- Blog >

- What is Stockpile Measurement?

What is Stockpile Measurement?

Stockpile measurement is a technique used to determine the size, volume, or weight of a commodity stockpile. Frequent stockpile measurements are used to track changes to stock in order to order new material, calculate inventories, as well as plan future industrial processes.

Businesses dealing with materials in bulk inevitably amass stockpiles of goods, usually found at dedicated storage facilities built for housing bulk materials. These piles are dumped by trucks, pushed by bulldozers and moved around by workers. So how do managers and workers know what they actually have?

In the past, workers have had to guess or estimate the exact size of a commodity stockpile using manual methods and GPS services that were only accurate within a certain range.

However, with new innovations in stockpile calculation techniques, companies of all kinds can now take hyper-accurate stockpile measurement, increasing productivity and cutting costs across the board.

Sulfur stockpile

Sulfur stockpile

Why Is Stockpile Measurement Important?

Accurately measuring stockpile volume can benefit companies across a wide range of industries. Whether you’re working with coal, ores, fertilizers, or industrial dust, stockpile volume calculation can help you cut costs and run a more efficient business.

Here are just a few of the reasons why stockpile measurement is important:

It Is More Profitable and Efficient

If workers are only estimating or guessing the amount of product within any given stockpile, it’s inevitable that some materials are going to go to waste. Traditional methods of stockpile measurement can only go so far, and for every pound of product that is not accurately measured, profits may be lost.

With stockpile measurement solutions, businesses can reduce excess inventory and the costs associated with it.

Stockpile calculations can help save money in other areas of a business as well. Accurate stockpile measurements can help companies know when to make new orders or when to begin mining again.

This allows businesses to plan for machine downtime and better organize workers and contractors, which saves money on maintenance, repairs, and salary.

Accurate stockpile volumetry also allows a company to be more efficient in their strategic decision making. In most cases, this results in increased productivity and higher profits. This is why the ROI in upgrading one’s stockpile measurement tools is worth it.

It Gives You Data You Can Use

If gathered correctly with the cutting-edge technology now available, raw stockpile measurement data can be used to help businesses in a number of different ways.

We’ve already seen how stockpile calculations can help increase profits and productivity internally, but stockpile measurements can also help companies save on taxes and qualify for loans and other financial assistance.

The more accurate a business’s stockpile measurements are, the more readily and easily they will be able to use that data and show it to external organizations.

Using stockpile volume calculation techniques, companies can properly and transparently evaluate their inventory for financial reports and other excise duties. Businesses can also use this data to apply for loans from banks and other financial situations.

In short, the more accurate data you have about your stockpile volume the easier it is to actually use that data to your benefit.

It Helps Companies Follow Regulatory Requirements

Stockpile measurements can also help businesses that need to meet certain regulatory requirements.

For example, the EU Emissions Trading System requires businesses to do a mass balance to calculate their CO2 emissions, a task that is made much easier by accurate stockpile management.

The key here is not just accuracy but transparency as well. If national regulators or other compliance boards see that a company’s stockpile data has been measured to the inch, they can rest well knowing that the data has not been altered or estimated in any way.

In this way, stockpile volumetry helps both the business and the regulatory board do their work quickly and efficiently.

It Helps Prevent Workplace Injury

Stockpile measurement can ensure that workers are not put in dangerous or hazardous situations.

Accurate stockpile measurements help ensure the transport and management of the bulk storage material is being properly managed. When it is time to transport the material, the team involved can use the correct safety standards in line with the volume they are managing.

In addition, stockpile measurement and tracking help prevent collapses or slips. If a stockpile is unstable, the material can move unexpectedly. Having a clear understanding of the condition of the stockpile helps site managers prevent accidents and transport material in good time.

Cutting-edge stockpile measurement technologies like drones have replaced traditional stockpile volume measurement tools across a number of industries, which places another barrier of protection between workers and materials that may be dangerous or hazardous.

