- Blog >

- What IS ALARA?

What is ALARA?

ALARA stands for As Low As Reasonably Achievable and describes the principle that everything reasonably possible should be done to reduce radiation exposure.

In the U.S., following ALARA is a legal mandate for nuclear plant operators. This requirement is described in the Code of Federal Regulations under Title 10, Section 20.1003.

Here is the full definition of ALARA:

ALARA (acronym for "as low as is reasonably achievable") means making every reasonable effort to maintain exposures to radiation as far below the dose limits in this part as is practical consistent with the purpose for which the licensed activity is undertaken, taking into account the state of technology, the economics of improvements in relation to state of technology, the economics of improvements in relation to benefits to the public health and safety, and other societal and socioeconomic considerations, and in relation to utilization of nuclear energy and licensed materials in the public interest.

- U.S. Nuclear Regulatory Commission

Though they may be described slightly differently, ALARA requirements are in place throughout the world.

In this guide to ALARA we’ll cover what ALARA is, how to reduce radiation exposure, and the specific considerations that nuclear plant operators must make to ensure compliance with ALARA.

What Is ALARA?

Maintaining ALARA is a requirement for nuclear plant operators in the U.S. and in many other countries throughout the world.

In nuclear plants, administrators are constantly evaluating new ways to reduce and avoid exposure to radiation for their personnel. It’s important to note that some radiation exposure will be required for work at nuclear plants—but, because technology is constantly changing and evolving, there are always new tools and strategies to help reduce the amount of exposure.

This is why ALARA requires reasonable steps to be taken rather than prescribing a specific list of actions or steps to reduce exposure, since any such list might quickly become outdated, or not be possible in some places due to regional or other limitations.

But ALARA is not only a legal requirement for work at nuclear facilities.

It’s also just a general guideline for any kind of activity, professional or otherwise, that may involve exposure to radiation.

Another way to think about the principle of ALARA is that all radiation exposure should be avoided if it has no direct benefit.

The Center for Disease Control (CDC) words that perspective like this:

“[The ALARA] principle means that even if it is a small dose, if receiving that dose has no direct benefit, you should try to avoid it.”

Direct benefit here means that some kind of benefit or gain should be made every time a person is choosing to expose themselves to radiation. No one should ever allow themselves to be exposed to radiation without getting something in return.

Here are some examples of what a direct benefit could mean:

For a nuclear plant engineer, a direct benefit could be that a nuclear engineer is able to collect important data about the condition of a containment building that will inform maintenance decisions. In exchange for collecting this data, the engineer is willing to expose themselves to some small amount of radiation.

For a civilian, a direct benefit could be that a photographer is able to collect photographs and videos in an area known to be contaminated by radiation—for example, at Chernobyl. In exchange for taking these photos, the photographer is willing to expose themselves to a small amount of radiation.

How to Reduce Radiation Exposure

ALARA is the guiding principle of radiation safety.

Although it may never be possible to completely eliminate exposure to radiation for those who work at nuclear plants, it is crucial to try and reduce that exposure as much as possible. And continuing to find new ways to reduce exposure is at the heart of why ALARA was created.

Most nuclear plants have huge budgets for purchasing new, cutting edge equipment to help them reduce radiation exposure.

And this is why, for most nuclear plants, what might seem like a relatively small reduction of exposure to radiation—reducing it by, say, even 2 minutes or 2% a year for all personnel—would be worth spending hundreds of thousands of dollars.

This can be understood not just as a safety-driven decision, but also as an economic one.

In the nuclear sector, every single day of downtime could represent millions in lost potential revenue. So spending money on tools like drones or robotics in general that can reduce downtimes isn’t just about ALARA—it might also be about the bottom line.

“If you can reduce your inspection time at a nuclear plant—even if it’s just by a single day, or even a few minutes—it can represent several million in potential savings from reduced downtimes.”

- Michael Vanovermeir, NDT Inspector

What Does the Word "Reasonable" Mean in ALARA?

According to ALARA, nuclear plant operators must take every reasonable step they can to reduce radiation exposure for their employees.

But what exactly does “reasonable” mean? Each nuclear plant may face its own unique challenges and circumstances, or conversely have extra means for ensuring compliance.

This is why ALARA has some intentional vagueness built into it. Rather than describe specific guidelines for reducing exposure to radiation, ALARA cleverly puts the onus on nuclear operators to continually seek ways to reduce exposure, making this requirement an active pursuit rather than a static goal.

