- Blog >

- What is Ultrasonic Testing? How does it work?

Industrial inspections stand between efficiency and disaster. An effective inspection can determine the state of an asset, be it a ship or pipe, and identify problems early on. An inspection can also be used to assess an existing problem, from leaks to biological hazards to breakages. There are thousands of inspection techniques in use around the world, with some specific to industry (like ship hull inspections) while others are more generic, such as steel thickness gauging. Under the umbrella of non-destructive testing comes a vital means of measuring the condition of asset material: ultrasonic testing.

What is Ultrasonic Testing

Ultrasonic testing is the process of using high-frequency sound waves to take measurements. The typical range of the sound range is 0.1 - 15 MHz and is produced with specialized ultrasonic testing equipment such as an ultrasonic probe or gauge. Ultrasonic testing (UT) is principally used to measure steel and other metallic material but is also deployed to measure the thickness of wood, concrete, and some other material. UT is often used to measure corrosion or abrasion in assets as well as to determine the integrity of asset walls or welds after a period of time.

How does Ultrasonic Testing work?

A simple explanation of UT is to think of it in terms of speakers and microphones. The probe has a speaker and microphone. During a measurement, the “speaker” will make a short sound and the “microphone” will record the emission of the first sound, as well as how long it takes that sound to be bounced back from the other side of the material. The distance between these two sounds/echos can be used to calculate the thickness of the material under test.

An ultrasonic testing probe being placed against a large pipe to measure its thickness

An ultrasonic testing probe being placed against a large pipe to measure its thickness

The real names for the “speaker” and “microphone” are piezoelectric transmitters and piezoelectric receivers, but can also be called piezoelectric transducers or piezoelectric sensors. To ensure the optimal transmission of sound through the material, many UT probes are used in partnership with some sort of couplant solution that eliminates the presence of air between the probe and wall, which stops the sound from being transmitted.

For a standard ultrasonic testing procedure, an inspector would prepare the surface to eliminate any dirt or residue, select an appropriately shaped probe for the environment, and calibrate the probe. After this, they would place the probe on the surface, eject couplant, and then take the measurement.

An example of a handheld ultrasonic thickness gauge

An example of a handheld ultrasonic thickness gauge

Ultrasonic testing is part of non-destructive testing (NDT), where materials are inspected to determine the current condition of that material with the intention of detecting faults or potential problems without compromising or damaging the material. It is used across industries as part of standardized inspections to ensure adherence with safety protocols, reduce downtime, and improve asset management.

Examples of assets and materials assessed with ultrasonic testing include weld inspections, ship surveys, and pipeline management amongst many other applications.

The methods an types of Ultrasonic Testing

There are several different versions of ultrasonic testing according to what material needs to be tested.

Pulse-Echo Testing, also called UT spot measurements, is the most common UT technique. This relies on a single transducer that transmits and receives sound waves, and can be used for testing some thin materials. This is typically used for standard UT surveys of walls or faults such as cracks or voids.

This diagram highlights how pulse-echo ultrasonic testing works

This diagram highlights how pulse-echo ultrasonic testing works

Phased Arry Ultrasonic Testing, with the acronym PAUT, this method will use a phased array transducer to complete inspections. A more advanced technique, it can be used in industrial NDT as well as some medical tests. PAUT is particularly useful for inspecting welds.

Pitch-Catch Testing: This method relies on 2 transducers, where material may be thicker. This is placed on either side of the test material or at two points along the material. Pitch-catch testing can be used to detect cracks, for spot measurements, and weld inspections.

Beyond the methods of ultrasonic testing, there are also several types of ultrasonic testing.

A-Scans are amplitude scans, and work in just 1 dimension. This means they only measure the thickness of the spot being measured.

B-Scans is a type of ultrasonic test that comprises of multiple A-scans. It is called 2D-dimensional, or sometimes a brightness scan, and measures the thickness of the wall across several different spots and creates a cross-section of the wall.

Some ultrasonic testing equipment, such as this handheld gauge, can measure both A-scans and B-scans.