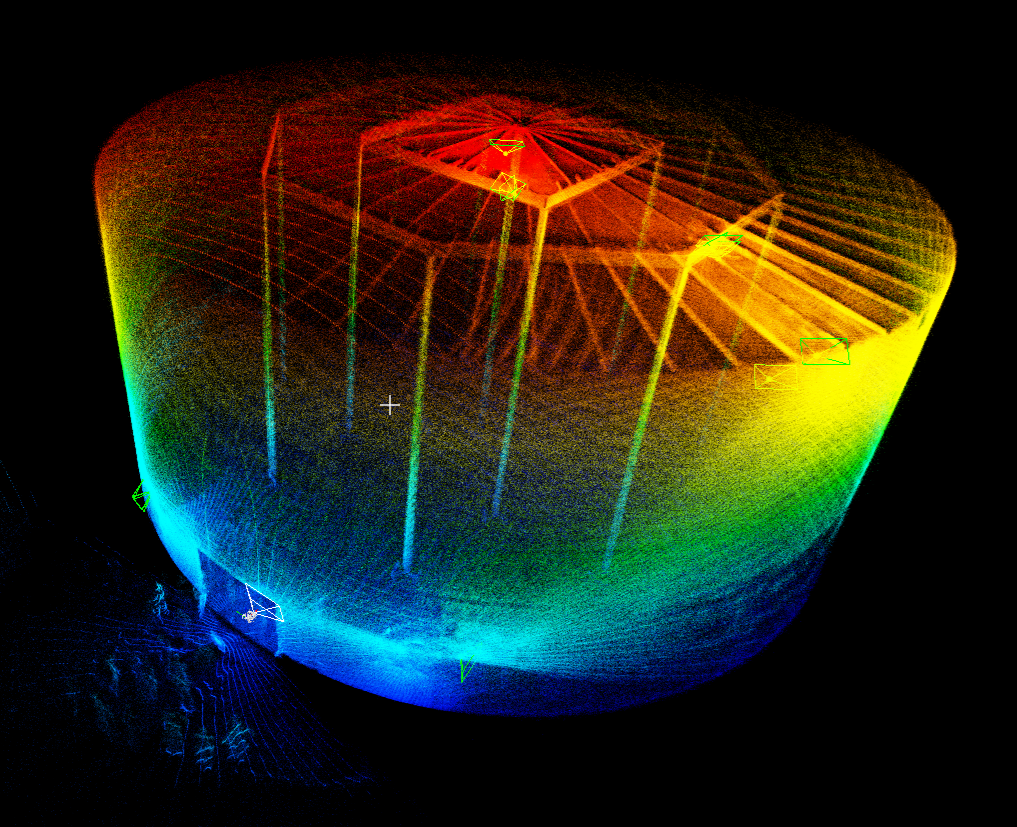

Below is a 3D fly through of stockpiles of salt at a salt mine. The fly through was made as part of stockpile measurements made with LiDAR data collected by the Elios 3—read the case study to learn more.

Enormous stockpiles of dust, stone, or fertilizer can be unpredictable for a human worker to walk across or manually measure, sometimes containing treacherous air pockets that workers can fall into. However, with a UAV or other robotic measurement tool, there is virtually no risk at all.

Lastly, since proper stockpile management can reduce downtime and maintenance costs, workers are less likely to put themselves in dangerous positions for repairs in a business where proper stockpile volume calculation methods are in place.

Which Industries Use Measure Stockpiles?

The following industries use stockpile measurement:

Aggregates

An aggregate is a construction material made up of raw materials that are extracted from natural sources and quarries—like sand, gravel, and crushed stone.

When these small pieces of rock are combined with a binding agent—like water, asphalt, or cement—they are turned into different types of concrete, which is in everything from roads to bridges to parking lots.

Because most aggregates contain a number of elements that are fine, loose, and variable in size, stockpile management of aggregates can be incredibly difficult.

