- Blog >

- How Indoor Drones at Nuclear Sites Reduce Radiation Exposure

For years, robots have been helping nuclear personnel meet ALARA requirements by reducing exposure to radiation—here's how indoor drones can help.

Every year, engineers and inspectors at nuclear plants will be exposed to some amount of radiation. While it is impossible to eliminate this exposure, the goal for plant operators is to try and reduce it as much as possible.

Interocean demonstrated their capabilities with the Elios 3 UT drone, shown here, to get class certified

In the U.S., this goal is legally mandated and described as ALARA, an acronym that stands for As Low As Reasonably Achievable.

According to ALARA, nuclear plant operators must take every reasonable step they can to reduce radiation exposure for their employees, while taking into account these variables:

- The state of technology

- The economics of improvements in relation to the state of technology

- The economics of improvements in relation to the benefits to the public health and safety

- Other societal and socioeconomic considerations (as applicable)

Unlike nuclear inspection standards, which describe specific protocols for how inspections must be conducted, ALARA is intentionally a little vague.

This vagueness comes from the words “reasonably achievable.”Given the constant evolution of technology, the complications of budgeting, and the daily constraints of running such a huge operation, each plant may have different capabilities when it comes to what they can do to lower dose exposure. The overarching emphasis of ALARA is on encouraging nuclear operators to do everything they possibly can to reduce exposure to radiation.

In fact, ALARA’s vagueness gives it a great deal of power. Rather than passively check a list of boxes to ensure compliance, nuclear operators must proactively weigh options, investigate new technologies, and constantly work to lower radiation exposure. Even if that reduction is only by 30 seconds per person, per year, this small improvement would be considered well worth implementing.

Seven Days of Work for a 20-Minute Inspection

All industrial inspections are known for being thorough, but nuclear inspections stand out as among the most meticulous of any industry.

Former NDT inspector Michael Vanovermeir, who now works for MFE Inspection Solutions, started his nuclear inspection career by working seven days to conduct a 20-minute inspection at a nuclear power plant. To perform the inspection he and his colleagues followed hundreds of steps, all of which were laid out in a large binder that had been made just for that one 20-minute survey.

Here is how the seven days surrounding that 20-minute inspection were spent:

- Three days of training for the inspection

- Two days performing the inspection walk down and preparation

- One day performing the inspection

- One day performing a post-inspection debrief to surface issues and make improvements for the future

This timeframe is typical. In fact, no planned inspection takes place in the nuclear industry without this level of detailed, methodical preparation, execution, and post-work debrief.

The timeframe—seven days for 20 minutes—reveals how incredibly important ALARA is to nuclear operators. At the center of all the work done in those seven days was a focus on reducing exposure as much as possible, no matter what was required to do so.

How Robotics Help with ALARA

Strategies for reducing exposure to radiation at nuclear plants typically fall into three categories:

- Time—reducing the amount of time someone spends in an irradiated environment.

- Shielding—wearing protective shielding to reduce radiation exposure.

- Distance—increasing the distance between personnel and an irradiated environment.

Of these three strategies, robots help nuclear inspectors by increasing the distance between them and the radiation in the environment where they need to conduct an inspection. Robots can also help reduce the amount of time spent in irradiated environments by doing work—like collecting visual inspection data—that a person would otherwise have to do.

