- Blog >

- What Is Scaffolding?

What Is Scaffolding?

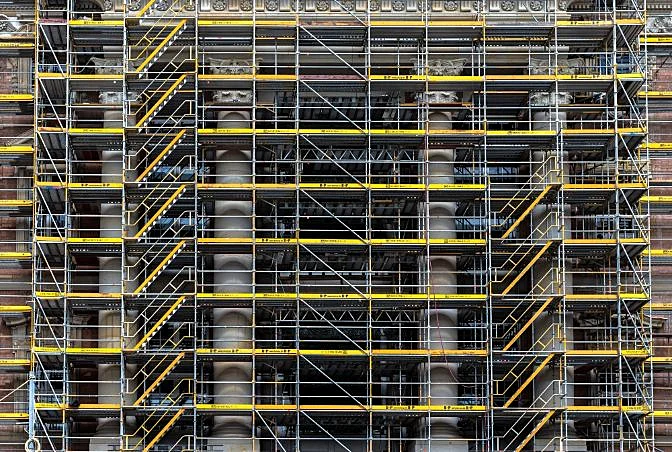

Scaffolding is a temporary structure that is typically made from metal poles and wood planks and used to support construction workers, inspectors, cleaners, and others who need to work at height.

[Note: This article is about scaffolding as it relates to industrial work. If you’re interested in learning about scaffolding as it relates to education, we recommend reading this article from Grand Canyon University.]

The use of scaffolding dates as far back as the stone age—in fact, there’s evidence that scaffolding was used over 17,000 years ago by those who made the famous paleolithic cave paintings at Lascaux.

Scaffolding has been used in ancient populations from across the world, with documented cases including ancient China and Egpyt where rudimentary scaffolds were made of wood and tied at the top with ropes.

In the modern age, scaffolding has developed far beyond these early versions, and now comes in several different designs made from several different types of materials.

This article will cover how scaffolding is currently used, its types and parts, how to make it, navigating rental versus purchasing, and close out with a look at how new drone technology is helping workers across various industries significantly reduce their need for it.

What Is Scaffolding?

A scaffold, also called scaffolding or staging, is a temporary structure that allows people to stand on a stable platform for work at height or in hard-to-reach places.

These temporary structures are often used in constructing, maintaining, or repairing buildings, bridges, and other man-made structures by supporting work crews and materials.

The Benefits of Scaffolding

There’s a reason scaffolding has been used for thousands of years—it works. To this day, scaffolding remains one of the most useful and efficient ways for people to work at height.

Here are the primary advantages to using scaffolds for work at height:

-

Access. Scaffolding can allow unhindered, stable access to almost any area of a structure

-

Balance. Scaffolds put workers on a firm footing, giving them the ability to balance themselves in different positions while working.

-

Ease of construction. Scaffolding is relatively easy to assemble and disassemble, and can be put up and taken down fairly fast.

-

Long-lasting. Most scaffolds can last for a very long time, whether they’re made from wood or from steel.

-

Safety. Safety is one of the most significant advantages of scaffolding, since it gives workers a stable platform for their work. That being said, the ideal solution for work at heigh is to reduce or even remove the need for a person to be present—in the last section of this guide, we’ll cover how drones can help inspectors reduce their need to work at height.

-

Serves as a bridge. A number of construction activities require workers to take long and winding routes to reach certain locations on the job site, which is an enormous waste of time. Bridging points in scaffolding can help solve this problem by reducing the distance that workers have to travel.

The Dangers of Working on Scaffolding

Any time a person has to work at height there is a risk associated with the work, and work on temporary structures like scaffolding is no different.

According to OSHA (the U.S. Occupational Safety and Health Administration):

-

Scaffold-related accidents cause about 4,500 injuries and 60 deaths in the U.S. each year.

-

Falls from scaffolding account for approximately 25% of all workplace fatalities.

-

Almost 72% of those injured attributed their accident to the planking or support giving way, to slipping, or to being struck by a falling object.

-

The most common safety violation on construction sites is inadequate fall protection training.