Some ultrasonic testing equipment, such as this handheld gauge, can measure both A-scans and B-scans.

C-Scans are three dimensional scans. In this scan, sometimes called a color scan, the inspector is able to create a 3D map of the scanned area and present variations in thickness with different colors. These scans, along with B-scans, can be used in pressure vessels to identify pitting corrosion.

Ultrasonic Testing Equipment

The technology behind ultrasonic testing equipment has been rapidly evolving since its inception. There are several ways to gather ultrasonic testing measurements with current technology.

The type of ultrasonic testing equipment used will depend on the asset being inspected. While the majority of UT inspections can rely on spot measurements (A-scans), in cases where B or C scans are required, it may be necessary to purchase specific UT gauges. The vast majority of ultrasonic testing equipment used for non-destructive testing is handheld and/or highly portable.

A handheld UT probe is the most standard ultrasonic testing equipment. These tools comprise of a handheld logger and separate probe which are connected via a coax cable. The probe can be placed against a test point and the logger will show the value, with the option to adjust the gain and gates (the signal strength and how long the sound is measured) to get a clear reading for the material being tested. These probes can easily be used without causing damage to the surface, which is why ultrasonic testing is such a vital part of non-destructive testing.

A handheld ultrasonic testing gauge being used to inspect a weld

A handheld ultrasonic testing gauge being used to inspect a weld

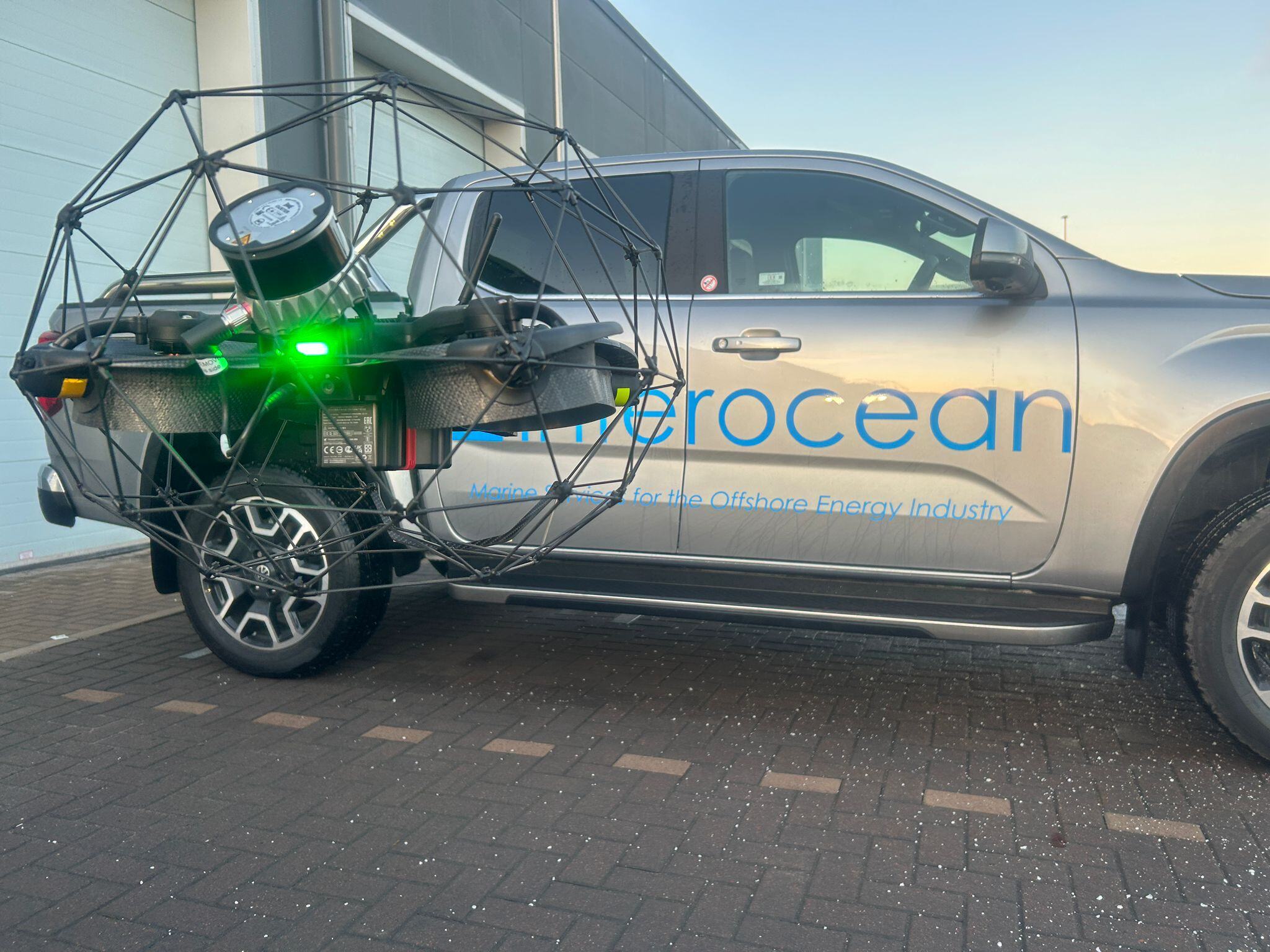

Today, some remote ultrasonic testing equipment has been developed. This includes mountain ultrasonic probes on drones and rovers. These can be very useful in gaining access to challenging environments, such as confined spaces or at height, where human access with a handheld probe may be hazardous or even impossible.

Using an ultrasonic testing equipment drone, or aerial UT drone, is a new and exciting area of development for drone-enabled non-destructive testing.

Introducing UT Drones

A UT drone is an unmanned aerial vehicle that is capable of taking ultrasonic thickness measurements. When using drone enabled ultrasonic testing, inspectors expect to see improvements in the safety, speed, and efficiency of an inspection.

