- Case Studies >

- Inspecting 63 tanks with 2 drones in 2 weeks

Inspecting 63 Tanks With 2 Drones In 2 Weeks

The Elios drone helped TDBR Inspections revolutionize tank inspections at the 3R-2 rig off the coast of Brazil

Benefits In A Nutshell

|

Speed The Elios 2 and Elios 3 completed inspections of 63 tanks in 14 days with just 2 members of staff. In the past this would take months to complete with 3 or more staff required. |

Safety Due to using drones, there was no need to send people inside the tanks or to work at height. Because no human entry was required, it removed the need for special permits, making everything more efficient. |

|

Accuracy |

Efficiency As a result of completing the inspections with drones, the number of people on board (PoB) the rig was never exceeded and was better optimized to have engineers and workers on-site instead of inspection teams.

|

When working offshore, you face a unique set of challenges. If equipment fails, or material has not been delivered, you can face long delays, downtime, or even potential hazards. However, as every inch of space counts, there is a balance to be struck between inspection and maintenance, operational procedures, and the efficiency of the site.

Customer Needs: Challenging Inspections For An Offshore Rig

For 3R-2, a TLWP-type oil rig off the coast of Brazil, major inspections pose a challenge. There is a maximum number of people on board (PoB) of about 60 people. Those 60 need to include engineers, operators, and general staff. Staff are transported there by helicopter, and optimizing the PoB number as well as their transport on/off the platform helps streamline work without putting strain on staff or the site’s operations.

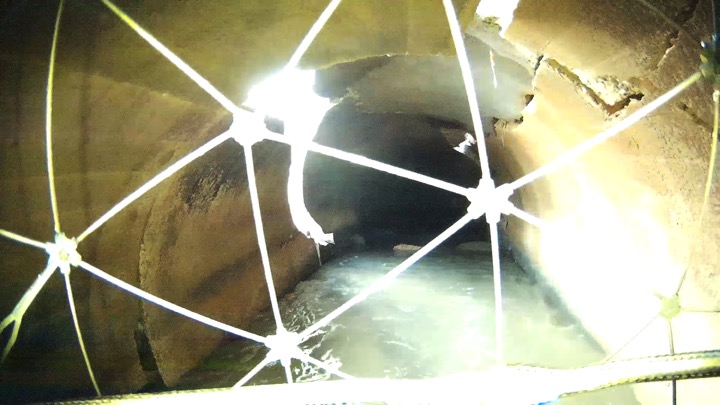

The tanks being inspected are very high, making them difficult to inspect manually

However, inspections of assets including tanks onboard can be difficult. The 3R2 has several large tanks onboard, and to inspect them requires several members of staff using ropes, and can take multiple days per tank. The facility is 10 years old and held to very high regulatory standards. This means that any inspections need to be thorough as the results will be used to update existing records. The question is: is there a way to get those results without bringing large teams of inspectors on board for prolonged periods of time? Finding the balance can optimize the PoB as well as streamline inspections and data management.

Solution: Using Drone Inspections To Save Time

TDBR Inspections, a drone service provider in Brazil, has significant experience in completing complex inspections with the Elios drone. They were contacted by Raul Martini, a naval engineer specialist from 3R Petroleum who owns the 3R-2. They aimed to complete tank inspections with the Elios drone and see if they could save time at the rig.

The Elios 2 (upper) and Elios 3 (lower) outside the narrow entry for a tank

The Elios 2 (upper) and Elios 3 (lower) outside the narrow entry for a tank

The aim was to gather visual data concerning the status of large tanks. TerraDrone needed to build up an archive of relevant imagery that could be used for visual inspections, checking for defects, and identifying faults. Areas of interest could then be identified and marked with special paint to highlight areas needing work. The project would be immense, with over 70 tanks at the site. TDBR Inspections planned to visit 3R-2 on four occasions and gather data.

The key benefit of using the Elios drone would be the time and cost savings, but also the simplified logistics. To enter a tank of this nature for an inspection requires a special permit for entrance - but a drone requires no such pre-authorization. In addition, the results were to be submitted to the Class society to verify the accuracy. If successful, this project could present a potential partnership between TerraDrone and 3R Petroleum to routinely conduct inspections on 3R-2 with the Elios drone.

Results: Inspecting 63 Tanks In 88 Flights

A team from TDBR Inspections traveled to the 3R-2 and began planning how their flights would take place. This was part of Phase 1 of the project. They scouted the tanks with an Elios 2, completing reconnaissance flights and planning to enter the assets.