Stockpile aggregates

Not only are the many different pieces of aggregate different to measure as a cohesive group, but different projects regularly call for different mixes, meaning that manufacturers and suppliers need to measure and maintain different stockpiles of different aggregate mixes at the same time.

Stockpile measurement of aggregates not only helps workers use materials efficiently, but it also helps to ensure that different aggregate mixes are not cross-segregated and that stockpiles of different materials do not mix.

Aggregate stockpile measurement is vital to stockpile maintenance as well—having accurate data about materials allows builders and workers to protect their inventory against things like water damage, erosion, and other types of degradation.

Construction

Other types of construction businesses also employ stockpile measurement solutions. Construction suppliers that deal in materials like sand, dirt, wood chips, paper chips, and other kinds of asphalt and concrete rely on daily stockpile calculations to manage inventory and assign workers.

In construction, the information gathered from stockpile volume calculation is also used to plan hauling routes both into and out of a construction site.

This is another area in which proper stockpile measurements can increase worker safety and satisfaction—dozer and crane drivers can know where they are going and exactly how much of a given material will be there before they even step foot in their vehicle.

Mining

Mining and ore management is one of the areas in which stockpile measurement solutions are most often utilized. Stockpile volumetry can be used to measure inventories of materials like iron ore and other minerals with up-to-the inch accuracy.

Additionally, stockpile measurement technology, like a mining drone, allows for increased safety at mining sites, as workers no longer have to manually measure inventory that may consist of sharp and jagged rock edges.

Quarry mine stockpiles

Quarry mine stockpiles

Mining sites are often vast and expansive, with some sites covering hundreds if not thousands of acres and consisting of dozens of different stockpiles.

With the amount of overburden that a mine produces, a large portion of mining operations is allocated to organizing these materials. However, with the right stockpile calculations, mining operations can radically increase both worker efficiency and worker safety.

Recycling

Another industry where it is vital to have accurate information on material stockpiles is in industrial recycling and waste management.

In one case study by Flyability, a company whose primary work was the recycling of industrial dust and related residue was able to use breakthrough stockpile measurement and drone technology to increase the accuracy of their inventory estimates by more than 200 percent.

Once this company knew how much inventory they had in their facility at any given moment, they were able to more accurately predict how long it would take those stockpiles to be recycled into something returnable and usable.

Additionally, the company was able to make sure that the stockpiles didn’t fall below or rise above capacity. They were also able to more easily comply with laws concerning the storage of stockpiles of various materials.

Shipping and Ports

There are few places in which commodity material stockpiles are more common than in ports and shipping centers. Whether it be the materials listed above—like aggregates, ore, dry-bulk chemicals, or agricultural products—stockpiles at shipyards and ports require constant supervision and management.

Stockpile measurement in shipping and ports

Stockpile measurement in shipping and ports

Stockpile measurement as it pertains to shipping and ports is not too different than it is in the other industries we have listed above—companies use it to chart hauling routes, save money, and lower the risk of workplace injury.

However, since these particular stock yards are in direct conversation with shipping routes and global supply chains, the importance of accurate measurements and data cannot be overstated.

Even the slightest variation in data can result in a loss of fuel, time, or money.

Stockpile Measurement Methods

Stockpile measurement data can be calculated using a number of different methods, all with variable amounts of accuracy and use cases. Below, we’ll explore some of the most common options, and we’ll also examine which types of situations and industries each method may be suited for.

Each of these stockpile measurement methods below (perhaps with the exception of some of the archaic traditional methods) measures stockpile volume in two steps:

-

Data collection. Information about the stockpile is collected by a sensor or collector. This can be done by a number of different devices: a LiDAR scanner, a camera, an iPhone, or even the human eye. It’s important to note that these devices merely collect the data. They do not perform the somewhat intricate mathematics required to calculate stockpile volume.

-

Data calculation. In this step, computers and complex algorithms take the data that was collected about the stockpile and perform calculations to determine the size, measurement, and volume of the stockpile. The speed of this step can be quite variable depending on the size of the stockpile, the number of data points, and the desired accuracy. Many stockpile measurement solutions companies offer same-day data calculations.

