- Blog >

- Wind Turbine Inspection: A Guide

Conducting a wind turbine inspection is crucial for wind-powered energy's overall performance and longevity.

Wind turbine inspection is a tedious and dangerous process due to the extreme height and complexity of the turbine's design.

Inspections are critical to identifying core defects, delamination, internal damages, and other problems that result in decreased energy output.

What is a Wind Turbine Inspection and Why is It Important?

A wind turbine inspection entails inspecting the key components that allow a turbine to function and produce energy. Routine inspections are essential to monitor and mitigate wear and tear on the parts.

As the world advances towards a future of renewable energy, the job growth of wind turbine technicians is expected to grow 60% within the next decade.

While wind turbines are aimed at combating climate change, their blades, unfortunately, are beginning to litter landfills. Turbine blades are made of fiberglass and non-recyclable resins, with the average life expectancy around 25 years.

It may seem like a long time, but as more wind farms are built, the more this problem is exasperated. Therefore, it's imperative to increase the lifespan of the blades through regular inspections and preventive maintenance.

What Type of Inspections Are Commonly Done on Wind Turbine Blades?

Wind turbine inspections are not solely reserved for monitoring the operation of a turbine. The following lifecycle stages also benefit from continued monitoring:

-

During and post-manufacturing

-

Transporting the components to the work site

-

Building the turbines in the field

-

Inspect for warranty claims

-

Tracking construction progress of wind farms

-

Operational performance of the turbines

-

Preventative maintenance and damage assessment

Inspecting wind turbine components throughout each stage ensures that all stakeholders involved in the project are informed and assured of quality and performance. Additionally, wind farms are expensive to build and operate, meaning efficiency is vital.

Decreasing the levelized cost of energy (LCOE) continues to be an ongoing goal for the industry.

What Are the Critical Components of a Wind Turbine?

-

Turbine blades

-

Main bearings

-

Generators

-

Gearboxes

-

Nacelle (a protective component housing)

Blade Inspections

The blades on a wind turbine are tasked with spinning to convert kinetic energy into mechanical energy that's used to power homes, businesses, etc. Operational wear and exposure to the elements predispose the blades to damage.

As the demand for renewable energy increases, existing technologies are being retrofitted for optimal performance. For example, wind turbine blades are growing in size spanning over 260 feet.

To put that in perspective, that's longer than the wingspan of a Boeing 747. With a large surface area, more stress occurs on all turbine components.

With the expansion of wind farms, blade inspections are becoming an integral aspect of prevention and maintenance. Without the blades, there is no energy.

An offshore wind turbine with lightning damage

An offshore wind turbine with lightning damage

Wind Turbine Blade Inspection Methods

A wind turbine blade inspection is just one part of the overall process and is one of the more complex elements. A wind turbine blade consists of fiberglass and composite resins, prone to numerous issues when exposed to the right conditions. The slightest defect in a blade's surface can potentially reduce the aerodynamic efficiency, resulting in reduced energy output.

Surface Inspection

A surface inspection uses visual techniques such as cameras, drones, or the human eye to identify any issues. The following flaws are detected visually:

-

Surface cracks

-

Leading-edge erosion

-

Lightning strikes

-

Bird strikes

-

Delamination

-

Leading or trailing edge splits

The benefit of regular wind turbine inspections of the surface is performing corrective maintenance. Catching defects early on allows for repairs that prolong a component's life without reducing energy production.

Sub-Surface Inspection

The internal structure of turbine blades is susceptible to failures during the manufacturing process and in the field. Sub-surface inspections use the following methods to identify structural flaws:

-

Thermal Imaging

-

Shearography

-

Ultrasound (Acoustic)

-

Electromagnetic

-

Radiography

-

Visual inspection within the structure

Sub-surface inspections are non-destructive because of the contact-less technologies that can see through thick composite coatings without deconstructing them. The electromagnetic or ultrasound waves find defects when the wavelength becomes abnormal.

The ability to see through the surface helps identify damaged shear webs (structural blade supports), cracks, manufacturing damage, and bonding erosion.

Internal Inspection of Wind Turbines

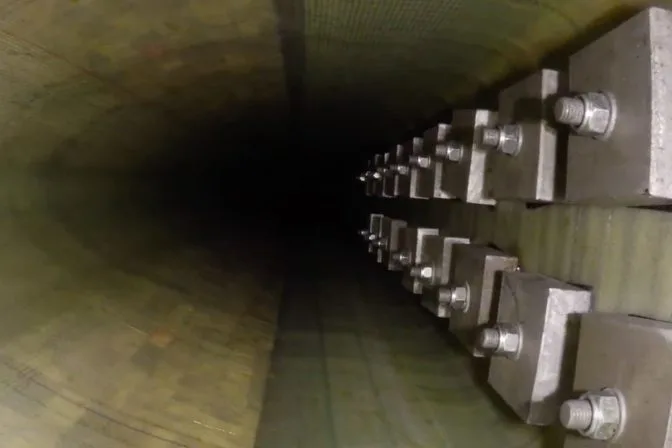

The final form of wind turbine inspection is physically going up into the turbine and climbing into each of the three blades. Technicians are legally only allowed to go 91ft (28m) inside the blade.

