Why choose the Elios 3 drone for mine inspections & mapping?

With its patented flight controller and collision-resilient technology, the Elios 3 can safely fit through openings as small as 50x50cm and collect comprehensive data in previously inaccessible areas.

When paired with the Surveying Payload and the FARO Connect software solution, Elios 3 can create centimeter-accurate scans of ore passes, draw points, and stopes, providing rapid insights that are not accessible with traditional tools or other UAV technologies.

-

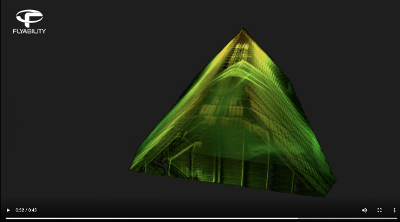

Image represents: 3D model showing the Elios 3’s trajectory and some of the points of interest recorded during the mission.

Benefits of integrating mining drones in your underground operations

Accessibility

Complete surveying tasks in areas that are unsafe or inaccessible to humans with traditional equipment.

Efficiency

Deliver centimeter-accurate data in minutes rather than hours and make informed decisions faster.

Safety

Avoid dangerous working conditions using remote monitoring, mapping, surveying, and inspection capabilities.

Access advanced drone capabilities for a range of mining applications

Accurate point clouds for mining

Exploring applications for our drones in the mining industry

-

.jpg)

Underground mine inspections at LKAB

Read moreAt LKAB’s Kiruna mine, one of the world’s largest underground iron ore mines, drones are transforming the way inspections are carried out. Production technician Daniel Jatko explains how the Elios 3 drone, equipped with a LiDAR scanner, has been a game-changer for the team. Its compact size allows it to navigate tight spaces like ore passes, crushers, and other heavy mining equipment, capturing both traditional video and 3D point cloud data. This innovation saves valuable production time, reduces costs, and provides highly accurate information for planning and maintenance.

Before drones, mining inspections often required scaffolding or putting workers in potentially dangerous situations, and in some areas, inspections weren’t possible at all. Now, LKAB can perform safer, faster, and more efficient checks, ensuring equipment integrity and mine safety without disrupting operations. The result is a significant boost in productivity and a major step forward in modernizing underground mining practices. -

.jpg)

Stope inspections and mapping

Read moreJoin us in an underground mine as he demonstrates how the Elios 3 with Surveying Payload transforms stope inspection and mapping.

Check out the mining UAV FREE factsheet 👉 https://bit.ly/4lsidmD

In this video, you’ll see how the Elios 3 drone performed a complete drone stope inspection from a single location in only 10 minutes, delivering 100% coverage with zero shadowing. Its ability to fly from 15 meters away from the ridge also made the process much safer for the inspection team. Watch how precise stope mapping with LiDAR and high-resolution visuals allows engineers to calculate extracted volumes and understand geological structures for better planning. The video covers the exact flight strategy to produce accurate point clouds and detailed wall imagery. This is a clear example of how drones are replacing slower, riskier traditional methods with faster, safer, and more complete data collection in active mining environments.

-

.jpg)

Ore pass mapping at LKAB

Read moreLKAB demonstrates how to efficiently map ore passes in its underground mine by using drones. Discover how the Kiruna mine adopted the Elios 3 mapping drone and transformed an 8-hour operation into a mere 20-minute job. Using the Elios 3 to inspect and map an ore pass, they managed to save ~7 hours of work and collect more accurate and complete data than previously possible.

Ore passes are critical vertical or steeply inclined shafts found in underground mines, responsible for moving extracted material from upper mining levels down to crushers or haulage systems below. Because they handle constant impact from falling rock, ore passes wear down, can become blocked, or develop structural issues, making regular inspections critical for both safety and production.

At LKAB's Kiruna mine, one of the largest underground iron ore mines in the world, they regularly inspect all of their 40 ore passes to make sure they are not getting too much wear. Deformations might lead to collapses or clogs. These vertical shafts are critical for transporting ore, but due to their hazardous environment, manual entry is not possible. -

.jpg)

Hang-up localizations

Read moreDiscover how the Elios 3 is changing the way mines tackle one of their most costly problems: hang-ups. In this video, we show how a US mine, after months of failed attempts using CMS scanners and drilling, could have saved millions and over two months of work with a single 10-minute Elios 3 flight.

Check out the FREE mining UAV factsheet 👉 https://bit.ly/4lsidmD

Watch how this advanced drone’s 3D live mapping and 4K visual feed enabled precise hang-up localization, revealing both the exact position and condition of the blockage inside a vertical raise. See why its compact design, collision-resistant cage, and ability to fly in inaccessible spaces make it the ultimate solution to localize hang-ups with drones, providing safer, faster, and more accurate results than traditional methods.

