- Blog >

- Interview: Class Certification for Maritime Drone...

In conversation with Steven Henderson and Alex Wilson of Interocean

Interocean Marine Services has been working for 25 years with a singular goal in mind: safe, professional, and quality services related to maritime assets. From design to surveys, inspections to maintenance, Interocean works with ship owners, oil and gas companies, and port managers to simplify the complexities behind maritime operations.

Part of how Interocean offers unique services has been their adoption of drone technology to enhance their decision-making and data collection. They have been using the Elios 2 for several years and in 2024, upgraded to the Elios 3 along with its UT payload. With this, they can make ultrasonic thickness measurements on ships and similar assets as part of inspections, maintenance, and class society surveys.

On September 30, 2024, Interocean announced they had been certified by major class societies ABS and DNV to complete ultrasonic thickness measurements with drones on mobile offshore units. This is one of the first official certifications for the drone to be used in this way for a service provider and marks an exciting step forward for the maritime industry as it adopts this new technology. Flyability talked to Steven Henderson and Alex Wilson from Interocean about their work and what this means for them.

Interocean demonstrated their capabilities with the Elios 3 UT drone, shown here, to get class certified

To get us started: tell us a bit about Interocean and what you do.

"Interocean has been completing offshore inspection work for 25 years, and we use lots of different types of technology to help us do this. With non-destructive testing methods, we determine the structural integrity and asset condition of various features. Sometimes access to testing areas is challenging so in the past, we used rope access, scaffolding, and mobile elevated work platforms (also known as MEWPs or cherry pickers). Now, we’ve started using the Elios 2 and Elios 3 to gain access and save us time and safety concerns. We also use underwater rovers when we can’t use aerial drones to continue gathering data remotely.

Typically, we work with marine insurance and marine warranty-related services, alongside helping move assets and inspect offshore infrastructure. We are involved in all parts of maritime asset management, from design to planning journeys to equipping an asset.

A priority for our team has been to use non-invasive techniques to assess assets offshore. There is a lot of pressure from clients when we are working on a floating platform or similar structure as inspectors reduce the number of personnel required on board, taking up bed space and potentially slowing down other operations. For that reason, our inspectors commit to working quickly and efficiently. Using technology like the Elios drones can help us speed up our inspections, improving our safety standards and also pleasing clients by reducing the disruption sometimes associated with an inspection."

Ultrasonic thickness measurements with a drone represent a gamechanging method for ship and offshore asset surveys that can keep people safer while maintaining data quality

Could you tell us a bit about what it means for class societies to approve your use of the drone?

"This achievement is hard to overstate. Class societies such as ABS and DNV set the standard for how we assess and certify ships and offshore assets. For them to approve the use of a certain testing method means that the technology has to meet strict requirements and be of proven value to the inspection process. The data provided by the Elios 3 and its UT payload has to be trusted by the society for it to be certified.

For us, most of our work falls under class rules. We do a lot of annual, bi-annual, or five-year inspections that need to be certified by class societies. Now that our drone technology has been approved for us by two societies, we can use this Elios 3 and its UT payload as a remote non-destructive testing tool to speed up our work without worrying about getting the results approved in a long and arduous process. We’re one of the first service providers to be certified in this way and we’re keen to put our advantage to use as we show clients what sets us apart from other inspectors or consultants."

Team members from Interocean analyzing results captured with the Elios 3 UT drone

What do you think of remote NDT technology like the Elios 3 and its UT payload?

"The benefits of the Elios drones are profound. There are always risk analysis procedures to follow. We can do some risk assessments before we reach the site but planning for specific permits as well as assessments done onboard can be slow. Using remote technology like the Elios drone as well as underwater rovers means we can reduce the number of permissions required, gather critical data, and keep our team safe. Receiving data more quickly is a brilliant benefit in itself, but the drone also provides the full context instead of just snapshots. This means we get to see what the data is like in real-time, viewing the flights for ourselves. The datasets with the drone are thus superior, both quantitative and qualitatively speaking. Remote NDT technology like this has a clear place in the maritime sector and we’re expecting to see it continue to be used."

Related Reading: What is a UT drone?

We’re biased - we love the Elios 3. What are the benefits you’ve seen it bring to your work?

