Understand where to focus your maintenance efforts

Without the right data management solution, acting on raw drone data can be a real challenge, leading to approximative reporting, uncertain decisions, and sub-optimal maintenance planning.

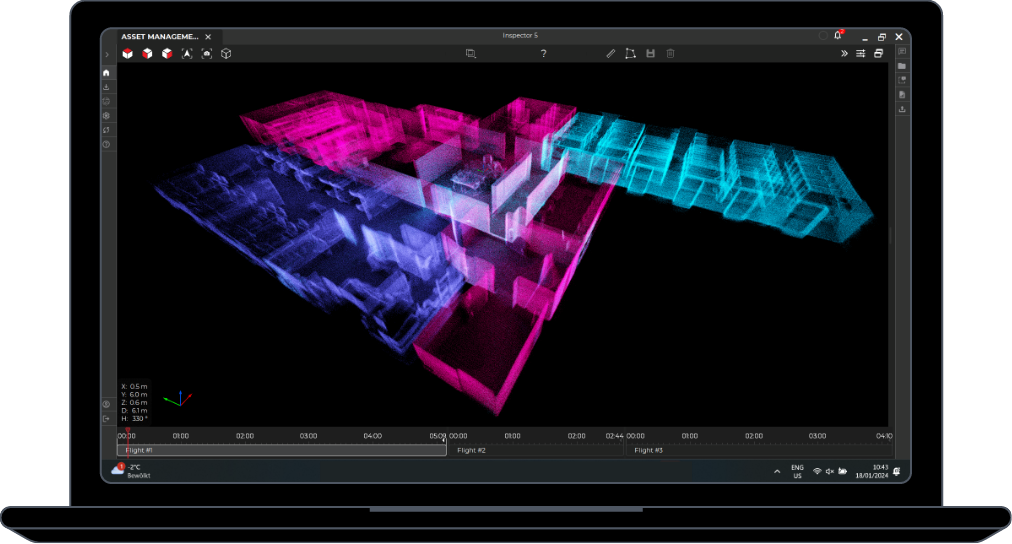

Inspector 5 and the Elios 3 work hand-in-hand in a seamless/continuous workflow to provide operational continuity throughout the inspection process. Flight data is organized by asset and can be instantly visualized in a digital twin of your asset—with no additional processing.

Localize with accuracy

Analyze with precision

Act with certainty

Convert raw drone data into valuable insights

Organize data by assets and inspections

Inspector 5 comes with a fully re-designed user interface letting you organize your flight data by assets and inspections. With the introduction of workspaces, you can group multiple assets together by project, customers, plants, or any segmentation criteria you like. This intuitive way of grouping flights allows you to easily navigate their inspection data ensuring intuitive accessibility as data enriches over time.

Localize defects on a digital twin of your asset

Visualize all data points from your flights in a high-resolution 3D map. Seamlessly navigate from one point to another by using the pan, rotate, and zoom functionalities. Click on a point of interest to instantly access the corresponding video frame, allowing for precise correlation of inspection data with real-time visuals.

Precisely analyze defects

In the video player, screen through video frames to select the one that best shows your point of interest. Zoom in and adjust the lighting and contrast as needed to enhance the smallest visual details. Utilize the Measurement tool to accurately size the defect.

Document and organize your POIs

Streamline your documentation workflow by recording your findings directly in the video player. Give your point of interest a name and a description, classify them by criticality and organize them with custom tags.

Share formatted reports

Compile your findings and insights into annotations. Filter and select the relevant information. Add your logo and export your analysis into a neatly formatted PDF report facilitating sharing and distribution within your organization or with your clients.