Why choose the Elios 3 UT drone for oil & gas inspections?

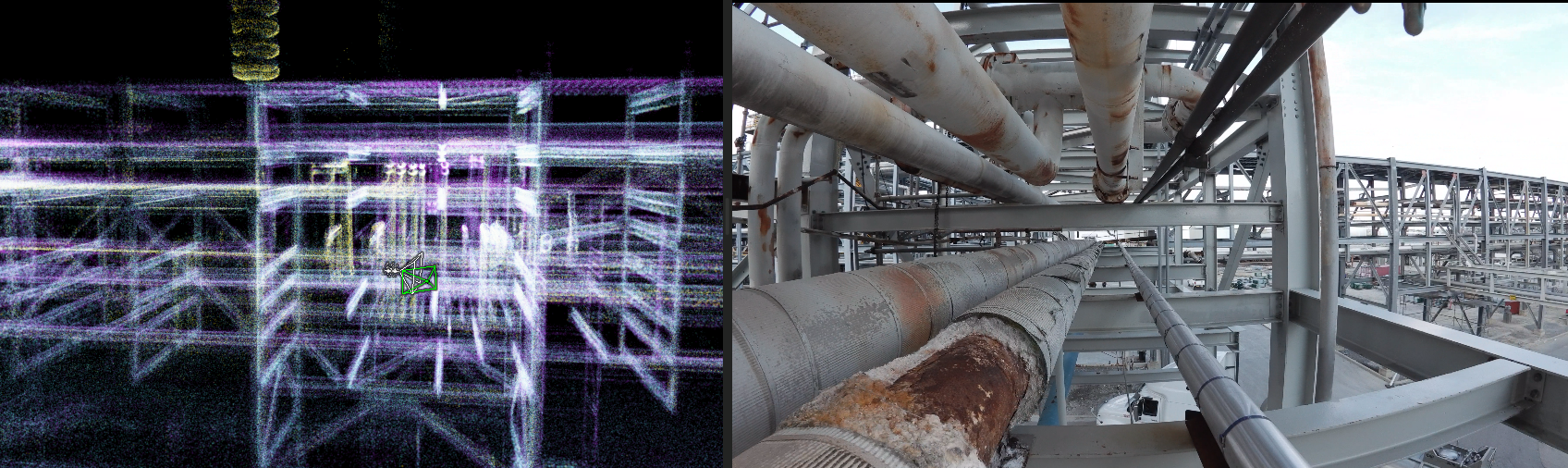

NDT drones are being used in the oil and gas industry to help reduce inspection time, cut costs, decrease asset downtime, and avoid sending people into confined spaces. What sets the Elios 3 UT apart from other UAVs is its ability to reach places no other drone can and collect API/EEMUA compliant data. Thanks to its unique design, this specialized NDT drone can easily access pipe racks, chimneys, storage tanks, flares, and distillation columns.