Now we can take a look at the different calculation methods used to measure stockpile volume.

Manually

Traditional, manual methods of stockpile measurement are the least accurate option. With new, inexpensive, and accurate options now on the market, manual stockpile calculation is now generally avoided.

That being said, if one must calculate the volume or size of a stockpile using manual methods, there are a number of different options to consider.

Traditional stockpile measurement with a walking wheel and tape measure

Traditional stockpile measurement with a walking wheel and tape measure

These include the walking wheel, measuring materials by the truckload or bucketload, or even “eyeballing” the measurement. As one would expect, these methods are riddled with inconsistencies and inaccuracies.

These methods produce estimates and guesses more than they do data or measurements, and while educated guesses might have a place in some industries and, at one time, may have been the only option possible, new stockpile measurement techniques have almost completely replaced these traditional methods.

Smartphone

If you are on a budget but are still looking for accurate stockpile measurement data, your best option might actually be already in your pocket.

Smartphones can actually work very well as a data collection tool for measuring stockpile volume, and when paired with the right data calculation technology, it can produce accurate and actionable data in 24 hours or less.

There are a number of different stockpile measurement smartphone applications, but most of them work in a similar fashion.

Stockpile Lite app

Stockpile Lite app

One simply sets up their smartphone with the stockpile in frame and walks around the perimeter of the pile. The in-app camera captures a video that you can then review before uploading to the cloud and receiving a report.

These measurements are often highly accurate—even within a couple of percentage points of the higher budget options we’ll explore below—and are perfect for companies who can afford a slightly wider margin of error or who need a lower-cost solution to their stockpile management needs.

Photogrammetry

Photogrammetry is a mapping and surveying process that strings together hundreds and thousands of photographs to create a complex, 3-D model of a subject or location.

Photogrammetry has a number of use cases, but one of the most prominent is in stockpile measurement and stockpile management.

Stockpile volume calculations gathered by photogrammetry collection sensors can be incredibly accurate, but there are a number of factors to consider before a company commits to using photogrammetry as its stockpile calculation method.

Firstly, it can be rather cost-intensive. Photogrammetry sensors are expensive, as are the drones or other vehicles that the data collectors must be placed on (for more information on how drones can be used for stockpile measurements, see the section below).