In many cases, access to an ultrasonic testing site is straightforward. However, when that point may be at height, such as an industrial stack or the high walls of a ship hull, the reach of these locations becomes much more challenging. With UT stack inspections, it may even require removal of insulative material before the UT measurement can take palace. As an alternative, drone-enabled ultrasonic testing can reach these points quickly and safely. There’s no need for scaffolding, mobile elevated work platforms, or even rope access to gather data when a drone can fly up and use its probe to touch the measurement surface. This presents a huge improvement in safety practices for the inspectors while ensuring they still gather the data necessary to the inspection.

Similarly, this style of drone-enabled non-destructive testing, can get results much quicker than standard inspection methods. The scaffolding for a ship hull inspection can take up to 15,000 hours to mount and dismount, whereas ultrasonic testing equipment on a drone can gather that data in minutes. The drone also only requires teams of 2 people compared to the 10-person strong crews involved in erecting scaffolding. Thus, inspections can take place quickly and on-demand, with minimal downtime and fast results.

A UT drone taking an ultrasonic thickness measurement with a specialized UT gauge

A UT drone taking an ultrasonic thickness measurement with a specialized UT gauge

Finally, the overall efficiency of UT inspections is improved by a combination of the access of drones, their improved safety, and how non-destructive testing with drones can gather multiple types of data simultaneously. A UT drone with a powerful camera can take photos and videos for a close visual inspection and UT spot measurements in the same flight, streamlining non-destructive testing.

What is next for Ultrasonic Testing

With the rapid development of ultrasonic testing equipment to include remote options, it is likely that this area of non-destructive testing will soon evolve to help inspect new assets and material thanks to heightened access and safety measures.

The non-destructive testing market is hugely valuable, with estimates of it being valued at USD 14.28 billion in 2022. As most non-destructive testing includes visual inspections and ultrasonic testing or ultrasonic thickness measurements, this technology isn’t going anywhere. Now is the time to develop better and more efficient means of managing assets with ultrasonic testing - and perhaps ultrasonic testing drones are the way to do this!

-1.png)