-

Old working inspections and mapping

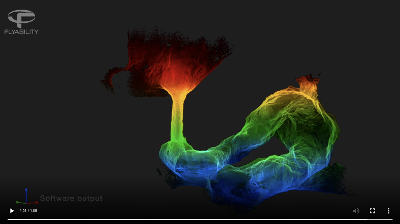

Old workings are extremely complex mining environments where you really don't want to send people inside. Join us as we explore how cutting-edge drone technology is revolutionizing old working mine inspections and exploration.Read more

Check out the FREE factsheet 👉 https://bit.ly/4lsidmD

In this video, we take you deep into an abandoned mine in upstate New York, where the Elios 3 was used for old workings exploration that hadn’t been accessed since the 1930s. Traditional inspection methods were too risky or incomplete, but with the Elios 3, engineers completed a full old workings inspection with drones in just 15 minutes, capturing high-resolution imagery and precise 3D LiDAR scans. Watch how the drone’s compact size, protective cage, and advanced navigation let it fly through narrow tunnels as small as 1.2 meters, mapping hazardous areas and identifying collapsed sections in real time. This project shows the future of old workings exploration with drones—safer, faster, and far more accurate than ever before. Whether for rehabilitation planning or safety assessments, this is a game-changer for mines worldwide. -

-1.jpg)

Progress Mapping at ICL Boulby

Progress mapping in mines refers to the process of regularly capturing and analyzing spatial data to monitor how mining activities are advancing over time. This includes tracking tunnel development, stope creation, or changes in excavation areas. Using technologies like LiDAR-equipped drones or scanners, operators can compare scans over days or weeks to measure advance rates, check against mine plans, and ensure targets are being met. It helps improve planning, safety, and operational efficiency.Read more

Progress mapping drones are specialized UAVs (unmanned aerial vehicles) equipped with LiDAR or photogrammetry sensors used to track and document changes in mining operations over time.

A team from Flyability traveled to ICL Boulby to test the new Ouster Rev 7 LiDAR payload in an environment already mapped with the original payload and see how the results compared. Mapping and surveying drones are becoming more and more relevant for mining inspections, which is why Elios 3 has adopted this new and more powerful LiDAR technology. Simon Pollitt, Chief Surveyor at ICL Boulby, shares his insights on testing the latest Elios 3 surveying payload and explains how they are using this drone for progress mapping. -

Draw point inspection

Read moreInspect a draw point from a safe distance and get 100% visibility from the inside. Do it in less time than it takes to set up a traditional CMS.

Speed Ease of use Accuracy 10 min to capture high resolution point cloud data Create a live 3D map and locate the drone and its exact trajectory Detailed 3D insights with 100% coverage -

Stockpile volumetry

Read moreWith the accurate LiDAR scanning, fully calculate your stockpile inventory and tighten up your forecasting.

Speed Safety Accuracy 9 min to capture the data with Elios (one flight) No work at height. The data is collected from a safe distance 3D models provide accurate stockpile calculations -

Ore pass inspection

Read morePerform regular ore pass monitoring and inspections to prevent hang-ups and keep the mine safe.

Speed Access Safety ~8 min to inspect 2 Ore passes and a small stope 100% data coverage even in no-go zones No workers exposed to hazards -

Equipment inspection & monitoring

Read moreEstablish standard procedures for routine inspections of heavy mining equipment, such as conveyor belts, ball mills, SAG mills, crushers, and stockpile feeders.

Speed Cost Efficiency Safety Deploy a drone on demand without the need for elaborated safety procedures and/or complex scaffolding Perform inspections without stopping the production with one pilot only vs. standard teams of 3-4 people No workers exposed to hazards -

Inspect large excavations

Read moreQuickly map and inspect large excavations to ensure they are in a safe condition.

Speed Access Safety Deploy a drone on demand without the need for complex safety procedures Get 100% data coverage—even in no-go zones No workers exposed to hazards

See how Elios 3 helps our clients save time, money, and stay safe

“

“Elios 3 can get into places that other drones can’t sneak into. I see it being a true replacement for human eyes underground.”

Meggan Gidden

Ground Control EIT, Glencore Kidd Operations

They already use our products

-Jul-11-2025-02-16-22-7528-PM.png?width=123&height=103&name=Untitled%20design%20(1)-Jul-11-2025-02-16-22-7528-PM.png)