- Blog >

- What is an Ore Pass in Mining?

What is an Ore Pass in Mining?

An ore pass is a mining shaft used to transfer ore and mining waste from the mine. Ore passes are a convenient way to transport and handle materials and minimize hauling distances between levels in a mine.

Considerations for Building an Ore Pass

Ore passes take advantage of gravity to move materials from one level of a mine to another. There are two methods for developing an ore pass: the drill and blast method and the mechanical method.

The drill and blast method requires miners to drill a hole in the location of the ore pass to then place explosives, blasting a hole for the ore pass. The mechanical method involves using a raise borer, which excavates a circular hole between mine levels.

When building an ore pass, miners consider the following:

-

Location. Ore passes should intersect mining levels, making it easy for miners to access hang-ups, or blockages, within the system. Ore pass hang-ups are a common problem in underground mining. Stress conditions and rock type should also be considered when choosing a location. If the ore pass is placed in a location with weak host rock, then the ore pass may be more prone to hang-ups. Ore passes should be located at the opposite end from the mining face in order to maintain the structural integrity of the mine.

-

Length. Longer ore passes are more susceptible to degradation and are more costly to build. Typically short ore passes ranging from 10 to 100 meters will be built in mines, but some underground passes can run as long as 300 meters.

-

Dimension. Ore pass dimensions are directly influenced by the shape of the opening and the size of materials that will pass through the underground passes.

-

Shape. Ore passes can be square, rectangular, or circular. Underground passes that are created using a raise borer are circular.

-

Orientation. Ore passes are either vertical or set on an incline depending on the mine layout, the materials, and the material fragmentation. Vertical ore passes tend to cause more damage to the walls of an ore pass.

-

Support. Ore passes can be supported by rebar and liners, like shotcrete.

Watch this video to see footage from Flyability's Elios drone shot inside an ore pass with a hang-up obstructing it:

Types of Ore Pass Systems

There are two types of ore pass systems in the mining industry: a flow-through ore pass system and a full ore pass system.

For both systems ore and waste is dumped into the ore pass and ends up at the draw point, or point in which the ore is transported by a loader, conveyor, or rail car to an underground stockpile.

Flow-Through Ore Pass System

In flow-through systems, ore is dumped into the ore pass and then flows down to the draw point.

This system is used when ore has high levels of fines, or fine particulate, that results in ore pass hang-ups. Because material is flowing at a continual rate, fines don’t settle and hang-ups are less likely to occur.

Flow-through systems are also used when broken rock is passed through mills—a device that breaks up the ore into smaller pieces—at a rate that exceeds underground ore production in a full system.

Because of the near constant flow of broken rock through this system, the ore pass is more susceptible to damage that may require reinforcements, maintenance, or even a costly redesign that could prolong downtimes in the mine.

Full Ore Pass System

In full ore pass systems, a certain amount of ore is maintained in the ore pass at all times.

This system is used to prevent degradation of the ore pass, to prevent rock failures, and to prevent mining-related seismic events. However, there is an increased risk of ore pass hang-ups in this system since rock is not consistently flowing through the ore pass. Because of this, fines settle in the underground pass and oxidize, causing these blockages.

In a full ore pass system, the mill is continually fed, making it difficult to maintain overflowing material levels. By increasing draw times from the ore pass, these levels can be better maintained.

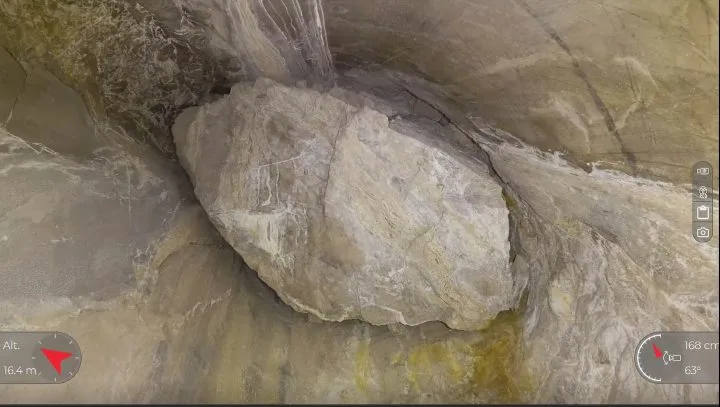

A hang-up in an ore pass

A hang-up in an ore pass

Ore Pass Monitoring

It’s important to monitor the ore pass in order to preserve the ore pass’s structural integrity, to prevent mining related seismic events, and to prevent overfilling of the ore pass.

