- Case Studies >

- Testing the Elios 3 Surveying Payload: Mapping a 600m...

Testing The Elios 3 Surveying Payload: Mapping A 600m Bridge Without Disrupting Traffic

Flyability and our partner Droprise used the Elios 3 and its new LiDAR payload for a road bridge survey in Belgium.

|

Safety |

Efficiency |

|

Accuracy The Surveying Payload is capable of over 90% data collection to within 1 centimeter, providing a high degree of detail and accuracy in results. |

Business Development To avoid distracting traffic, no flights were done directly over the live bridge deck. Despite this, it was possible to recreate the entirety of the bridge within the desired survey area. |

Flyability launched the Elios 3 Surveying Payload in October of 2023 intending to provide a LiDAR payload for our flagship drone that can do more - it has features that enable greater data coverage, mapping efficiency, and accuracy. With their partner Droprise, they tested the use of the Elios 3’s new payload for a road bridge survey.

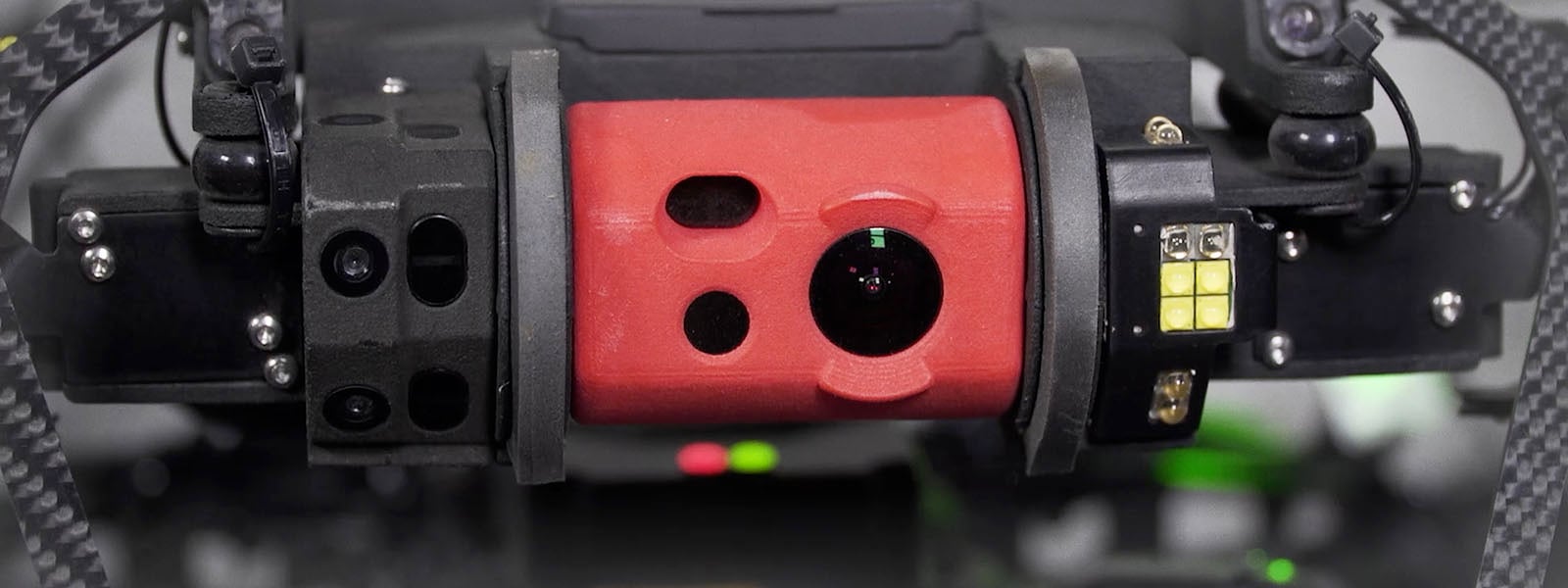

Understanding the Elios 3 LiDAR payloads

Professional drone inspectors and surveyors can choose between the Elios 3’s two LiDAR payloads according to what best suits their needs.