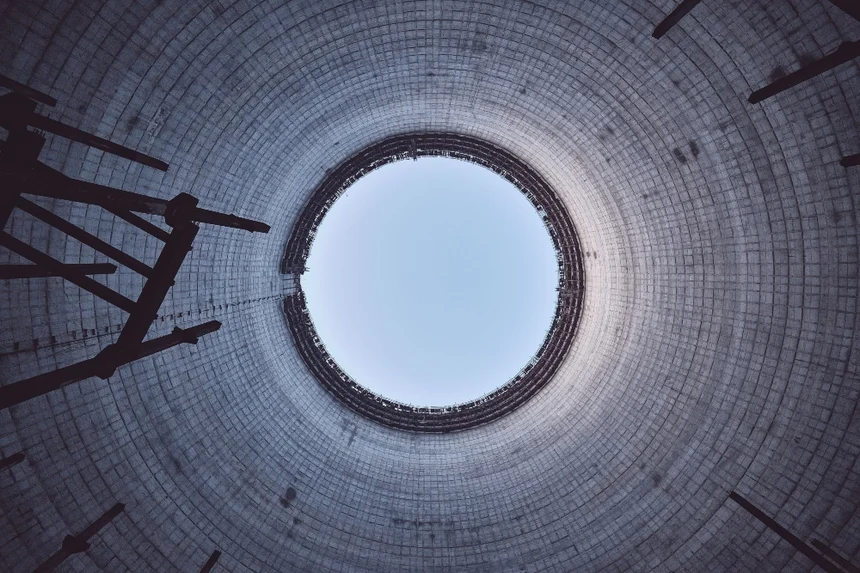

Nuclear sites have both radiation and non-radiation related inspections, such as cooling tower inspections

Because nuclear operators are always thinking about ALARA, they were early adopters of robotics solutions for inspections.

In most instances, robots can only replace people for some part of the inspection work that needs to be done at a nuclear plant, serving to reduce but not eliminate exposure to radiation. But, as noted above, even a very small reduction in exposure is well worth the cost and effort.

“The nuclear inspection process is grossly inefficient, and that’s by design. If you can reduce any of that inefficiency—even if it’s just by a single day, or even a few minutes—it can represent several million in potential savings from reduced downtimes.”

- Michael Vanovermeir, NDT Inspector

There are three main types of robots used for nuclear inspections: crawlers, ROVs, and UAVs.

Crawlers are small robots made to crawl on the ground or in pipes. ROVs are Remotely Operated Underwater Vehicles, which are made to operate in water. And UAVs are Uncrewed Aerial Vehicles—also known as drones.

Among UAVs, there are drones made to fly outdoors—this is the category most drones fall into—and then there are specialized indoor drones capable of flying in nuclear environments, like Flyability’s Elios 3.

The Elios 3 sits in a protective cage, allowing it to collide while flying in confined spaces and continue flying unharmed. It was created for internal inspections and can provide inspectors with high-quality visual data so they don’t have to enter a dangerous, potentially irradiated environment to collect it themselves.

The Elios 3 RAD: An Indoor Drone for Nuclear Operations

In the majority of inspections in the nuclear industry, robots can be used to collect visual data. This visual data can show inspectors what the conditions look like inside an irradiated environment, allowing them to reduce their exposure to radiation by removing the need for them to enter the area in person.

This visual data can show inspectors what the conditions look like inside an irradiated environment, allowing them to reduce their exposure to radiation by removing the need for them to enter the area in person.

When conducting inspections, nuclear inspectors will be looking for defects in the nuclear plant’s materials and assets that could get worse over time. For example, when inspecting the concrete dome of a nuclear reactor they’ll be looking for cracks in the concrete, and when reviewing the welding around the sleeves that hold plutonium or uranium they’ll be looking for places where the welding is starting to crack or corrode.

In almost any inspection scenario that arises in the nuclear sector, robotics can help to collect visual data. For external inspections, drones can fly up to a surface and collect visual footage showing its condition, just as crawlers can do for internal pipe inspections. For internal inspections, collision-tolerant indoor drones made to fly in confined spaces can fly very close to the surface being inspected, even in hard-to-reach places, helping inspectors to identify cracks or other defects.

New innovations in robotics have the potential to reduce radiation exposure even further by collecting other types of data remotely, presenting more ways for inspectors to reduce their time in and increase their distance from irradiated areas.

A new example of this kind of innovation for the nuclear sector is Flyability’s Elios 3 RAD, which is made just for work in nuclear plants.

The Elios 3 drone with the RAD payload mounted.

The Elios 3 drone with the RAD payload mounted.