Monitoring the material level in an ore pass

The following are monitored and inspected, either manually or by a mine drone, in an underground ore pass:

- Material levels

- Wall quality

- Liner quality

- Material control equipment

Regular ore pass monitoring and inspections can prevent hang-ups and keep the mine safe. Failure to monitor an ore pass could lead to unwanted runs of ore and hang-ups. This can cause equipment damage or failure, can threaten underground structural integrity, and can even cause injuries or fatalities to miners.

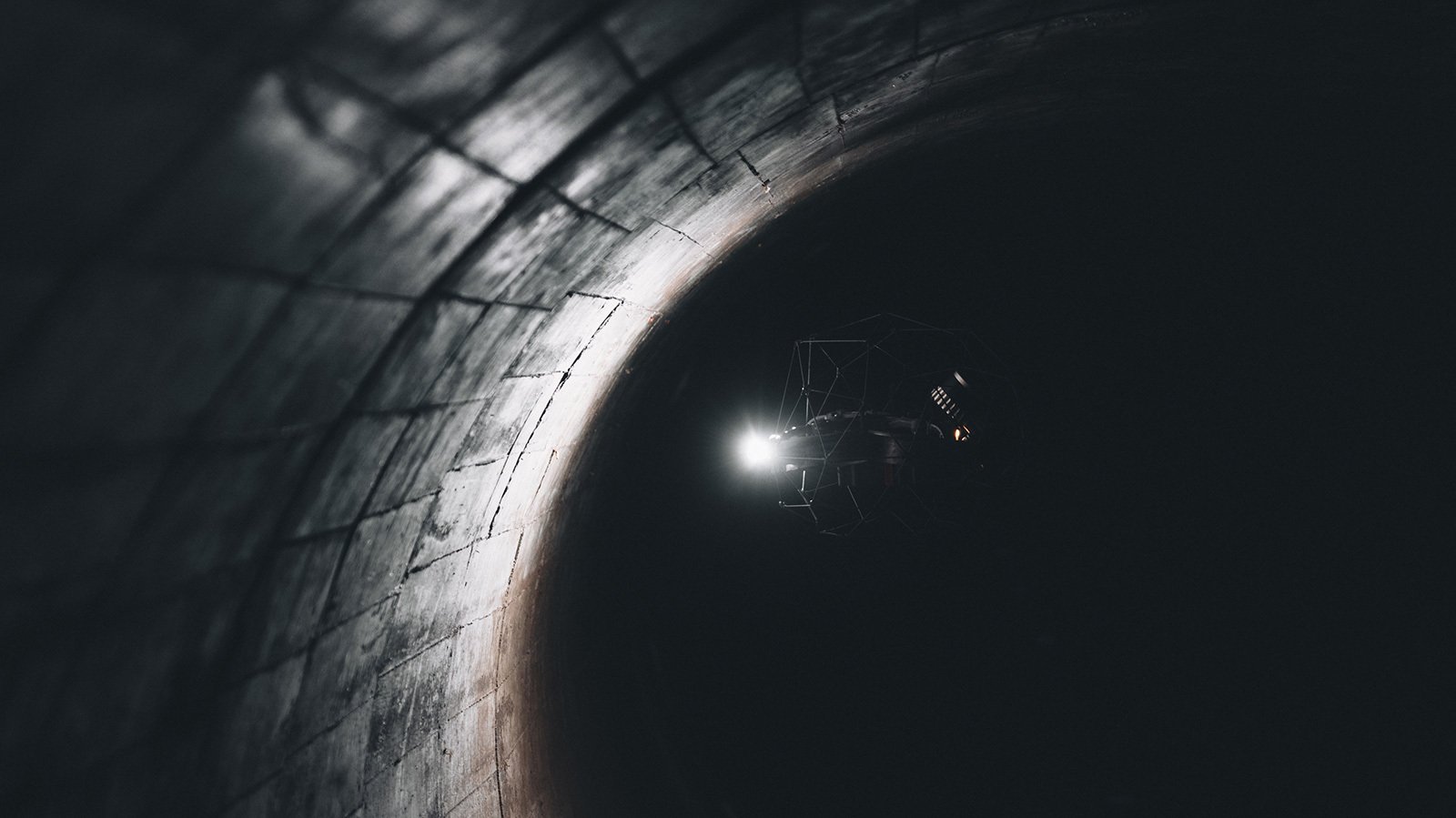

Using drones to investigate ore pass blockages

A blockage, or hang up, in an ore pass can bring operations in a mine grinding to a halt. In 2023, personnel at a major mining operation in Colorado encountered a large hangup in an ore pass that was so big it was preventing any ore from falling down the pass.

Often, these kinds of clogs are found quite close to the truck chutes—the place where the ore exits the raise and is collected by trucks for transportation to be crushed. But after looking up the raise, personnel in the mine couldn’t see anything in the truck chute. This meant the clog was located somewhere out of sight, farther up the raise.

To find the clog, personnel started by feeding a CMS scanner into the raise through a small access hole in the chute.