There are a few key factors that we’ve noticed over the years when using the Elios 2 and now Elios 3. The drone naturally helps keep the team safe by reducing how much rope access or scaffolding we need along with fewer instances of confined space entry. Our data is better, and we can collect more than with previous methods, which is ideal for both us and our clients as it gives greater situational awareness. In addition, the use of drones is very easy to repeat. By doing inspections frequently and quickly, we can accurately demonstrate the deterioration rate, and this can be hugely beneficial to our clients. For example, if we do several inspections with the drone and prove that the deterioration or deprecation rate is lower than expected, there can be fewer inspections required in the future. This then optimizes schedule management for the asset owner.

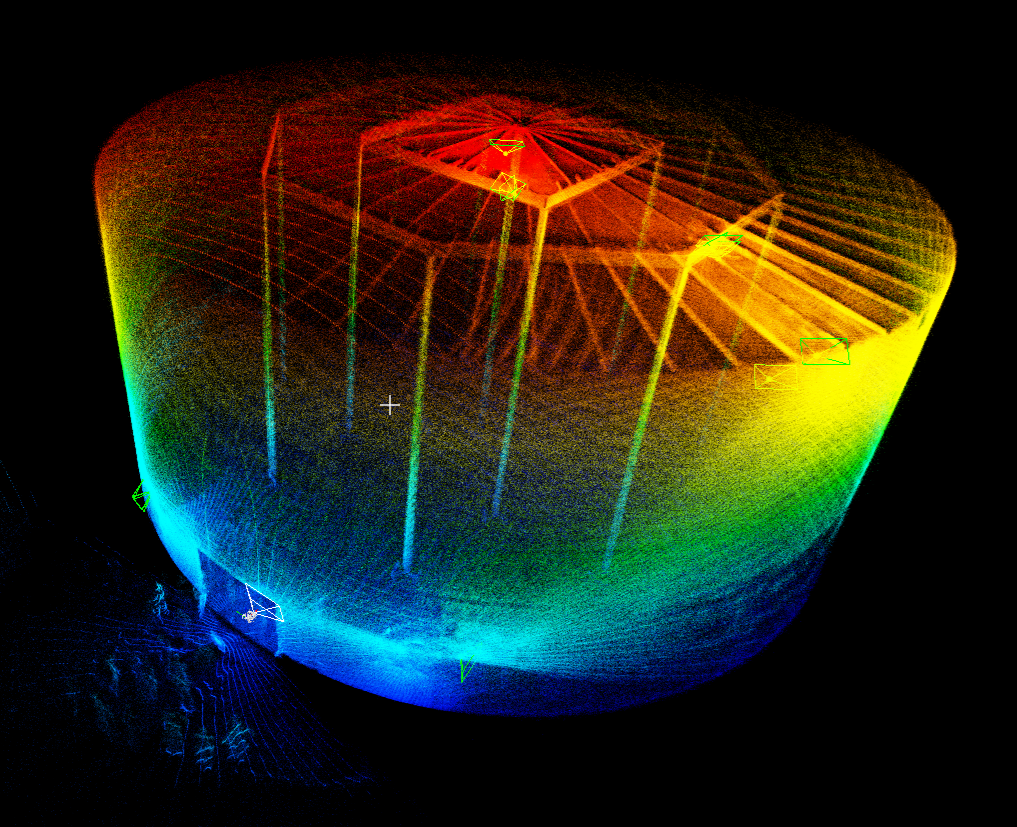

Finally, the Elios 3’s LiDAR payload helps to localize exactly where we’ve made a measurement or inspection before. We can then easily return to the exact same point another time, making sure we’re always tracking the same points of interest and gathering accurate data.

So, to summarise, I’d say we’re seeing the drone benefit us most in terms of safety, data quantity, and overall client relations.

Moving forward, what do you think comes next for Interocean and your UT drone?

"The class society approval means we can roll out the use of the Elios 3’s UT payload to our offshore work with confidence. The data we collect isn’t just useful for the asset owners but can be used as part of official certifications. It’s a huge step forward and speaks to the quality of our work and what we can achieve with our drone.

We hope that we can secure approval from other class societies as well as further applications to keep adding to the ways we are using this form of remote NDT inspections in the maritime sector. We can pitch to clients that we are bringing safer and more comprehensive inspections to their assets, setting ourselves apart from other service providers. We’ve got decades of experience to back us and new innovative technology to help us move forward. We are testing various new use cases currently, and we’re excited to share more about what we are doing with the UT drone next."