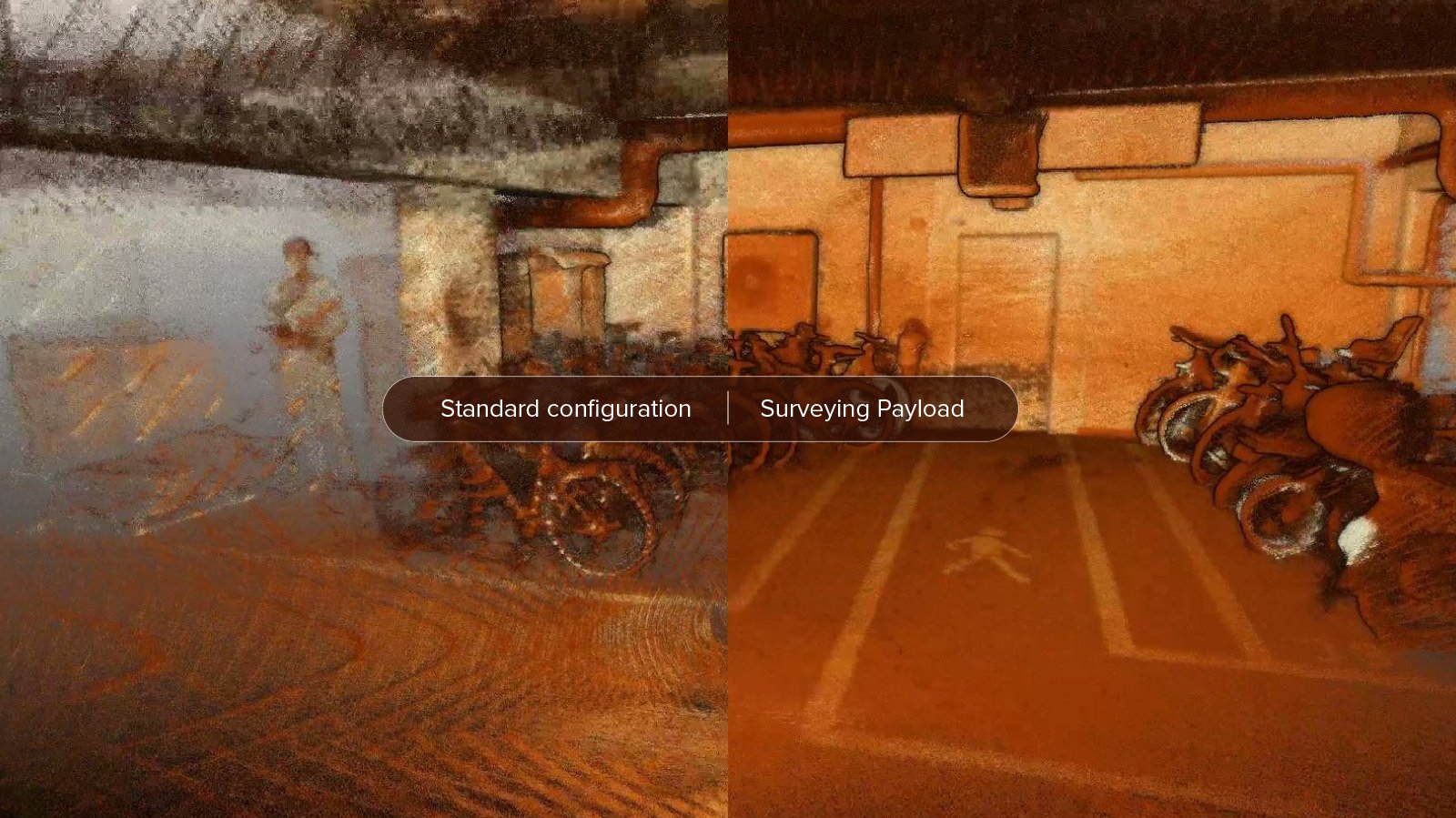

Drone footage on left, photogrammetry 3D model on right

Drone footage on left, photogrammetry 3D model on right

Additionally, photogrammetry technology usually requires a surveyor to operate, which would be best hired in-house if a company requires weekly or daily inventory reports on stockpiles.

That being said, the data cloud that photogrammetry sensors collect is much more complex and accurate than the ones captured on a smartphone.

Though it may take some additional time to process and calculate, one can be assured that if they opt for photogrammetry when measuring stockpiles, they’ll have some of the most accurate data possible.

LiDAR

LiDAR is a technology that operates similar to sonar or radar, except instead of using sound or radio waves to calculate an object’s position, it uses light projected from lasers.

LiDAR systems can be incredibly accurate and can be used to create a 3D map of an area in a manner similar to that of photogrammetry sensors. In many situations, especially in low light, LiDAR is even more accurate than photogrammetry.

LiDAR can be used as a method to measure stockpile volume, though most of the things that considered when choosing photogrammetry as their measurement method of choice must also be considered here. LiDAR scanners can be carried by hand or attached to robotics solutions, like drones.

LiDAR scanners as well as the stockpile measurement equipment required to fully operate with them are expensive, and LiDAR stockpile calculation solutions are likely to only be applicable in specific situations at companies with a larger budget.

Learn more about LiDAR and how it's used across various industries.