The scanner’s data provided a low density point cloud of the raise, and they could see that the general location of the hangup was about 27.5 meters (90 feet) up the raise. Using this information, they began drilling exploratory holes of 12 to 21 meters (40 to 70 feet) long from a higher production level into the ore pass and then feeding a sewer camera (a small, finger-diameter camera) into them, trying to find the exact location and nature of the clog.

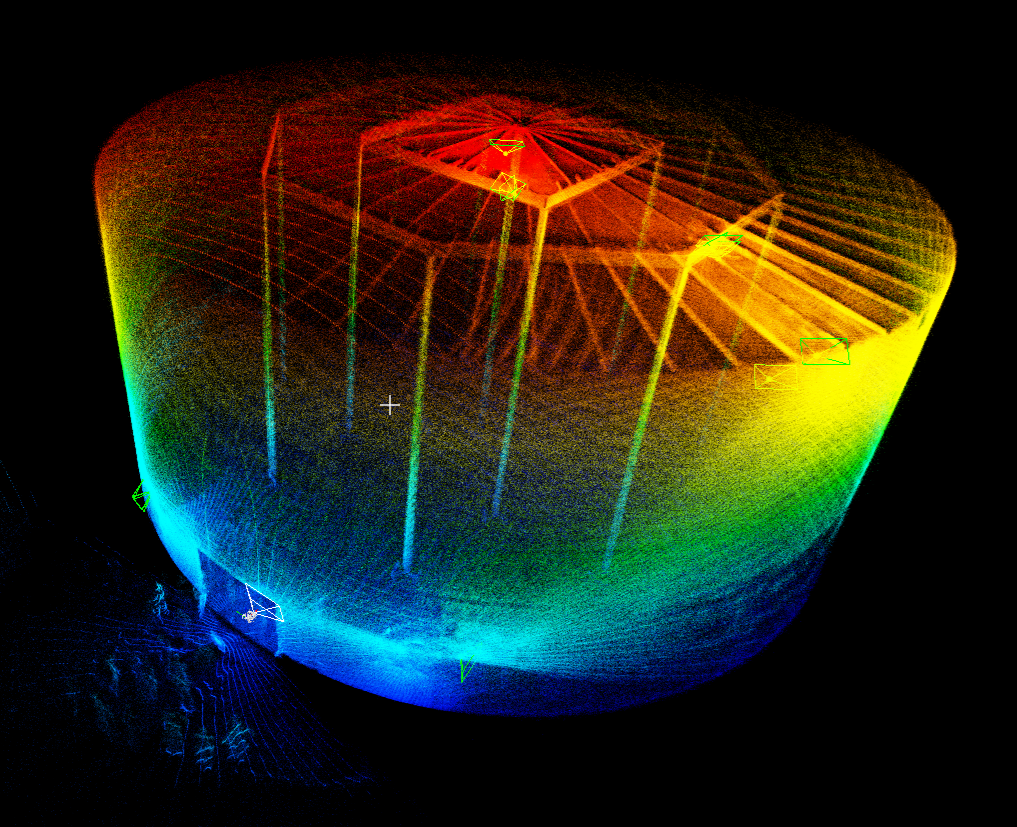

A CMS scan from an access hole in the chute

A CMS scan from an access hole in the chute

After finding the mass in the ore pass with the CMS scans, they believed they could try to clear it. But despite repeatedly drilling holes into where the hangup was believed to be, dropping small charges into it, and getting small bits of jumbled material to fall out of the bottom of the truck chute, the raise remained clogged. For two months these attempts to clear the hangup went on, with no success.

After two months, the area of the mine where the clogged raise was located became exhausted and upper management decided to stop working it. This meant that the clogged ore pass system was no longer needed, and the area was abandoned without ever truly understanding where the clog was or what it looked like.

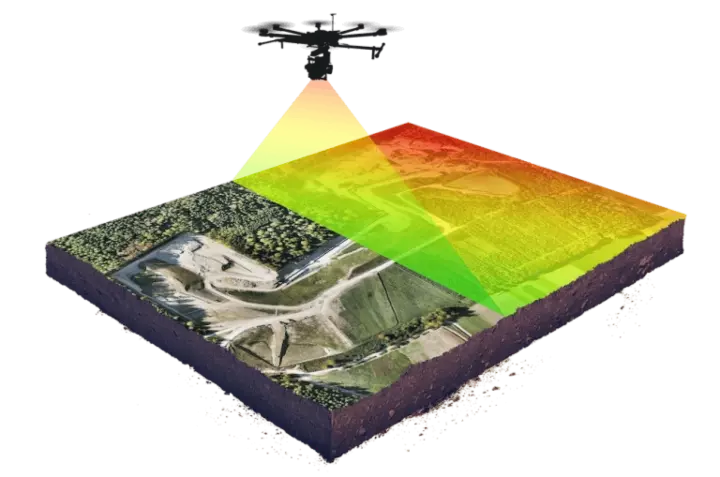

The solution was to use the Elios 3, an effective drone for mining.