With many blades exceeding 200ft, over half of the internal structure is not being inspected. In addition, traversing into the blades is specialized work that's dangerous, expensive, and not efficient.

A blade is divided into two sections, and both must be visually inspected to check for cracks, missing or damaged hardware, and any defect that will result in failure. In offshore wind farms, internal corrosion from the salty air is another potential problem.

[Related content: What is a Maritime Drone?]

Some wind farms have several hundred wind turbines that need inspecting annually. Having to traverse into three blades with two compartments each is not a sustainable inspection method.

However, as the renewable energy industry adopts drone technology, inspection processes are improving rapidly.

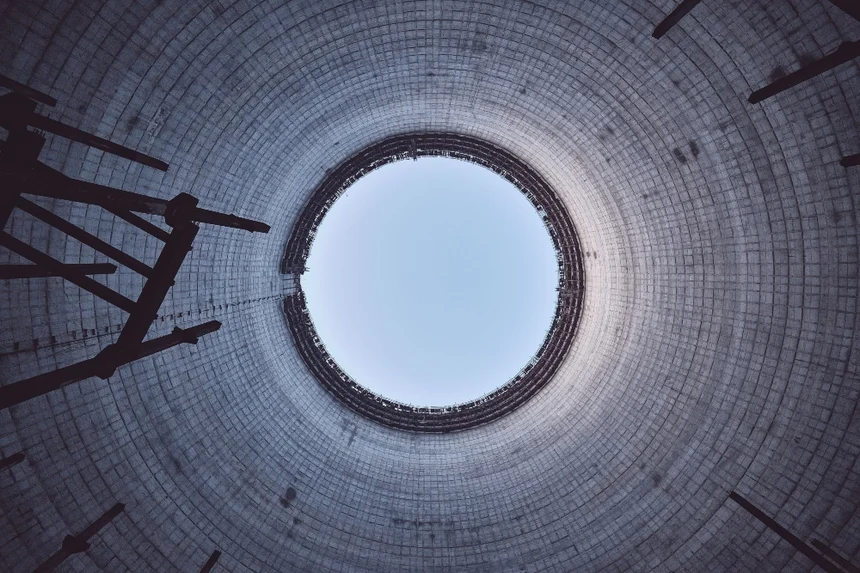

The inside of a wind turbine during an inspection

The inside of a wind turbine during an inspection

Traditional vs. Modern Wind Turbine Inspection

Rope access technicians perform the traditional inspection of wind turbines. These highly trained individuals utilize ropes and tethering systems to scale wind turbines for visual inspections, maintenance, and repair.

Turbines are turned off for manual inspections, and the blades are stopped in the six o'clock position. Once the team ascends the tower, they look for damage and knock on the blades to determine the condition of the materials.

Cons of Wind Turbine Rope Inspection

-

Turbines are shut off for hours resulting in loss of income and energy

-

Operating at high altitudes is dangerous and time consuming

-

Knocking on blades is not a sound method of determining the structure's strength

-

Wind noise and weather conditions make inspections difficult

-

Damaged wind turbine equipment puts workers in danger

The renewable energy sector is turning to drone technology to increase safety, efficiency, and revenue. A drone allows personnel to stay safe on the ground while the drone does the heavy lifting.

[Related read—Saving $1 million with Drone Wind Turbine Inspections]

Artificial intelligence and advanced sensors allow drones to assess real-time actionable data. A massive benefit of drones is that the turbine does not need to be turned off for specific inspections. Therefore, eliminating the reduction of energy and revenue loss.

A manual inspection platform for inspections by ropes

A manual inspection platform for inspections by ropes

Pros of Wind Turbine Drone Inspection

-

Some drone sensors are interchangeable for different types of inspections.

-

High efficiency with improved data collection times.

-

High-resolution images that identify defects the human eye can't detect.

-

Drones are used at both onshore and offshore wind farms.

-

The operational expense of drones is significantly lower than traditional methods.

-

Workers are not in danger at high altitudes and in cramped working environments.

-

Real-time data is viewed on a ground control station.

-

A wind turbine inspection drone is capable of inspecting the interior of blades.

As the world moves towards a clean energy future, the demand for wind turbine drone inspection will increase exponentially. More turbines will result in more inspections and the need for more intelligent and more efficient solutions.

How Often Are Wind Turbines Inspected?

Wind turbine inspection and maintenance schedules vary, but they are typically conducted two to three times a year. With the introduction of wind turbine drone inspection, there's potential for more inspections as drones are more efficient and cost-effective than traditional ones.

How Much does a Wind Turbine Drone Inspection Cost?