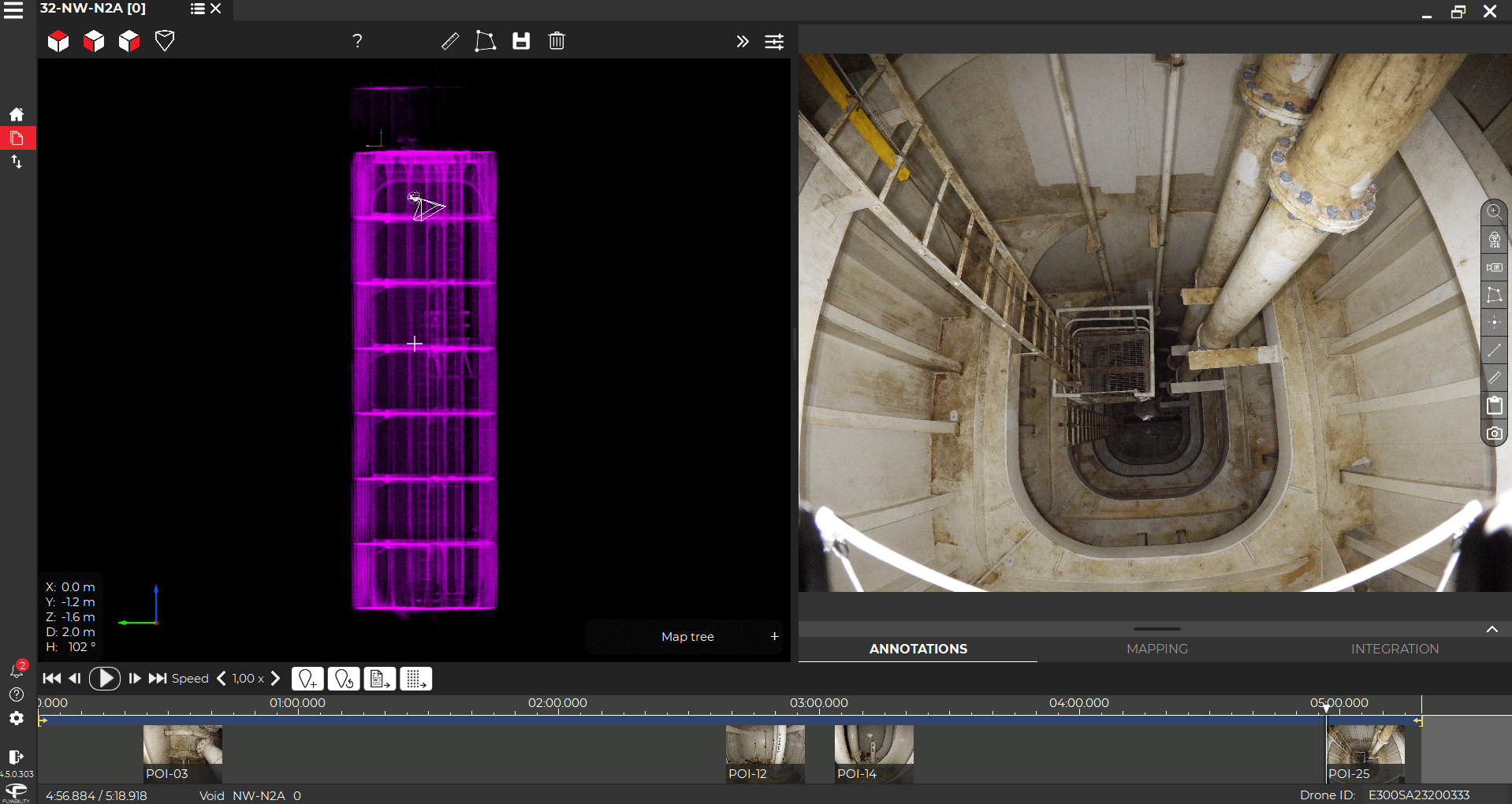

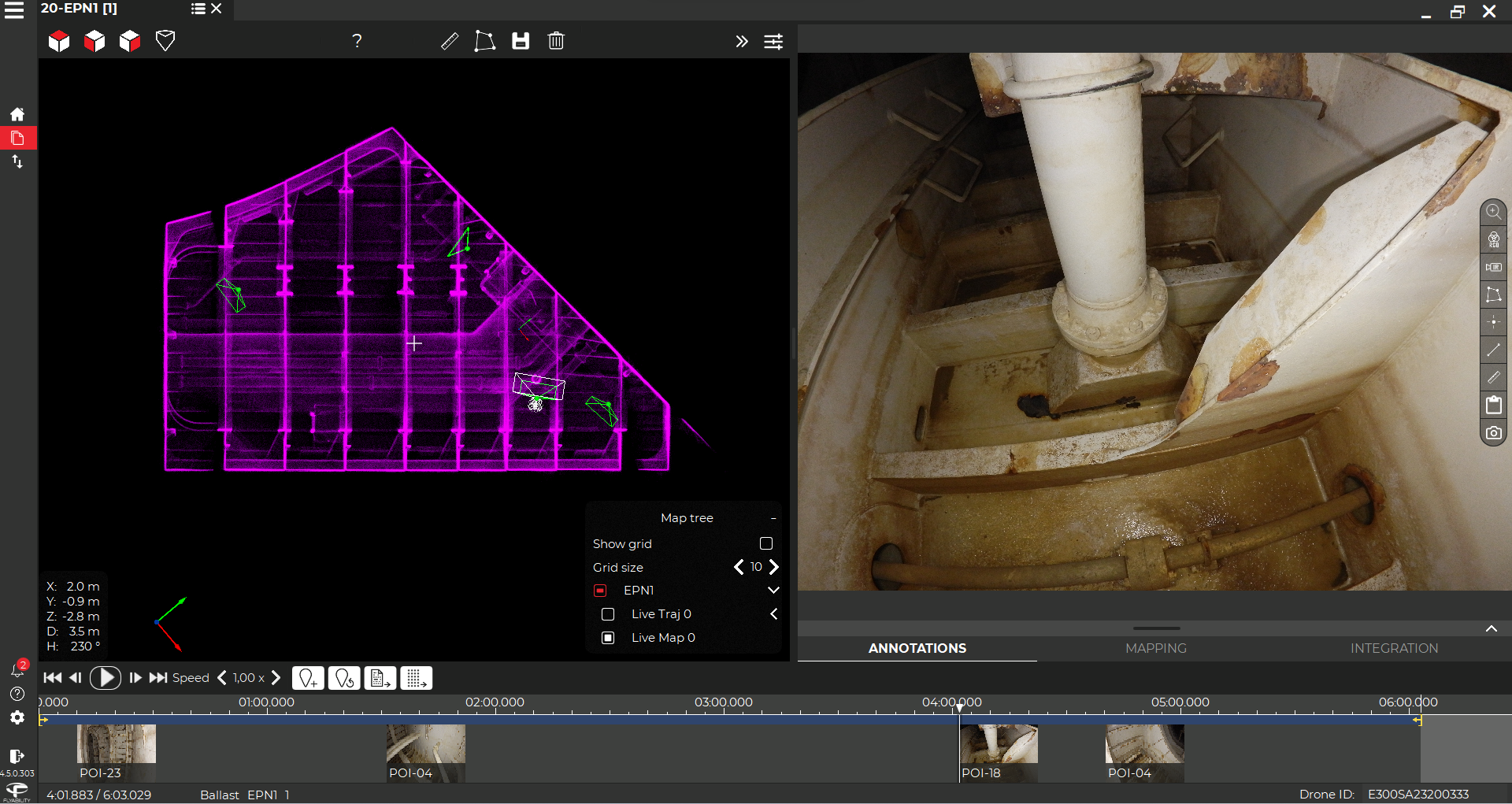

The inside of a ballast tank visualized with the Elios 3

After some initial external inspection flights as part of Phase 1, the TDBR Inspections team returned a month later to begin Phase 2. During that month, they bought an Elios 3 and brought it as well as the Elios 2 to the 3R-2.

Over the course of 14 days, TDBR Inspections’ pilots flew 88 separate flights in and around 63 tanks. It took over 10 hours of air time and involved using both the Elios 2 and Elios 3.

After the flights were completed, the data was processed in Inspector 4. Visual inspections from both drones were used to update existing records and search for anomalies, whilst the Elios 3’s LiDAR data was used to create 3D models of the inside of the tanks. These models provided clear information about the conditions of the tanks, and made it possible to get detailed knowledge about the assets without anyone entering the confined spaces.

Conclusion: A Longterm Strategy For Faster Rig Inspections

The scale of this project cannot be overstated - by inspecting 63 tanks in 2 weeks, the team was inspecting over 10 assets per day. This pales in comparison to traditional methods. For example, on an FSPO, tank inspections require up to 4 or 5 rope access technicians, and it can take up to a week to complete the inspection. With an Elios 3, it took 2 people just 2 days per tank.

Moving forward, TDBR Inspections expects to repeat inspections of this nature at 3R-2 and other similar sites. Their operational efficiency alone brought significant time and cost savings to the managers at 3R-2, as well as optimized the movement of staff and inspectors - helping solve the challenge of the number of PoB. Not only was the Elios able to keep people safe and out of confined spaces, but it gathered data that matched the regulatory requirements of the Class Society, and helped solve a real industry-wide challenge.

Discover more about the Elios 3 and its applications