The standard configuration, with the Rev 6.2 LiDAR, is better suited for projects where a general overview of an area is needed with a moderate requirement for accuracy.

The Surveying Payload, on the other hand, is tailored for scenarios where accuracy is paramount. It uses the Rev 7 LiDAR and is best suited for surveying challenging and complex environments including underground mines, wastewater pipes, and sewers, as well as projects that require centimeter-accurate results.

The new Elios 3 LiDAR payload can unlock more capabilities than the standard Rev 6.2

The new Elios 3 LiDAR payload can unlock more capabilities than the standard Rev 6.2

The new payload aims to bridge data gaps in challenging environments. This is achieved through its enhanced physical capabilities as well as partner processing software FARO Connect. The Surveying Payload’s capabilities are astonishing; in testing over 90% of data gathered was accurate to within 2cm, with 1.3 million points scanned per second and a range of up to 100 meters. Data processing with FARO Connect enabled the automated merging of point clouds as well as automatic noise reduction thanks to processing settings designed for Flyability drones.

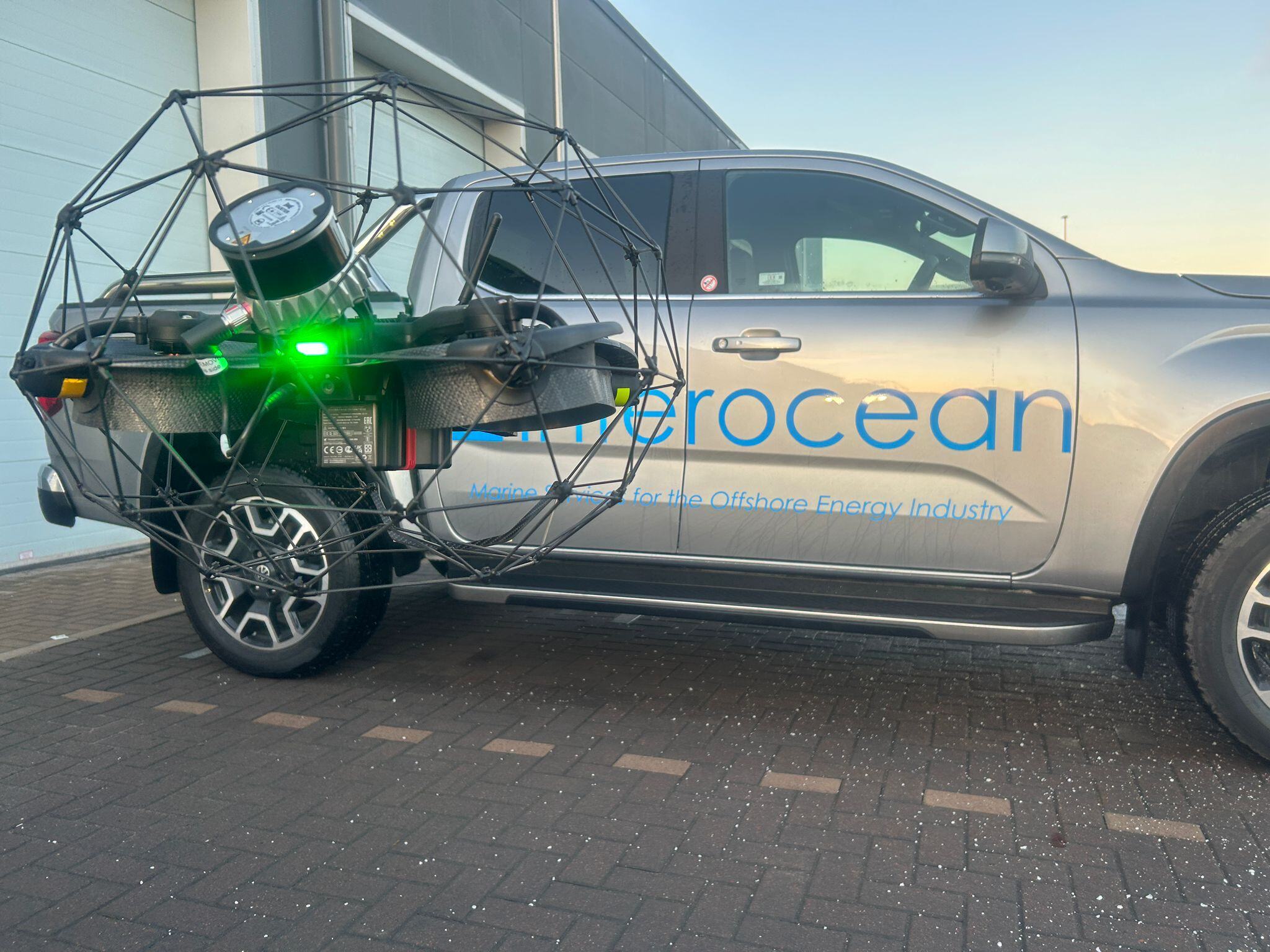