The drone comes with three radiation sensors (also called radiation detectors). Each sensor covers a different range of radiation intensity and can be used interchangeably on the Elios 3 RAD, providing plant administrators with a robust set of data to help plan their operations and reduce overall dose exposure for plant personnel.

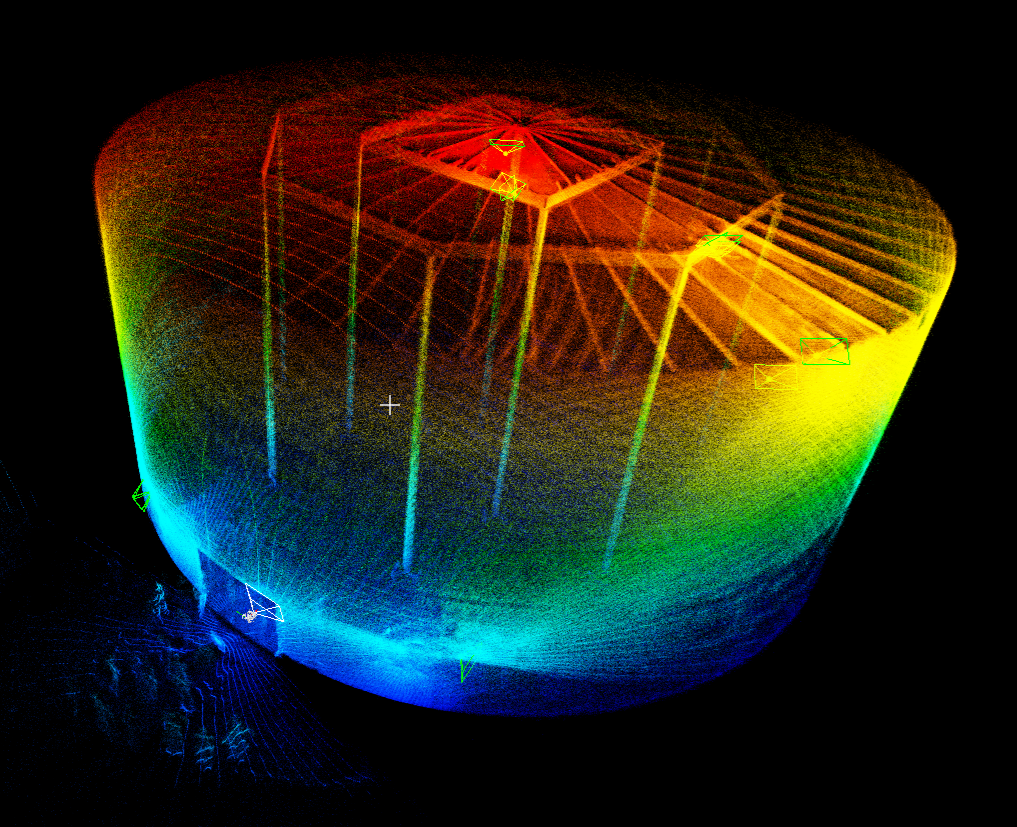

These sensors allow the drone to collect accurate radiation data while in flight. While flying, plant personnel can see a histogram from the last minute of measurement with a sampling rate of two seconds, which provides an indication of the maximum threshold present. Inspectors can choose between Rem and Sv units, get the instantaneous reading of the sensor, the cumulative dose for the flight, and the lifetime cumulative dose.

The data collected during the flight can then be used to map the dosage present within a given area so that nuclear operators can know the location of various levels of radiation within their plant. This radiation data can be used to identify hotspots, enhance the understanding of radiological conditions, and improve dose planning and decision-making—all of which can help people working at the plant reduce their potential exposure to radiation.

Nuclear plant personnel are already using the Elios 3 RAD to perform remote radiation sensing, allowing them to avoid entering irradiated areas to collect that information themselves.

This data is invaluable for project planning and for overall ALARA efforts, helping nuclear plants reduce the exposure plant personnel might face by letting them know how much radiation is present before they go into a given area.

Learn more about nuclear inspection drones like the Elios 3