This data is just for the U.S. Extrapolating from these numbers to estimate global data, we can see that there are probably hundreds of deaths and tens of thousands of injuries related to work on scaffolding around the world every single year.

Given how common work on scaffolding is, the injury rate is not alarmingly high. But it is worth noting that scaffolding work carries inherent risks, and that, if you can avoid that work, you will improve safety for workers

Wondering what the most common dangers are associated with work on scaffolds?

Here are the most common:

-

Defects. Scaffolding-related accidents are often caused by faulty scaffolding. Some examples of defects include compromised steel tubing is compromised or screws not lining up as they should.

-

Falling objects. Falling objects like tools, construction materials, or debris are a common cause of injury for those working on staging. To avoid injuries associated with falling objects, a best practice is to provide a cover for each level of scaffolding.

-

Weather. It can be extremely dangerous to work at height on a partially-constructed building when the weather is changing. Rain or snow can make the planking slippery, and temperature fluctuations can compromise attachment points and cause planks to loosen, crack, and fail.

-

Ignoring safety standards. Numerous other factors can lead to serious and fatal accidents, including overloading scaffolding and placing scaffolding too close to hazardous energy sources.

-

Inadequate training. Work on scaffolding and constructing scaffolding both call for specialized training. Scaffold builders and erectors must be trained in scaffolding construction and safety standards for the particular scaffolding they are erecting, and scaffold workers must be knowledgeable about the risks associated with scaffolding.

-

Inadequate or weak planking. Scaffolding for all types of work must have sturdy planking for worker safety. Fall risks can result from weakened or inadequate scaffolding supports, posts, mast climbers, pump jacks, and other mechanisms.

-

Inexperience, incompetence, and negligence. It’s extremely dangerous to work on a construction site with individuals who lack training or experience, or don’t take safety risks seriously. The negligence of coworkers can be especially dangerous when scaffolding is involved.

-

Insufficient supply of safety equipment. It is still necessary to provide workers with access to appropriate safety equipment even when scaffolds are designed, manufactured, and constructed properly.

-

Poor construction. Accidents on construction sites are often caused by improper scaffolding construction, which includes failing to attach all attachment points properly, failure to install bracing, or failure to install guardrails.

-

Poor maintenance. To remain structurally sound scaffolding needs to be properly maintained. Old materials can wear out with time, and slippery surfaces and other safety hazards can also occur as a result of inadequate maintenance.

Uses of Scaffolding

Scaffolding is used for a variety of activities these days. Here are some of the most common uses of scaffolding:

Cleaning

Workers commonly can stand on scaffolding to clean windows and other parts of skyrise buildings.

Construction

Scaffolding can be crucial for construction, since it allows workers to stand at height on a stable surface. This is especially true for skyscrapers and other high rise structures, but its use is also common for construction work done closer to the ground.

Industrial inspections

Inspections are one of the top uses of scaffolding, since scaffolding allows inspectors to reach areas they couldn’t otherwise access in order to perform visual inspections or other kinds of NDT testing.

Inspectors commonly use internal scaffolding or other temporary structures for internal inspections, like those performed inside huge industrial boilers or pressure vessels, as well as for external inspections. Regardless of the specific inspection, the use of the scaffolding is the same—it allows inspectors to stand at height and conduct various types of testing in order to satisfy inspection requirements.

Maintenance

Inspections are typically the first step in a maintenance process, since they uncover areas that may require maintenance. After inspectors find these areas, maintenance workers will address those defects by standing on scaffolding to perform their work.

Other uses

Various types of scaffolding are also used in:

-

Art installations

-

Concert stages

-

Exhibition stands

-

Grandstand seating

-

Observation towers

-

Shoring

-

Ski ramps

Alternatives to scaffolding: using inspection drones

We have already seen that there are downsides to relying on scaffolding, from risks of work at height to dropping equipment, as well as how it can be slow to erect and dismantle. There are some alternative means of access, depending on the project. For instance, in some maintenance cases, it can be easier to use rope access instead of scaffolding as this is more adaptable and targeted.

