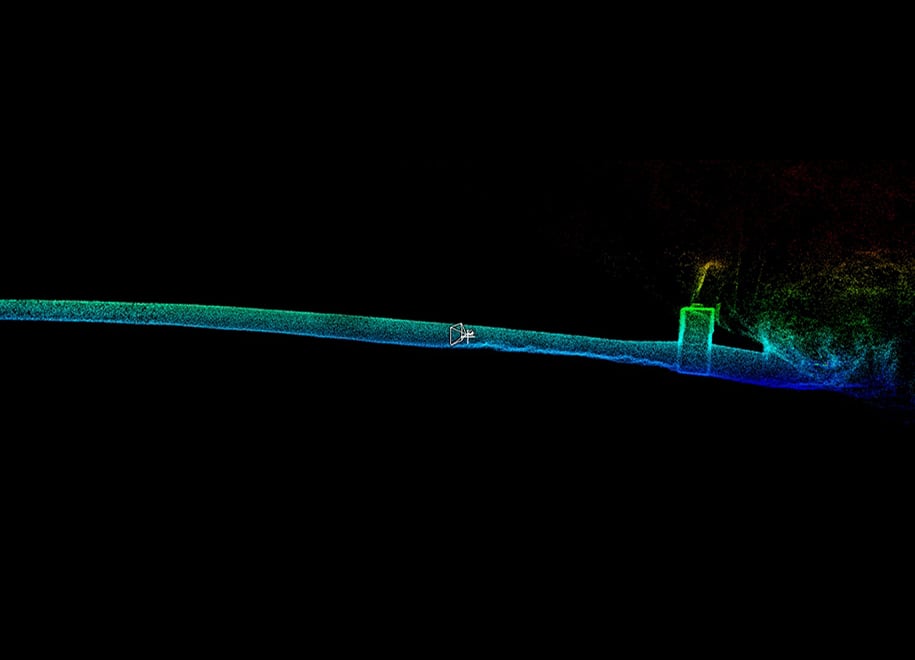

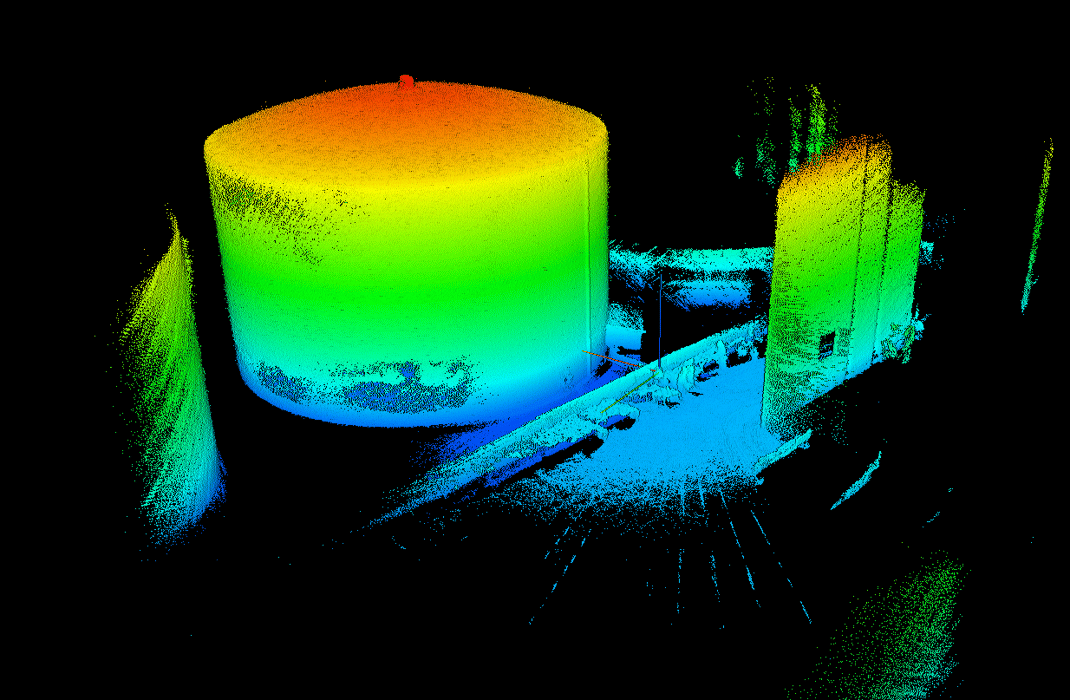

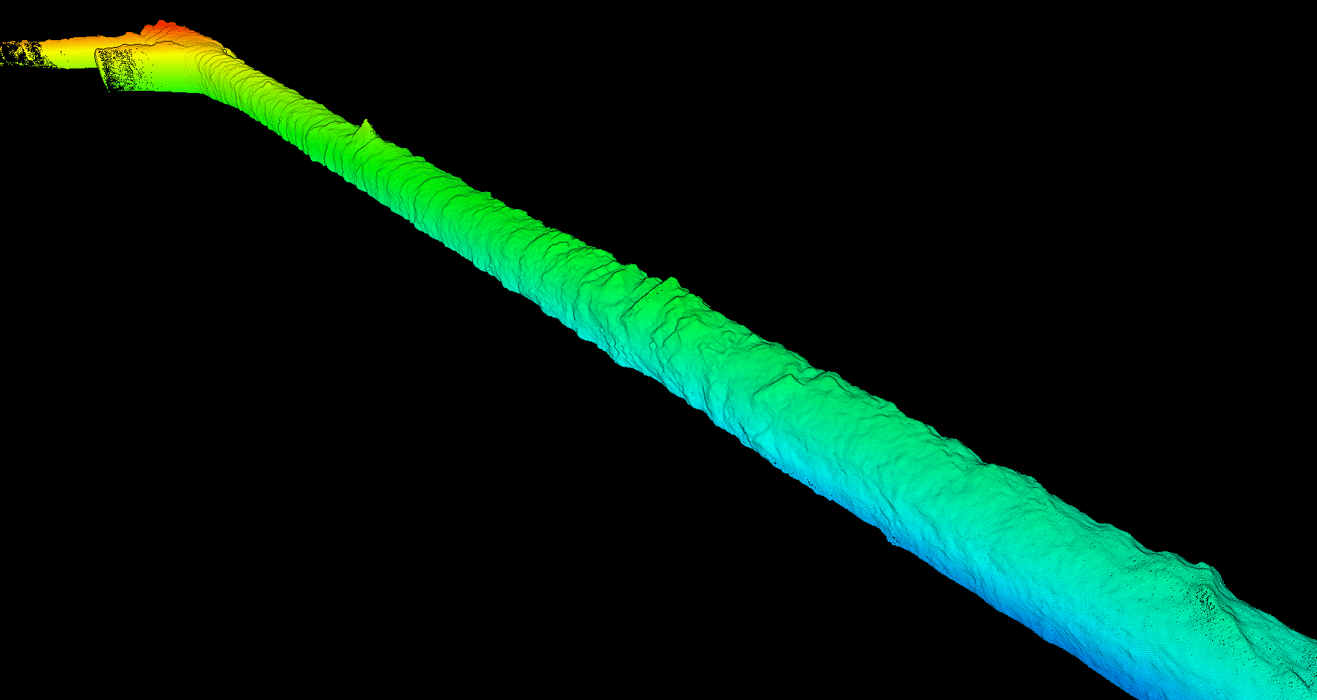

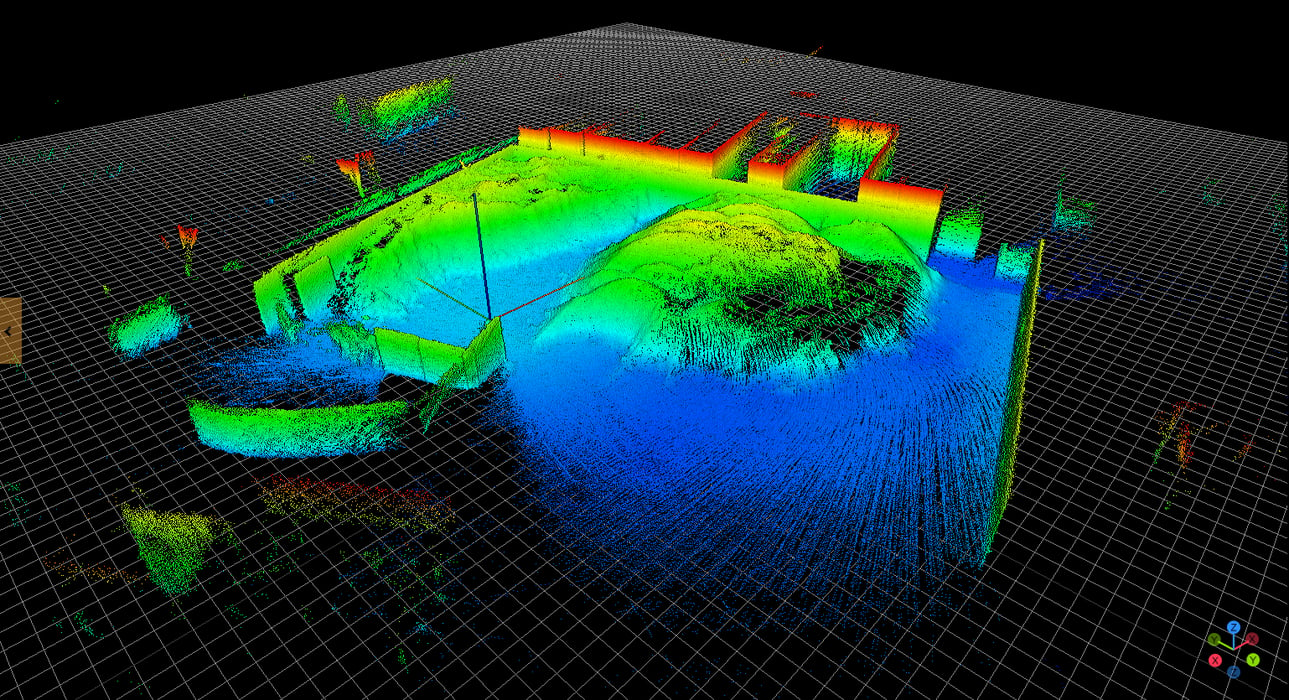

Su tecnología LiDAR integrada realiza barridos continuos de las zonas circundantes para procesar un mapa con nube de puntos detallado al extremo. Este mapa se muestra instantáneamente en la aplicación Cockpit, haciendo que los pilotos conozcan la ubicación con total exactitud. Gracias a su vista 3D en tiempo real, sobre la trayectoria del dron y su entorno, se logran datos esenciales.

Una ubicación siempre precisa, sin lugar a dudas.

Sabemos dónde está el dron en todo momento. Así, el piloto puede elegir la mejor ruta de regreso para este dispositivo.

Una evaluación del alcance de la inspección.

Los datos de mapeo acumulados muestran una visualización absoluta de la mapa para poder analizar el alcance de la inspección en cualquier momento.