Drones for Stockpile Measurement

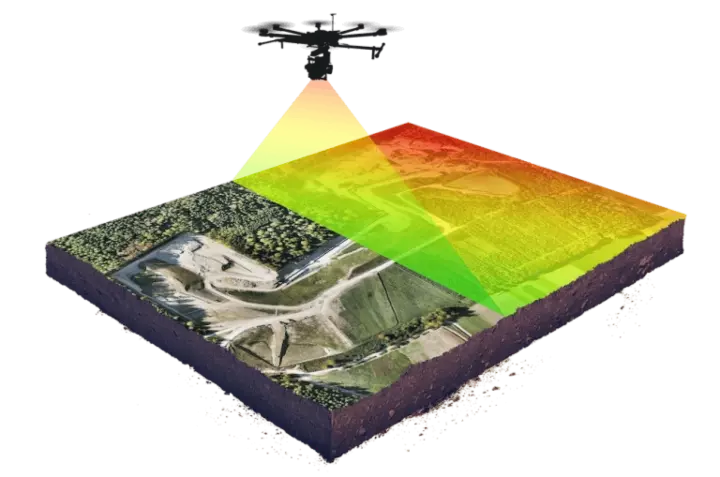

Whether you’re using a camera, a photogrammetry sensor, or a LiDAR scanner, a drone or other UAV is one of the best tools to collect stockpile measurement data since all of these tools and sensors can be attached to a drone.