For industrial inspections, including visual surveys and non-destructive testing, drones are proving to be a viable alternative to scaffolding. Drone inspections present a way for inspectors to collect the data they need remotely, without having to put themselves in danger.

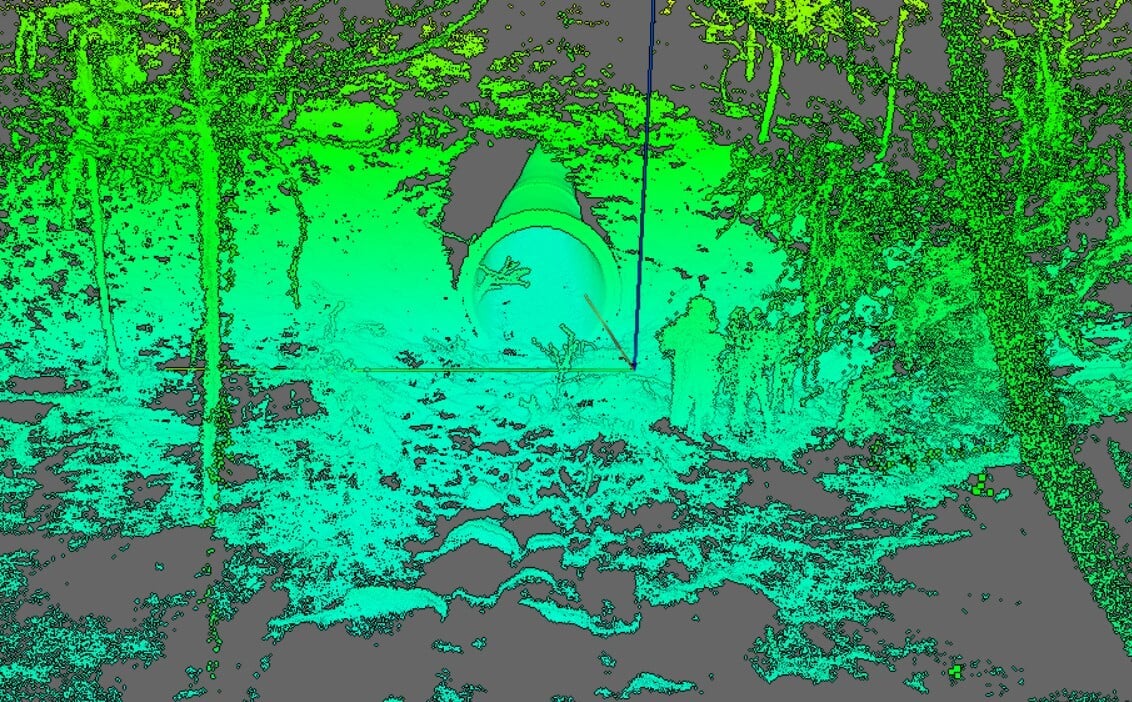

Drones like Flyability's Elios 3 (shown above) can fly up to locations at height to collect high-quality visual data, allowing inspectors to reduce or even fully eliminate the need to work on scaffolding or on ropes. These drones can also be adapted - some have modular payload designs that help them carry different sensors according to the project at hand, from ultrasonic thickness gauges to radiation dosimeters.

Here are some of the primary reasons inspectors are turning to drones as a replacement for the need to work on internal scaffolding:

-

Safety. Because drones can collect visual data remotely, inspectors don’t have to place themselves in danger by working at height on scaffolding to collect that data.

-

Savings. The cost of putting up and taking down temporary structures like scaffolding for inspections can be incredibly high, sometimes costing tens of thousands or even hundreds of thousands of dollars. The need for scaffolding for inspection work can be significantly reduced using drones, which represents significant cost savings for companies.

-

Reduced downtimes. Because scaffolding takes so long to erect and take down it can significantly extend the downtime for an asset, leading to further expenses for a company. By reducing or even removing the need for scaffolding for inspections, drones can significantly increase savings for companies.

-

Speed. Drones can collect visual data more quickly than an inspector conducting a manual inspection, further improving the efficiency of the inspection process.