In October 2023, Droprise and Flyability took the Surveying Payload and Elios 3 out to a new site to demonstrate its capabilities in a unique mapping environment.

Completing a road bridge survey without stopping traffic

Droprise has been a Flyability reseller and partner since 2019, and has seen the evolution of the Elios drone from Elios 1, to 2, to the flagship Elios 3 in 2022. They specialize in providing drone inspection and surveying services construction and inspection projects, and operate out of Bruges, Belgium.

They wanted to pitch the Elios 3 with its Surveying Payload to potential clients but were faced with a problem. In the past, they have found that their local market has a strong desire to see the return on investment or impact of technology before adopting it. For this reason, Droprise needed to test the Surveying Payload in an environment that would prove its value to its potential clients.

The bridge survey was completed with the Elios 3 Surveying Payload

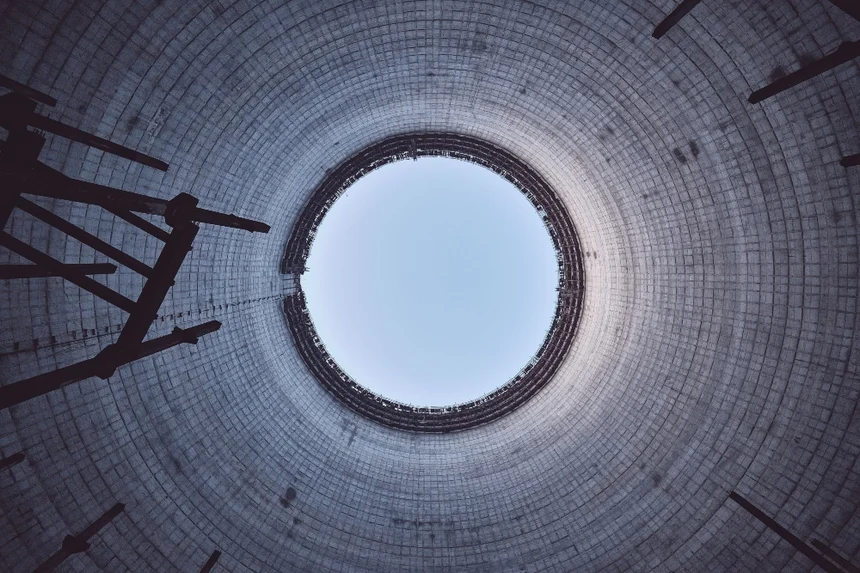

A team of pilots from Droprise and Flyability obtained permission to inspect key elements around a bridge for a busy section of the motorway. They did not have the right to fly over the bridge (as that could distract traffic), but they aimed to create a 3D model based on data collection underneath and alongside the structure.