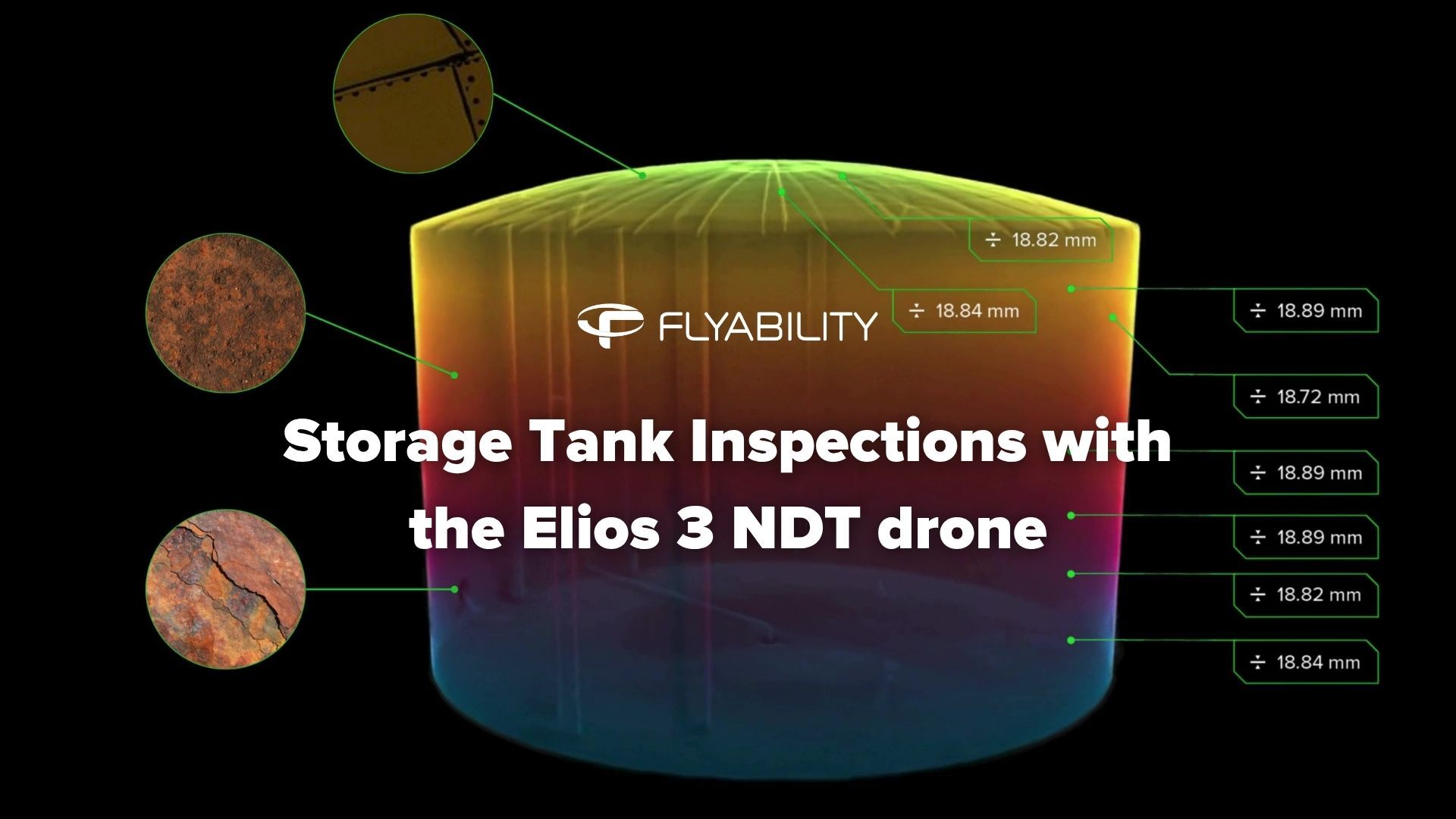

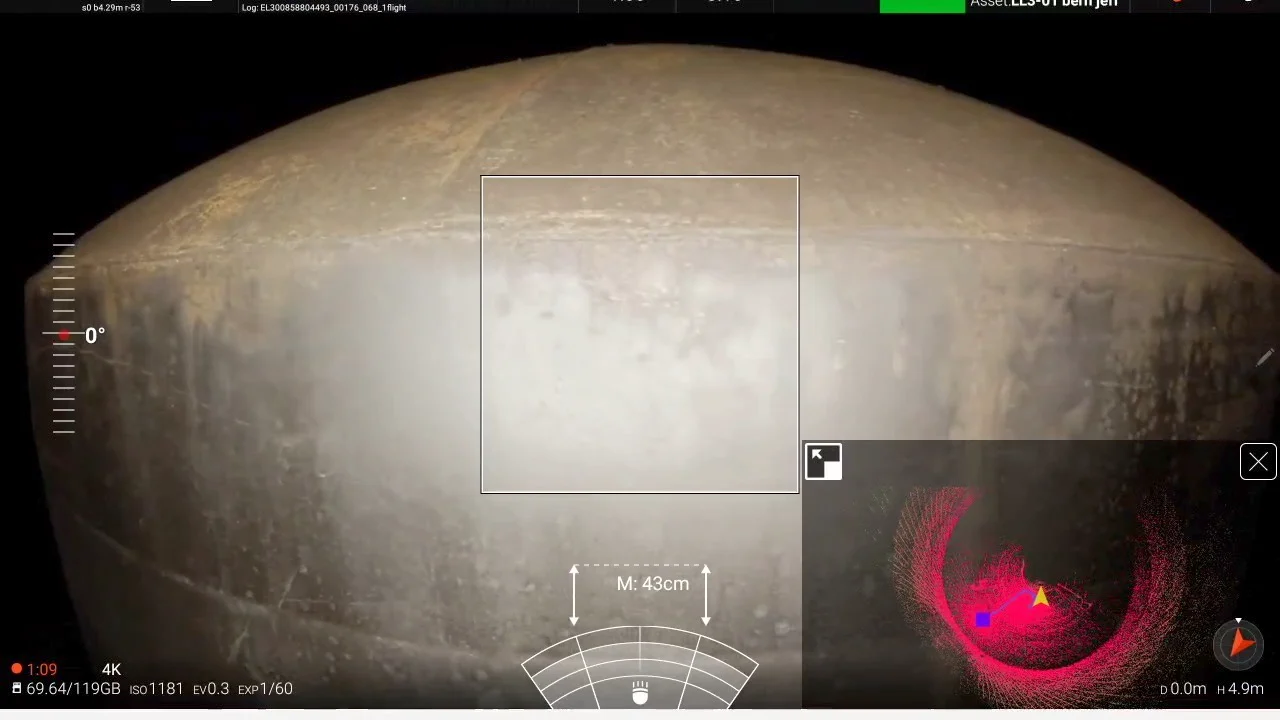

With the UT Payload mounted and the Tether Power Unit attached, the Elios 3 drone becomes a fully reliable NDT solution that allows inspectors to collect close-up visuals and up to 250 UTMs at height per hour. No need for expensive scaffolding, rope-access, or man lifts. In addition, the drone’s advanced LiDAR capabilities allow it to precisely localize defects in the digital twin of the asset for future reference and comparison.

