- Case Studies >

- Inspecting a railway bridge inside and out with the Elios 3

Inspecting A Railway Bridge Inside And Out With The Elios 3

When a railway bridge across water proved difficult to access for an internal inspection, the Elios 3 provided the perfect solution to gather visual data while keeping operators safe.

Benefits In A Nutshell

|

Access An overwater railway bridge with internal assets was proving difficult to access until the Elios 3 was deployed to reach places people and crawlers could not. The drone was able to enter access hatches over land and water, making it easier to complete the inspection. |

Safety By using the Elios 3, this railway bridge inspection was completed without having to send anyone into the small steel girder running the length of the structure. This kept people from having to climb into the small access hatches and safely on the ground instead. |

|

Speed The flights with the Elios 3 were completed within a day, and results were shared with the client in time to facilitate fast decision-making by the railway bridge owner. The project was completed much faster than with traditional inspection methods. |

Results This project involved flying all of the external and internal elements of an overwater railway bridge. The complete visual inspection was used to carefully assess the condition of all elements of the bridge and identify maintenance requirements. |

Introduction

The railway industry faces a significant challenge: to innovate while being in constant use. In fact, the Australian rail industry alone has been steadily growing by 2% per year since 2010, according to Deloitte. Trains are getting faster while the loads they carry are getting heavier. Frequent inspections help rail operators to avoid accidents by keeping an up-to-date record of the status of all railway assets, from trains to bridges to tunnels.

Bridges that span waterways are traditionally difficult to inspect with a combination of regular rail traffic and difficult-to-access hatches, let alone the complexities of high-risk tasks such as confined space and rope access. However, these bridges are also exposed to greater stresses due to potential metal corrosion by water - especially in coastal settings. So, although a rail bridge inspection may be challenging, it is still critically important to the overall railway network.

Customer Needs: A Railway Bridge Inspection With Drones

A bridge in Port Adelaide, Australia needed an internal and external inspection on the bridge carrying the Dry Creek railway line over the Port River. The asset owner had recently awarded an inspection campaign to an Australia-based engineering firm. This firm has previously worked with Azure Integrity, a specialist drone service provider, and has seen the benefits of utilizing RPAS solutions. With confidence in this method, the engineering firm decided to carry out both an external and internal inspection of the bridge using drones, the internal inspection of the steel box girder posing the biggest challenge.

Azure Integrity is an industrial drone service provider based in Adelaide, Australia. As previous users of the Elios 2, they bought an Elios 3 in 2023 and their team is currently using it on a variety of sites. Their projects range from infrastructure inspections in railways to industrial environments, oil & gas, mining, and more. They recently completed a successful culvert inspection on a mining site in Queensland, Australia with the Elios 3. Since then, the Elios 3 has accounted for 50% of Azure Integrity's operations, further growing the awareness of their service offerings within Australia.