The cost of drone services varies based on equipment, location, and experience. In some areas, the estimated cost of using uncrewed aerial vehicles (UAV) ranges from $300-$500 per turbine, which is approximately 20-25% of manual inspections.

Read how using the Elios 3 for drone wind turbine inspections can provide savings up to $1 million.

Best Drones for Wind Turbine Inspection

Drones can cut both the inspection time and cost while increasing safety. The following are the best indoor and outdoor drones for a wind turbine inspection.

Internal Drone Solutions

The use of drones for wind farm inspections is still relatively new, and most drones are used for external inspections. That all changed with the Elios inspection drones from Flyability.

[Related read: Wind Turbine Blade Inspections with a Drone ]

Flyability Elios 3

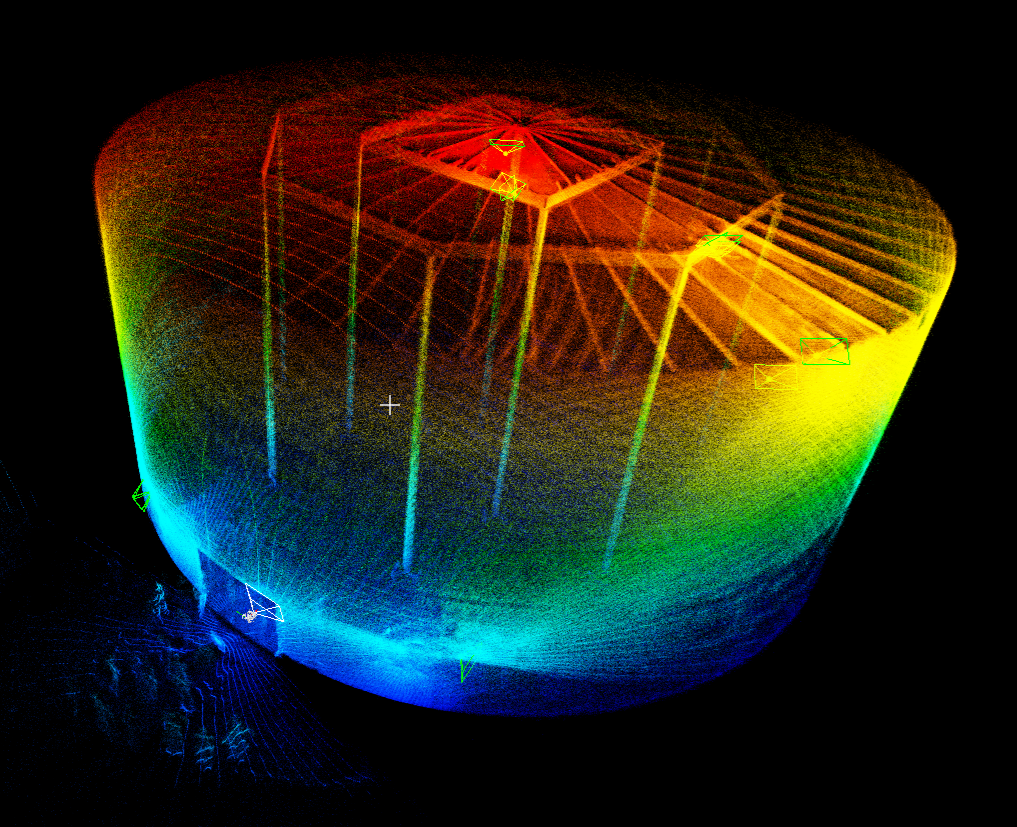

The Elios 3 is an indoor confined space tool designed to digitize the inaccessible and quickly convert data into digital insights. Its spherical enclosure and FlyAware software allow the drone to inspect the wind turbine blades autonomously.

An unobstructed dual thermal 4K camera works with the 16K lumen dust-proof lighting system to identify signs of cracking, corrosion, and structural issues, to name a few. The Elios 3 is future-proof with a modular payload bay with a dedicated LIDAR port and another for auxiliary payloads.

Utilizing the specialized inspection software, workers boost efficiency by understanding where to focus their maintenance efforts.

Flyability Elios 3 Specs / Features:

-

Dual Thermal/4K Camera Sensor: 12 megapixels HD live streaming

-

Lighting: 16K Lumen dustproof lighting with oblique lighting

-

LiDAR Mapping: Real-time 3D view of the drone’s trajectory and environment

-

Flight Time: 12 minutes

-

Flight Speed: Up to 7 m/s

-

Transmission System: Beyond visual line-of-sight

Are drones the future of wind turbine inspections?

The Elios 3 has proven benefits as a tool for wind turbine inspections. It improves safety while providing quality data and greater access to some of the most complex parts of a turbine.

With greater safety protocols being introduced globally, along with the rise of digitization, there is a clear need to integrate technology like drones or remote inspection solutions to meet the demands of these protocols. It wouldn't be difficult to imagine a future where drone inspections become the standard.

Interested in learning more or seeing a drone demonstration at your site? Talk to our team to book a demo!