Methodology for drone mapping a roadway bridge

A bridge survey with the Elios 3 would showcase its data quality and versatility of application in terms of both indoor and outdoor surveying. The Elios 3 flies without GPS, but uses the visual camera (VIO) and LiDAR stabilization to guide itself. It is also compatible with Remote ID, which is critical in some global markets, including the US. Because the Elios 3 does not use GPS, it does not risk losing GPS signal in-flight and thus can fly close to or underneath a bridge where other drones would lose GPS connection. As a result, this project highlights the value of the Elios 3 through its clear results and expanded capabilities.

As the traffic would not be stopped for this project, Droprise and Flyability had to ensure they piloted the drone in a way that would not distract and potentially endanger any drivers. This involved flying at specific angles of height compared to the road and not directly above. This bridge is a large structure, with enough complex features and the size to prove the efficacy of the Surveying Payload, as well as prove to potential Droprise clients in Belgium that the drone has a real value in the area - especially with a growing need for bridge or similar infrastructure inspections.

This bridge was built in 2014 and is partly over water that ships move through on a daily basis. There are no expected structural issues for such a new bridge, but it would never be possible to access the underside for inspection without constructing special scaffolding above the water, making it the ideal demonstration site for the Elios 3. The Elios drone made it easy to gain access without causing disruption, which is an ideal way of increasing the number of road bridge surveys without creating a complex project.

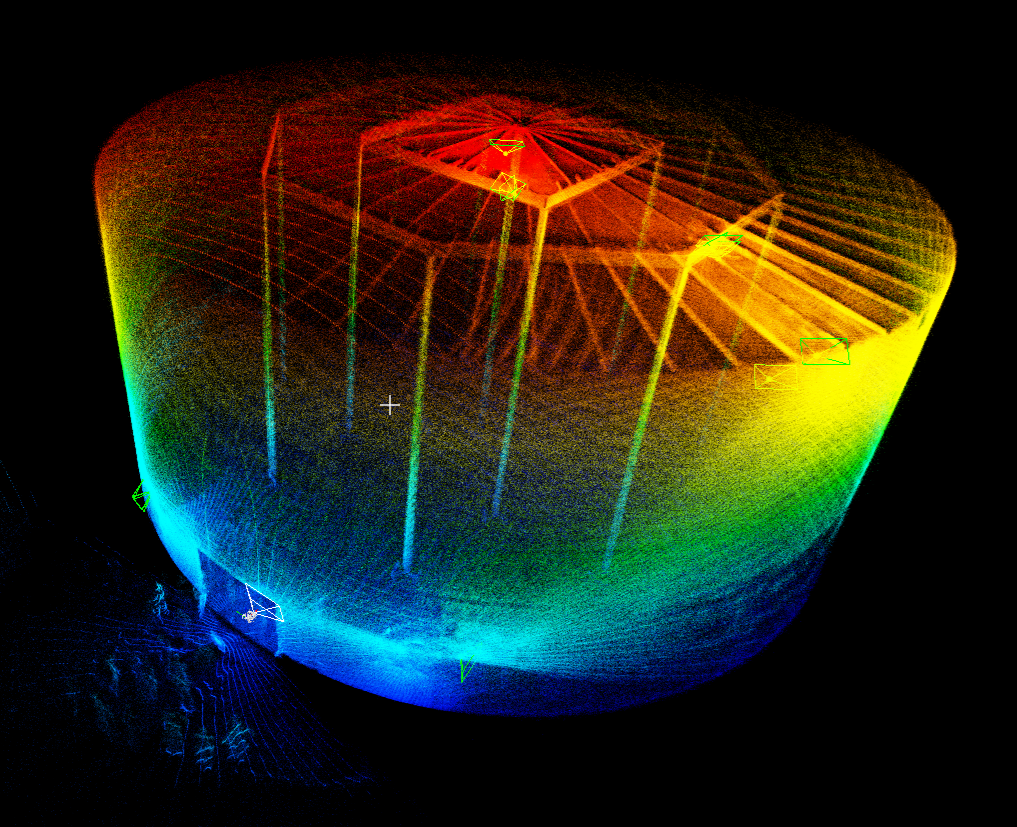

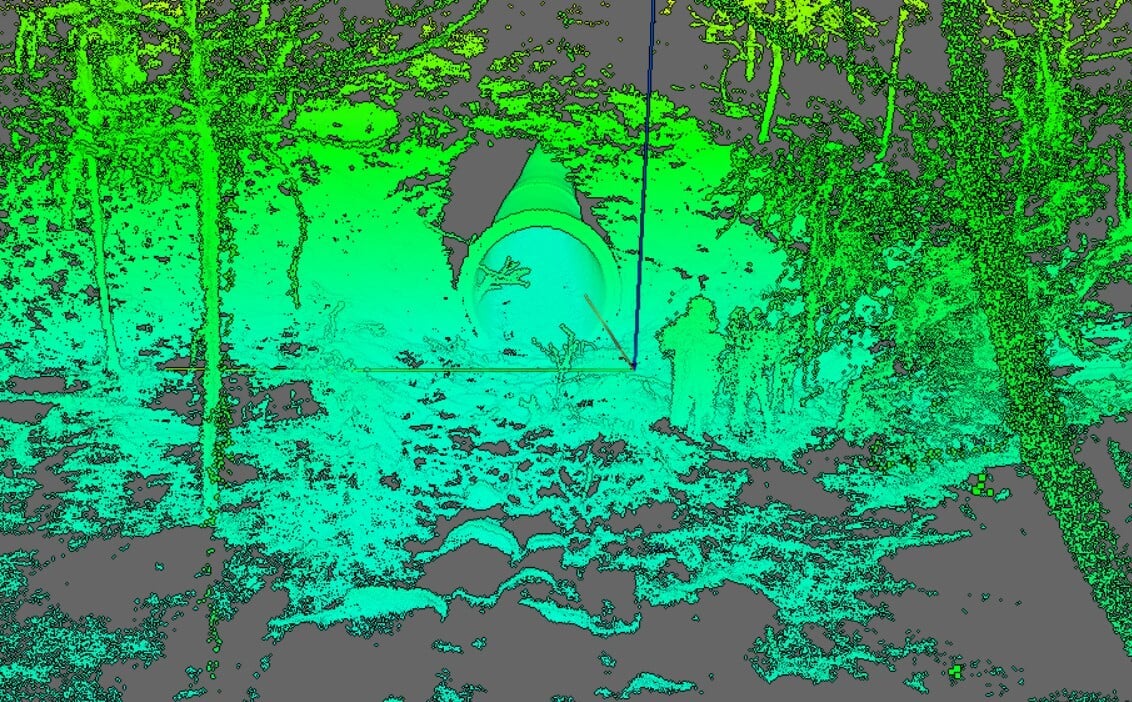

The amazing LiDAR results are shown with clarity in this video

The area being surveyed is 600 meters long and was inspected from multiple angles with just 4 flights. The pilot was careful not to cross the highway during the inspection while still flying close to the underside to gather all the necessary data. However, as the Rev 7 LiDAR records 1.5 million points per second, it results in a very dense point cloud. The team could see from the FlyAware live model that they were still capturing a comprehensive view of the bridge. The results were then processed with FARO Connect to align the multiple flights and recreate the bridge in 3D.

Results of road bridge survey with a drone

The amazing point cloud of the bridge produced with this flight shows great clarity and detail of the structure and provides a comprehensive view despite only collecting data from certain angles.

Droprise can now use this video to demonstrate the quality of data to their potential clients, with this example project being particularly relevant to major infrastructure management projects across the country. In the future, Droprise intends to do a follow-up flight that they will georeference to take advantage of the Surveying Payload’s heightened accuracy and FARO Connect’s automated georeferencing to streamline the digitization process and create a centimeter-accurate, localized model of the bridge.

-1.png)