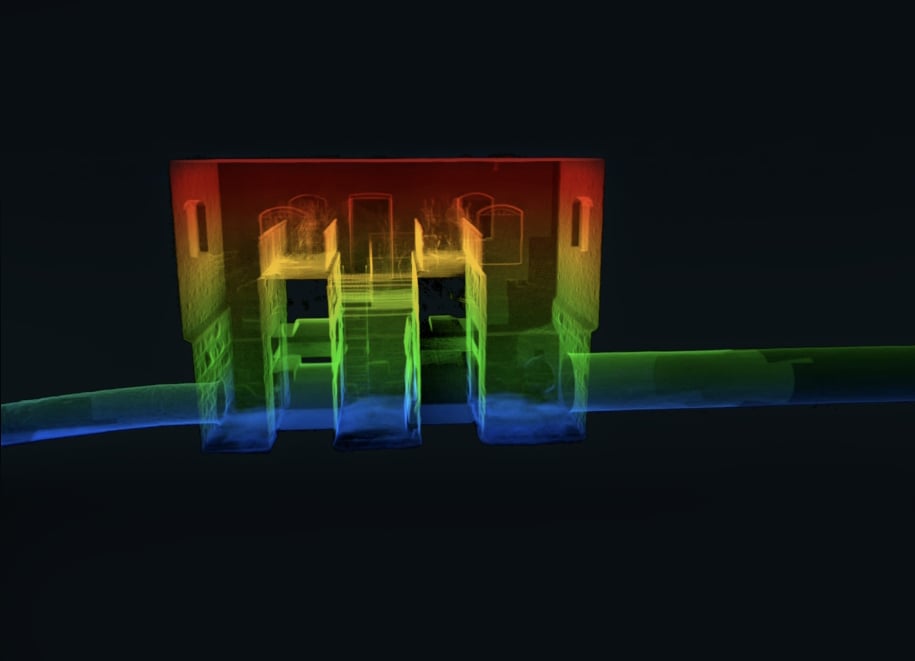

Transmisión de informes 3D

Para saber en qué trabajo de supervisión y mantenimiento centrarse.

Desde la captura de datos hasta la toma de decisiones, los drones Inspector 4.0 y Elios 3 colaboran mutuamente para lograr su continuidad operativa e impulsar su eficiencia mediante todos y cada uno de los pasos del proceso de inspección.

Su solución para prospecciones en 3D

Nubes de puntos de calidad profesional.

Gracias a su integración con la versión de software de GeoSLAM, los datos de la tecnología LiDAR de el Elios 3 pueden procesarse para crear modelos 3D de inspecciones profesionales que faciliten a sus topógrafos el mapeo de las más ocultas e inaccesibles instalaciones interiores.

