- Blog >

- Bridge Inspections —Everything You Need to Know

Bridge Inspections —Everything You Need to Know

BRIDGE INSPECTIONS ARE A CRUCIAL PART OF MAINTAINING KEY INFRASTRUCTURE AND ENSURING SAFETY—LEARN MORE ABOUT THEM IN THIS GUIDE.

Bridge inspections allow engineers to identify small defects and potential problem areas in bridges before they develop into major issues.

If a problem in a bridge is not detected early, it could eventually lead to a catastrophic incident, such as a bridge failure or a complete collapse of the bridge, resulting in serious injury or even death.

And this is why bridge inspections are typically mandated by law throughout the world.

In this guide to bridge inspections we’re going to look at what is typically covered during a bridge inspection; bridge inspection types, techniques, and challenges; regulatory considerations; the work bridge inspectors do; and the benefits that drones can provide to help the inspection process.

What is a bridge inspection?

Though many of us may not think about the bridges we drive on every day, there are millions of them constantly in use throughout the world, and they all need to be maintained in order to prevent major accidents.

In the U.S. alone, there are over 700,000 bridges, all of which must be regularly inspected and maintenanced to ensure that they're safe to use.

Practices and regulations vary around the world, but most countries mandate that bridges be inspected at least once every two years.

In general, inspectors conducting a bridge inspection will be looking for any flaws, defects, or potential problem areas that may require maintenance.

The overall goal is to identify issues early, before they develop into bigger problems.

The traditional method for conducting a bridge inspection is to use a bucket truck—also called snooper trucks—designed to operate in rugged conditions, which allow inspectors to review the conditions underneath the bridge (as shown below).

A bridge inspection rental truck can climb steep inclines (up to 45 degrees), operate in deep water (up to 9 feet), and contain machinery that allows a person to sit in a bucket that can be lowered over the side of a bridge to give them a view of its underside.

Bridge Inspection Types, Techniques, and Challenges

There are many different types of bridges, and, accordingly, there are many different types of bridge inspections.

Here is an overview of the different types:

-

Periodic inspection. Also called a routine inspection, these are bridge inspections conducted as part of a legally mandated schedule. Inspectors conducting a periodic inspection will be looking at the condition of the bridge and noting changes between the last inspection and the current one, with the goal of ensuring that the bridge is still safe to operate according to existing standards.

-

Fracture-critical member inspection. This is an inspection of the parts of a bridge that are crucial for its stability, which are called “fracture-critical”—that is, the parts of the bridge which, if fractured, could cause it to collapse.

-

Underwater inspection. These inspections cover any underwater infrastructure that supports a bridge. Underwater inspections require diving equipment and specially-trained personnel.

-

Damage inspection. If damage is either known or suspected, engineers will call for an urgent, unscheduled damage inspection to assess the extent of the damage, its cause, and possible remedies.

BRIDGE INSPECTION TECHNIQUES

Although visual inspections are by far the most common type of technique inspectors use when inspecting a bridge, there are other techniques they may turn to, especially if they’re trying to learn more about a problem they've noticed.

Here are some of the main techniques inspectors use for bridge inspections:

-

Visual inspections. This is exactly what it sounds like—inspectors visually review the condition of the bridge in detail, either by standing directly in front of parts of it and looking at it or by using a Remote Visual Inspection (RVI) tool, like a drone, which can provide visual information to them remotely.

-

Acoustic inspections. With a hammer, chain drag, or some other tool inspectors observe changes in sound pitch on the bridge. Acoustic testing can be used to detect splits or separations in the materials used to make the bridge, such as delamination or coating splits.

-

Thermal inspections. Thermal or infrared data can detect changes in infrared radiation from the surface of a bridge, which could indicate degradation or delamination in the concrete.

-

Ground-penetrating radar (GPR). Using electromagnetic radiation, inspectors can create an image of the area below the concrete in a bridge to find defects such as cracks or delamination in the materials.

Finding the right technology for a bridge inspection can be particularly difficult, requirng inspectors to consider safety risks to people working at height while also gathering crucial data. Remote inspection techniques, such as using drones for railway bridge inspections, can help mitigate the risks.

UNIQUE CHALLENGES FOR BRIDGE INSPECTIONS

Bridge inspections come with their own unique set of challenges.

Here are some of the primary ones:

-

Traffic. Just getting a snooper truck into place can require an incredible amount of logistical planning. Traffic must be controlled on both sides of the bridge as well as on the bridge itself in order to provide room for the snooper truck to maneuver into place, and it must continue to be controlled throughout the inspection process.

-

Staffing. At a minimum, the snooper truck will need both a vehicle operator and an inspector to sit in the bucket, as well as additional personnel to help direct traffic.

-

Access. Even with the use of a snooper truck, getting access to all parts of a bridge so that they can be inspected can be extremely difficult since the spaces between girders, beams, or other parts of the bridge can be tight and hard to reach.

-

Cost. As you might imagine, snooper trucks are incredibly expensive. Buying one can cost over $600,000, and renting one can cost $2,500 a day. In addition to the cost of the truck, having the staff required to conduct a bridge inspection can also represent a significant cost, even for smaller bridges.