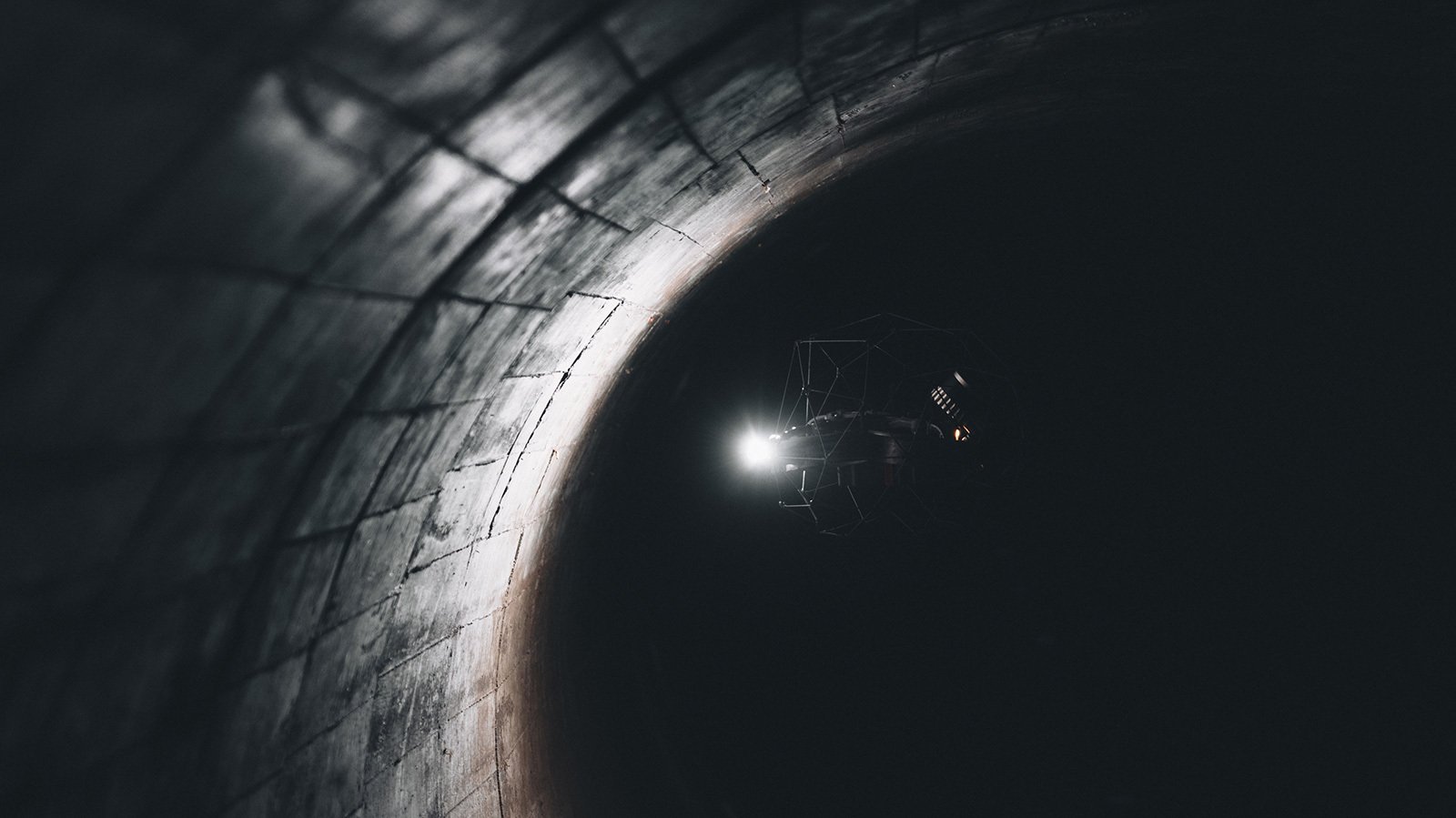

Different situations call for different drones with a variation of payloads and sensors. For indoor stockpile measurement, a drone like the Elios 3—which is built to fly indoors in a dark and dusty environment — might work best.

The Elios 3 entering an industrial asset for an inspection

The Elios 3 entering an industrial asset for an inspection

In fact, the Elios 3 has already been used for complex stockpile measurements across industries including mining, cement, and construction. In one example, the Elios 3 was used to measure stockpiles in a clinker silo, which is traditionally a dark, dusty, and dangerous environment. In another project, the Elios 3 and its LiDAR payload were utilized to do monthly stockpile checks at a cement plant, completing surveys of 30 stockpiles and bunkers in under 2 hours.

For outdoor stockpile measurement, drones that have a long battery life or are capable of multiple flights will work best.

Drones working outdoors at sites with multiple stockpiles will also likely need to be able to carry multiple payloads to work as efficiently as possible.

BENEFITS OF DRONES FOR STOCKPILE MEASUREMENT

Here’s just a few of the ways that drones can benefit a stockpile measurement solution.

- Speed. Drones can cover a large amount of ground in a short amount of time—sometimes even taking multiple flights in one day. At mines or construction sites, a drone can survey acres of land in the time it’d take a person to cover just a few hundred feet.

- Accuracy. A drone equipped with a photogrammetry or LiDAR-enabled payload, such as the Elios 3, will be able to make accurate stockpile measurements within centimeters. Whether indoor or outdoor, no matter the size or makeup of the commodity, a drone can more accurately collect data than any human-run survey solution.

- Cost. While the upfront cost of a drone is higher than some of the other stockpile measurement solutions, like an iPhone, the ROI is worth it. Firstly, you are able to cut down survey and measurement time by days or even weeks by using a drone. Additionally, since drone stockpile calculations are more accurate, the cost and expenses associated with excess inventory are regularly avoided.

- Safety. A final area in which using drones for stockpile measurement can greatly benefit a company is by increasing worker safety. By minimizing exposure to treading on piles of materials, drone-based stockpile management can save money, time, and lives.

UPGRADING STOCKPILE MEASUREMENT TECHNIQUES THANKS TO DRONES

With technology such as LiDAR equipped drones, like the Elios 3, now available for assisting stockpile measurement and management, it is possible work faster and more efficiently than ever before. The digital copies of stockpiles made with laser scans or photogrammetry can be used for clearer reporting, ease of communication, as well as accurate tracking. This visual resource makes it easier to avoid mistakes as well as track changes, which can be used to resolve conflict or confusion in cases of stockpiles being accidentally depleted or overloaded.

The Elios 3 is a vital tool for streamlining complex stockpile measurements, empowering safer, faster, and more accurate data collection in a routine part of industrial work. With the benefits that include improved safety and reduced downtime, the use of drones for stockpile measurement is a massive step forward across industries, and promises to become a part of regular workflows in the near future.