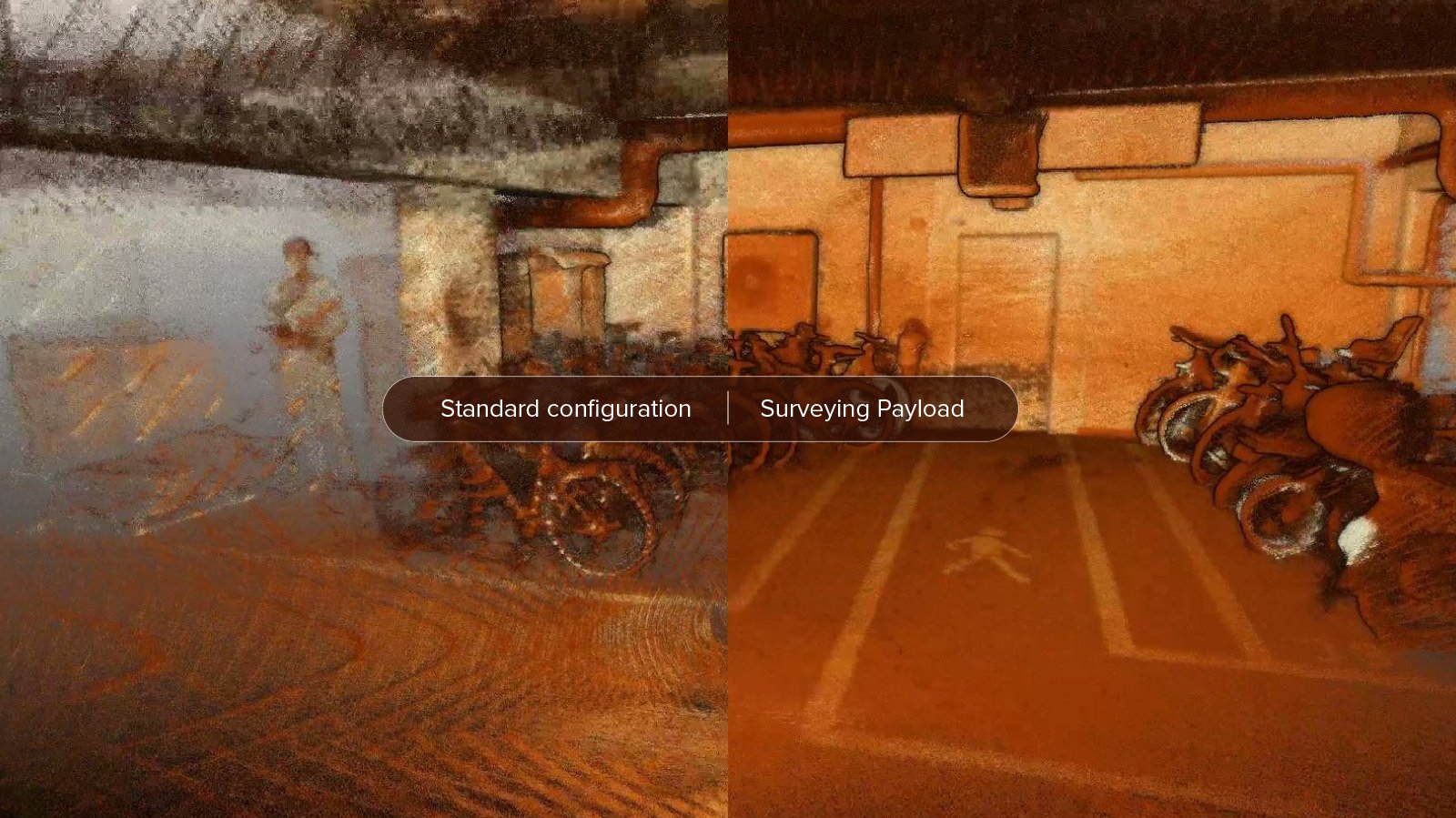

The Elios 3 provides pilots with both a live visual feed and a 3D Live Model on their tablets, allowing them to see what the drone is seeing visually and to see what the surrounding environment looks like in a 3D model, at the same time.

Because of these two features, mine personnel believed that the Elios 3 might be the perfect solution for understanding the location and nature of the hangup.

Within ten minutes, geolocational data on the Elios 3’s 3D Live Map showed them exactly where the clog was located in the raise.

You can learn more about how they used the data from the Elios 3 survey to investigate and deal with the ore pass hangup.