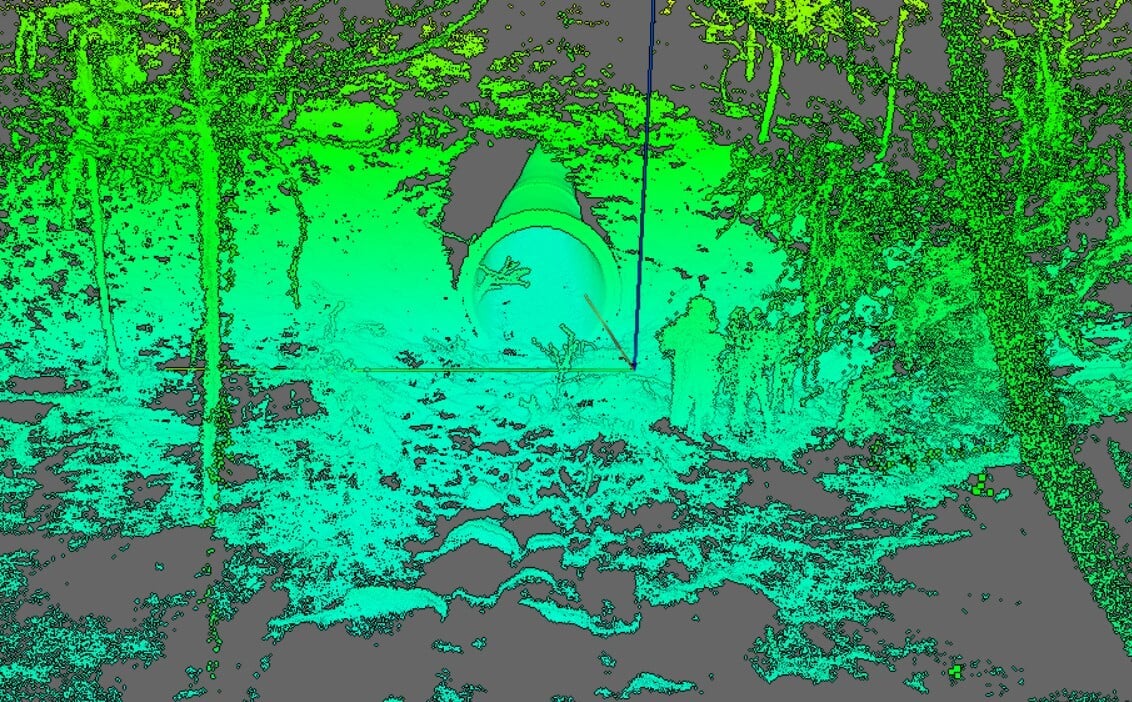

Some of these challenges can be mitigated by introducing new drone technology into inspection processes to help gather data and reduce risks to staff. Modern drones can reach inaccessible areas at height without disrupting traffic, such as in this bridge survey with an Elios drone.

Regulatory Considerations for Bridge Inspections

Every country has its own unique set of codes for bridge inspections.

These codes typically provide guidelines detailing:

-

The types of bridges that must be inspected

-

The regularity required for inspections

-

And the types of qualifications that the inspector must have in order to complete a bridge inspection that will be recognized by the law

In the U.S., for example, bridge inspections are governed by both federal and state guidelines.

Federal regulations for bridge inspections in the U.S. are provided in the National Bridge Inventory Standards (NBIS). Here is what these standards require as far as regularity of inspections are concerned:

-

Routine bridge inspections—Every 24 months

-

Fracture-critical member inspections—Every 24 months

-

Underwater inspections—Every 60 months

In addition to the NBIS guidelines, states often include additional conditions for bridge inspections, including:

-

Expanded definitions. Many states choose to expand the types of bridges that must be inspected (i.e., while NBIS standards may require inspections for bridges of 20 feet or longer, state guidelines may require them for even shorter bridges).

-

Increased frequency. Many states require bridge inspections to take place more frequently than NBIS guidelines mandate.

-

Variation of inspection types. Many states also vary the types of inspections required over a period of time, requiring, for example, several less in-depth inspections over a shorter period of time followed by an in-depth inspection every two years.

What Does a Bridge Inspector Do?

During a bridge inspection, an inspector will be looking for defects like cracking in the concrete, movement in the bridge that shouldn’t be present, or issues with bearings (if the bridge uses them).

Other signs of decay inspectors look for are rust, corrosion, or even paint loss, since these indications of wear and tear could point to deeper structural issues that might have arisen with the passage of time.

Electrical infrastructure is also a critical aspect to bridge inspections, but it can sometimes be under-emphasized, as inspectors focus primarily on fundamental structural issues.

To incorporate electrical considerations into bridge inspections, inspectors should be on the lookout for broken or out-of-date wiring, damage to the support structure that attaches wiring or other utility infrastructure to the bridge, and any other signs of old or poorly executed repairs in the electrical infrastructure on the bridge.

This infographic highlights the different parts of a bridge that an inspector may want to review when performing an inspection:

BRIDGE INSPECTION CERTIFICATION

Inspectors typically must hold some kind of bridge inspection certification in order to conduct an inspection of a bridge.

In the U.S., for example, the National Bridge Inspection Standards (the governing body for bridge inspections) mandates that the training bridge inspectors receive must be approved by the FHA (Federal Highway Administration).

Learn more about bridge inspection certification on the National Highway Institute's website or directly from the FHA.

BRIDGE INSPECTION STANDARDS

In most countries, the methods for conducting bridge inspections are defined by specific standards.

In the U.S., the Federal Highway Administration outlines specific criteria for how bridge inspections are conducted under the National Bridge Inspection Standards, which include: