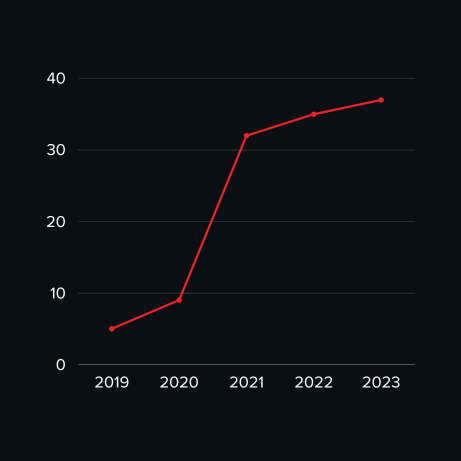

Up to $100K

cost avoidance each year per plant

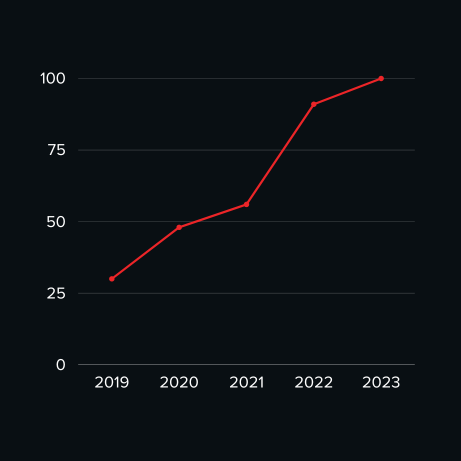

< 5 hours

for a preheader tower inspection

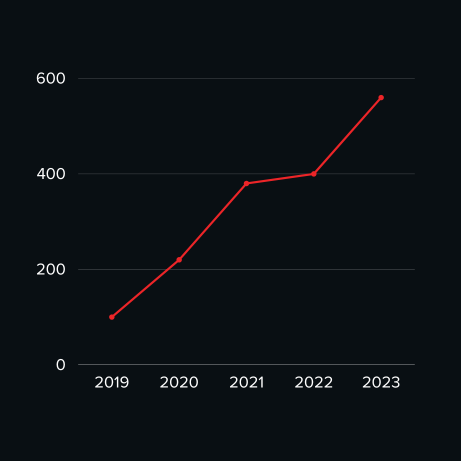

No human entry

in confined spaces

Holcim & Flyability: A History Of Collaboration

Holcim is a global leader in innovative and sustainable building solutions and the "Plants of Tomorrow" initiative demonstrates their strong commitment towards these goals. One of the main aims of this initiative is to accelerate the adoption of new technologies and solutions across the entire value chain and the collaboration between Flyability and Holcim is a good representation of this commitment.

By implementing drones in their plants, Holcim aims to improve the safety and health of their workers, while also improving the efficiency of their inspections and the conditions of their assets. Since 2018, Flyability has become a key technology provider for Holcim.

Testimonials

What People At Holcim Think About Elios Drones

Holcim US

Cody Boche

Holcim US

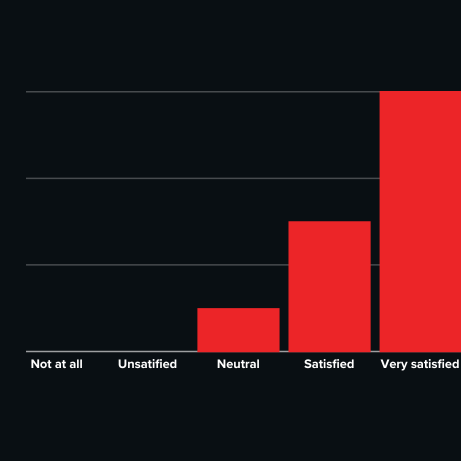

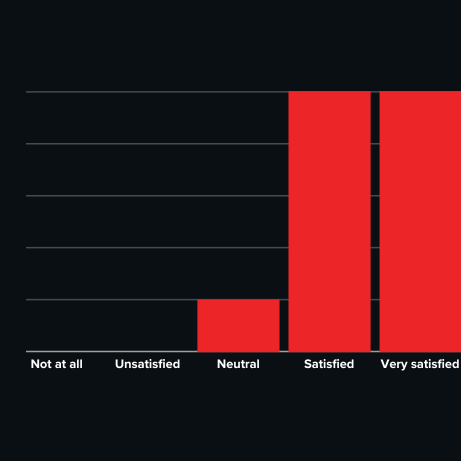

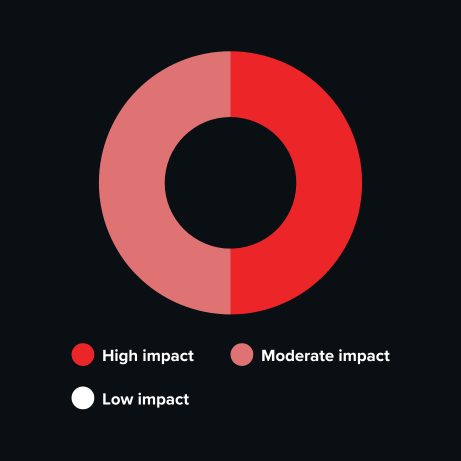

SURVEY RESULTS

What Drone Pilots At Holcim Think About Elios Drones

Locations

Holcim Plants Equipped With Flyability Elios Drones

Savings Calculator

Estimate How Much Money And Time You Can Save With Elios

Get In Touch

learn more

Discover Elios In The Cement Industry

.jpg?width=2000&height=1334&name=20230320_Holcim%20-%209%20(1).jpg)

| Safety | Preventive maintenance | Cost efficiency |

| Check the integrity of the structure before sending in humans. | Identify cracks during quick shutdowns & plan for appropriate maintenance. | Proceed with small repairs before the issues get bigger. |

After cleaning operations, use a drone to spot potential structural issues and plan for appropriate maintenance. Look for signs of corrosion cracking or peeling in the rooftop coating. Inspect the walls to detect buildups that could indicate asymmetric flow and/or represent a danger for people entering later with rope access.

| Safety | Speed | Cost efficiency |

| No confined space entry | 15 min inspection process | +80% cost reduction vs. traditional methods (from reducing downtime) |

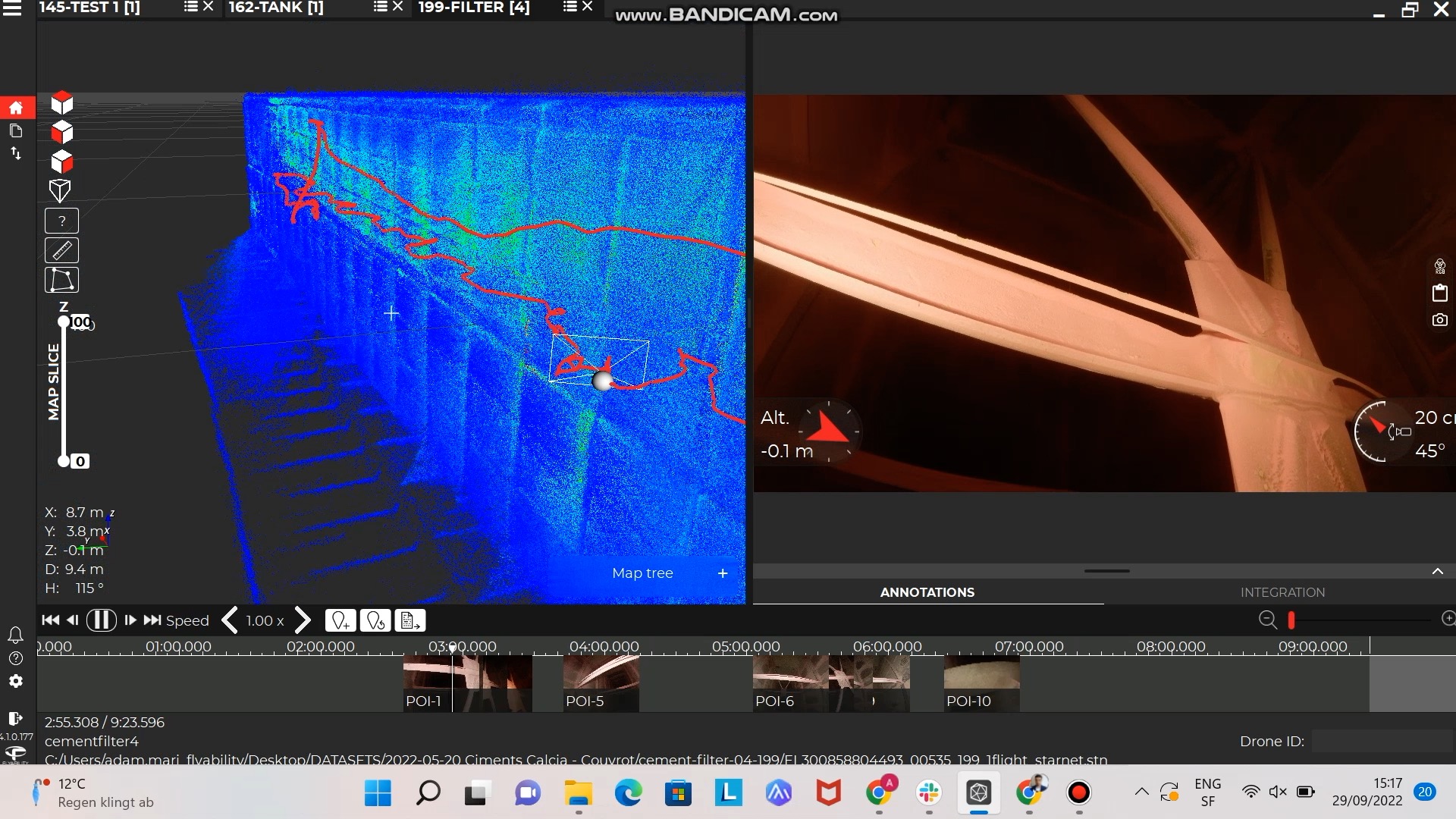

Quickly deploy a drone inside a cement filter to locate defects and rapidly plan for repairs.

Once a mission is complete, import the data collected into Inspector 4, our companion software, and start analyzing your flight一frame by frame.

| Safety | Speed | Cost efficiency |

| No human entry | Data captured with the Elios 3 in only one flight (<9min) | 2h downtime vs 2 full days using the traditional inspection methods |

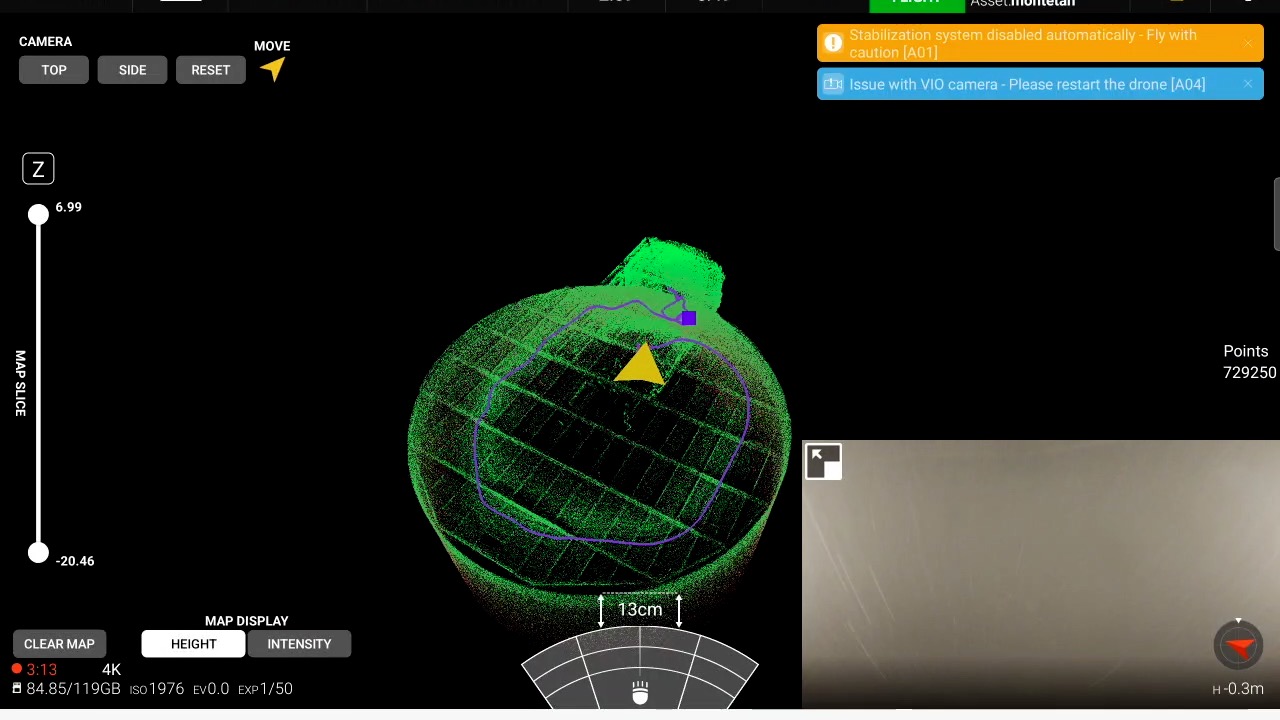

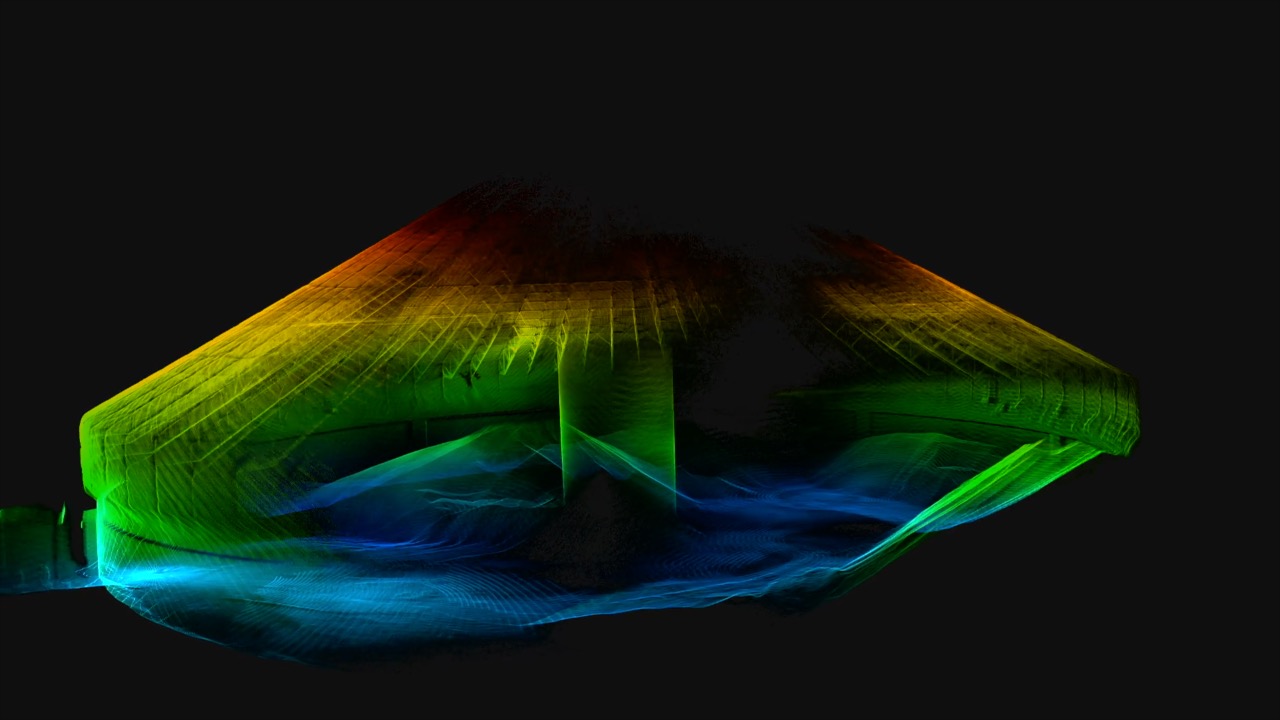

Use Elios 3 LiDAR data to map indoor stockpiles in only one flight ensuring efficient and compliant stock management—even in the biggest silos.

| Safety | Speed | Accuracy |

| No work at height | 9 minutes data collection process | Highly accurate volume measurement |

Assess the general condition of a cyclone and take note of wear areas, damages, indications of loose material, and air leaks. Thanks to the 3D Live Map, ensure you get full coverage inside the asset.

| Safety | Speed | Cost efficiency |

|

No human entry. Visual inspections are performed remotely, from a safe distance |

4h inspection process |

+90% cost reduction vs traditional methods (from eliminating scaffolding) |

Quickly identify cracks, missing bricks, and other defects on the inside of a tall-high chimney. Use 3D LiDAR data to precisely locate the anomalies and monitor their evolution over time.

| Safety | Speed | Cost efficiency |

| No human entry. | <1h for a visual inspection | +90% cost reduction vs. traditional methods (from labor cost) |

Latest news

News | Flyability & Holcim

News | Flyability & Holcim

News | Flyability & Holcim

.jpg?width=279&height=270&name=Migo%20(1).jpg)