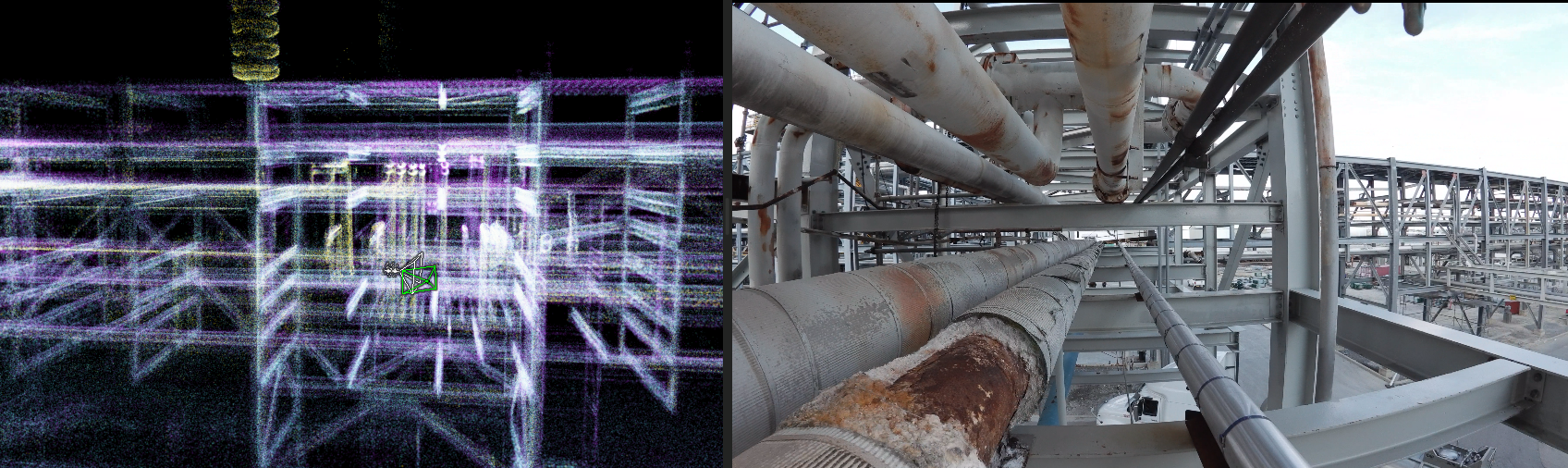

The Azure Integrity team conducted both internal and external bridge inspections with the drone.

As part of the pre-works carried out by Azure, they were able to establish that the steel box girder was greater than the 500x500mm dimensions necessary for the Elios 3 to enter. A further assessment was carried out to determine if the Elios 3 was the correct solution for the task. With the internal complexities of the angled support beams and reinforced sections reducing the dimensions of the girder, it was confirmed that using a crawler or confined space entry team would not achieve the full inspection safely or efficiently.

Solution: Saving The Day With The Elios 3

Azure Integrity sent a team with the Elios 3 to carry out the inspection. Their pre-works assessment had shown that it was a complex location: elements of the bridge over the Port River had 1 access hatch on dry land and 1 over water. This was a major consideration for using drone solutions for the inspection, as it would provide safer access than traditional inspection methods.

Azure Integrity was able to complete an entire bridge inspection that started with the external flight. This comprised of skilled flying; inspecting the piers, abutments, and substructure bearings as well as the main body of the bridge, where the concrete was closely visually inspected to assess its current condition. This data was captured with a combination of the external RPAS and also the Elios 3 using its powerful 4K camera to get close to the bearings.

Due to the large size of the bridge and the range of components being inspected, the Azure team tactically split the flights by taking off from different sides of the bridge.

The internal space in the steel girder was small and hard to access, which is why the Elios 3 was used.

Next, the team moved to the internal inspection of the girder. The Elios 3 entered the girder with plenty of space and moved along each span before maneuvering through the tighter sections of the structure. These sections were tighter due to the steel girder being supported by external concrete pillars which required the pilot to carefully fly the Elios 3 into the narrower space. This was confidently done through a combination of the Elios 3’s powerful 16,000-lumen lighting system, collision tolerant cage around the drone, and the skillset of the pilot.

Once the inspection was completed, as part of Azure Integrity’s processes, the data was checked on-site to ensure they had gathered enough high-quality data to carry out a desktop inspection of the entire bridge before they returned to the office to allow the engineers to prepare their report.

Conclusion: Setting Drone Inspection Services Apart From Traditional Methods

By combining Azure Integrity's skillset, advanced robotic solutions, and this technology’s ability to empower engineering clients and asset owners, a comprehensive assessment of the bridge was provided with no risk to personnel. In addition, the task was completed a fraction of the time typically required of traditional methods.

The use of the Elios 3 was the only way to get an accurate inspection of the inside of the steel girder due to its complex structure. It was too small for a person and too complex for a crawler.

As the Elios 3 continues to prove its merit in being a faster, safer alternative to traditional inspection methods, more projects are being opened up. Azure Integrity continues to set themselves apart from competitors as they complete successful projects with their Elios 3, expanding their drone inspection service portfolio with almost every flight.

Discover more about the Elios 3 and its applications

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)