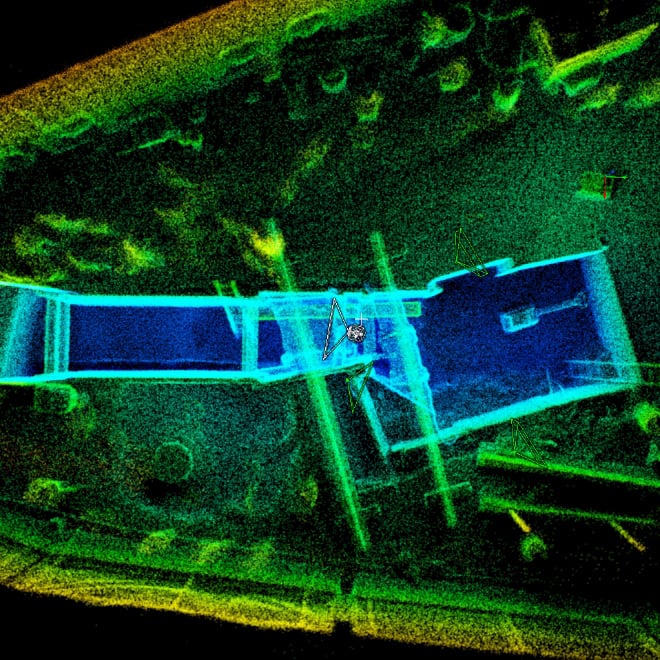

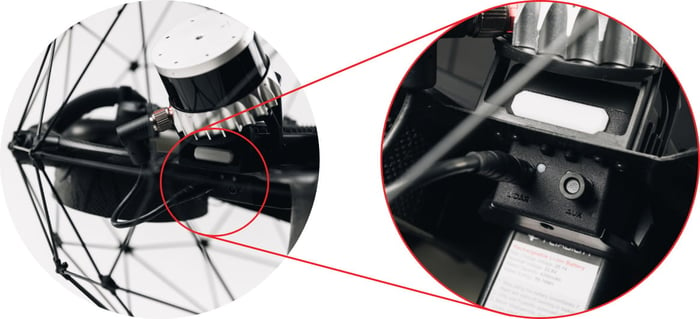

Bahía modular para carga útil

Una herramienta para inspecciones versátil y siempre actualizada.

La bahía modular de carga útil presenta dos puertos. Uno destinado a la tecnología LiDAR y el otro para cargas útiles de reserva. Su diseño exclusivo integrado facilita que sus funcionalidades de vuelo sean compatibles con múltiples aplicaciones futuras para interiores. Este convierte al Elios 3 en un dispositivo versátil y siempre actual, configurado para cualquier tipo de misión.

Available Payloads

Regreso-a-la-Señal

Mayor seguridad en el vuelo

Elios 3 monitorea automáticamente la conexión de video en vivo. Cuando la transmisión de video se interrumpe, el dron muestra un aviso en Cockpit, ofreciendo regresar de manera autónoma por su trayectoria original hasta que se restablezca la conexión de video.

La función Regreso a la Señal proporciona tranquilidad al piloto para explorar más lejos, incluso en condiciones de señal de radio marginal.

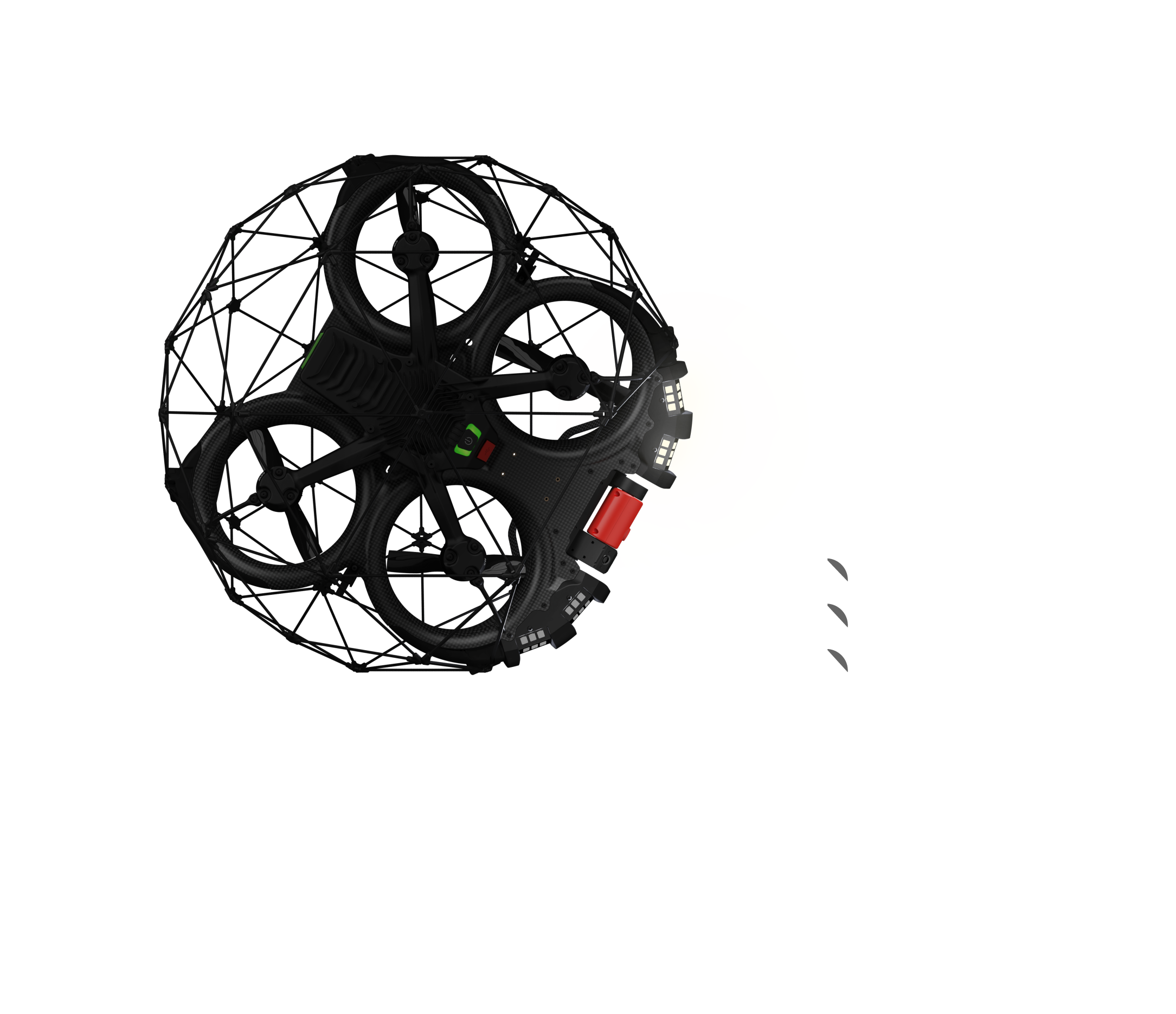

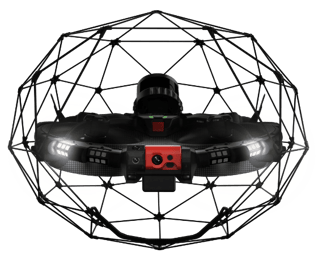

Un diseño robusto resistente a las colisiones

Perfecto para las tareas más complejas.

Diseñado a partir del controlador de vuelo resistente a colisiones pendiente de patente de Flyabilty, Elios 3 es apto para su uso en los entornos industriales más complejos. Gracias a su emblemática jaula y exclusivos motores de inversión, Elios 3 es el único dron del mercado capaz de estabilizarse en su posición y sin ningún impacto tras realizar un “looping” completo. Su sólido diseño IP-44 permite una inspección y mapeo bajo las condiciones más extremas sin tener que preocuparse de salpicaduras de agua o nubes de polvo.

*El Elios 3 no tiene certificación IP-44, pero ha sido desarrollado para cumplir con esta clasificación conforme al código de protección contra la penetración de materiales.

Inspecciones en detalle de la Carga útil específica

Mejorar la calidad de los datos.

La carga útil estática cuenta ahora con un campo de visión de 180°, libre totalmente de obstáculos, y con una cámara 4K, una cámara térmica y un sensor de distancia. El sistema de iluminación se ha rediseñado desde cero para transportarnos a una experiencia lumínica integral lo más impactante posible. Gracias a su sistema de iluminación antipolvo y oblicuo líder del sector, buscar en minas, pozos y grietas, o acumulaciones rocosas, se vuelve tan natural como si llevara una linterna en su mano. La carga útil de la inspección al detalle del Elios 3 proporciona una calidad de imagen excepcional, con una consistencia uniforme, incluso en la oscuridad.

Iluminación ingeniosa

Iluminación Oblicua

Detectar picaduras, grietas o acumulaciones.

Iluminación de 16K Lumen a prueba de polvo

Atraviese lugares sucios sin perder de vista su objetivo

Más tiempo de vuelo

Todo en una sola operación.

El Elios 3 ofrece hasta 12.5 minutos de vuelo* para llegar incluso más adentro con un solo vuelo. Gracias al mecanismo para su batería con acople y cierre, no tendrá ningún problema al manejarla.

*Tiempo de vuelo sin carga útil montada en la bahía de carga útil.