-

Image represents: Digital twin of an oil tank captured by the Elios 3 showing the localized defect and UTMs collected during an inspection.

Why do 8/10 major oil and gas producers use NDT inspection drones?

Safety

Collect high-quality visuals and UT measurements without having to enter an asset and avoid work at height.

Efficiency

Cut inspection time by up to 80% and save $15k on tank inspections by avoiding scaffolding and rope access.

Data Quality

Get detailed visual, UT, and LiDAR data from inaccessible areas and benefit from precise data localization.

Collect reliable visual and NDT data across most oil and gas assets

Digitalize your oil and gas assets

Watch the Elios 3 NDT drone in action in the oil and gas industry

-

Safer oil and gas inspections with Elios 3

Read moreAsterios Lialios from Hellenic Petroleum and Evangelos Moraitis from DROBOTiQS discuss the role of confined space drones in the oil and gas industry. In particular, they touch on topics of safety and how drones are helping to make oil and gas operations safer. They compare traditional inspection methods, like scaffolding and cranes, with drone inspections and go through some of the major use cases for drones in oil and gas.

"I believe it's going to be a game-changer and a very important tool. Using a drone is inherently safe when compared to working at height or entering a confined space" says Asterios when talking about confined space drones.

-

NDT tank inspection with Elios 3

Read moreConduct a visual and UT inspection of a storage tank in just a few hours instead of weeks with the Elios 3 UT drone. No need to enter into the asset or to work at height thanks to the drone’s remote inspection capabilities.

Speed Efficiency Safety 4 hours instead of 2 weeks Save $30k+ on scaffolding and rope-access No human entry or work at height -

-1.jpg)

Offshore inspections at Shell with Elios

Read moreIn this video from Shell and CAN-USA, discover how drone technology is transforming offshore platform inspections, making them safer, faster, and more efficient. Using, among others, the Flyability Elios 3 drone, Tori is able to access hard-to-reach areas without the need for ropes, scaffolding, or putting herself at risk. And all that "in just 7 minutes".

The video takes you inside Tori’s inspiring journey from rope-access on Shell's offshore platforms to piloting cutting-edge drones equipped with cameras, thermal imaging, gas sensors, LiDARs, and ultrasonic thickness (UT) gauges. In this way, she and the team at CAN-USA can deliver accurate, real-time data in challenging offshore areas without being at risk. This approach not only reduces downtime and inspection costs but also improves safety for inspection teams.

-

FPSO inspection with Elios 3

Read moreTotalEnergies reduces inspection costs by 40% using the Elios 3 UT drone to perform its FPSO inspections. The Elios 3 collects data inside ballast tanks and provides accurate corrosion detection. Thanks to the LiDAR data, corrosion spots can then be localized in the 3D model of the vessel.

-

FCC inspection

Read moreUse a drone to perform visual inspections inside FCC units where the air quality is poor and the visibility is difficult for human eyes. Inspect all parts periodically to ensure the unit is safe for continued use.

Speed Cost Accuracy 4 hours vs 2.5 days and 170 work hours saved Avoid human entry and work at height +$100k saved in downtime -

Tank inspection workflow

Read moreRelying on the power of computer vision and LiDAR mapping, Elios 3 allows pilots to navigate inside industrial assets such as tanks, building a real-time 3D view of the drone’s environment and trajectory.

Speed Ease of use Accuracy Deploy a drone without the need for elaborated safety procedures or scaffolding During the flight, navigate through the 3D live map and visualize the drone’s trajectory Get detailed 3D insights, with 100% coverage -

Cooling tower inspection

Read moreA drone can help identify potential climbing hazards, find structural damage, and help inspectors understand the tools they need prior to climbing. Once this information has been gathered, the inspector can follow up and address the issues revealed in the data - if any.

-

Tank visual inspection

Read moreUse a drone to inspect areas that are difficult to reach and avoid any costs for scaffolding. Check the condition of welds, drains and inlets, corrosion coatings, screw connections and other components of the tank.

Speed Efficiency Safety 6 min flight to map the entire asset Eliminate scaffolding, inspect in a team of only two, and reduce asset downtime Avoid work at height and human entry -

Regenerator visual inspection

Read moreInspect a regenerator without having to rely on scaffolding or rope access, thanks to the innovative power of drones. Easily detect damage in the structure and capture beautiful 3D models without having to send people to inspect them.

Speed Efficiency Safety 6 min flight to map the entire asset Inspect in a team of only two and reduce asset downtime Avoid work at height and human entry

See how Elios 3 UT helps our clients save time, money, and stay safe

“

“The three biggest advantages of using the Elios 3 are the reduction of downtime of equipment, the reduced costs, and increasing the safety levels. Without having to put scaffolding inside the tank, we can save up to €15,000 per fixed roof tank inspection.”

Pieter Haxelmans

Inspections Engineer, TotalEnergies

They already use our products

-Jan-16-2026-10-59-56-8006-AM.png)