Below are the four considerations that the U.S. Nuclear Regulatory Commission lays out for determining what is reasonable for a given nuclear plant, taken from the definition of ALARA provided at the beginning of this article.

-

The state of technology—what tools are currently available to help reduce radiation exposure?

-

The economics of improvements in relation to the state of technology—what do those tools cost and can that cost be reasonably met?

-

The economics of improvements in relation to the benefits to the public health and safety—will the cost of those tools be offset by actual harm reduction?

-

Other societal and socioeconomic considerations—as applicable, leaving some extra room for compliance.

ALARA and Radiation Safety

There are three primary ways that nuclear personnel can reduce exposure to radiation:

-

Time—decreasing the amount of time a person is in an irradiated environment.

-

Distance—increasing the distance a person has from an irradiated environment.

-

Shielding—wearing protective shielding to reduce the exposure when working in an irradiated environment.

For most scenarios, all three of these will be used together to reduce radiation exposure as much as possible.

For example, a nuclear engineer might plan carefully for entering an irradiated area in order to collect inspection data so that they can:

-

Do the work as quickly as possibly (Time)

-

Avoid areas within the irradiated area where radiation is highest and where they do not need to go to perform the planned work (Distance)

-

Be shielded from the specific type of radiation present by wearing the appropriate PPE (Shielding)

Here is more information on how each of these three considerations can help to reduce radiation exposure.

1. How to Reduce Radiation Exposure—Time

Time considerations can help reduce radiation exposure by reducing the amount of time spent in an irradiated area.

The longer a person is in that area, the more radiation exposure they will experience.

A simple way to think about using time to reduce radiation exposure is simply to ensure that you are mindful of your time spent in an irradiated area, and get your work done there as quickly as possible.

But there are other ways to think about time when it comes to ALARA and reducing radiation exposure.

One powerful way to reduce time spent in an irradiated area is to use a tool that allows you to either collect data or perform work remotely. For some of the work done in the nuclear industry, robotics solutions can be used to enter an area instead of a person.

For example, inspectors can decrease the amount of time they need to be in an irradiated environment by having a drone take their place for collecting data.

Flyability's Elios 3 drone being used for a remote inspection

The most common type of data drones are used to collect right now is visual—that is, the inspector flies the drone into the “hot” environment, collects video footage reflecting the conditions there, and then flies out.

The inspector can watch the live feed of the footage while the drone is in flight, and can also review the recording later to do a thorough inspection, looking for any defects that might be present within the area.

2. How to Reduce Radiation Exposure—Distance

Distance considerations can help reduce radiation exposure by increasing the proximity of the person to the irradiated area.

Radiation dose is inversely proportional to radiation distance. The closer you get, the higher the dose, and the farther away you get, the lower the dose.

Distance is another area in which robotics can help reduce radiation exposure.

Similar to the time consideration, inspectors can use drones and other robotics to increase their distance from an irradiated area.

For eddy current tests conducted at a nuclear plant, inspectors commonly use a robotic arm to distance themselves from radiation, allowing them to conduct their inspections at a distance that allows them to avoid almost any exposure to radiation.

Drones can also help with distance by allowing inspectors to collect data remotely, letting them fly into areas where radiation is present and capture video data.

3. How to Reduce Radiation Exposure—Shielding

Shielding considerations can help reduce radiation exposure by placing some kind of protective layer between the person and the irradiated area.

When used appropriately, shielding can be a significant tactic for reducing radiation exposure.

The type of shielding you use will generally be determined by the type of radiation you will be exposed to—below are some examples of different types of radiation and associated shielding.

-

Alpha particles only require thin shielding. A sheet of paper or even a layer of dead skin cells can provide adequate shielding for alpha particles.

-

Beta particles require more shielding, but still not much. A small layer of plastic or even a sweater or some comparable layer of clothing can provide adequate shielding for beta particles.

-

Gamma rays require strong shielding. A few inches of lead shielding or some other dense material will be needed to provide adequate shielding from gamma rays.

-

X-rays also require strong shielding. Lead shielding or some other dense material will be needed to provide adequate shielding from X-rays.

ALARA and Radiation PPE

PPE (Personal Protective Equipment) is an important consideration for anyone who might be exposed to radiation.

Considerations for choosing the right PPE to use in a radiation emergency include:

-

Contamination risks—how close will you be to the contaminated area?

-

External contamination—how can you avoid having radiation come in contact with/contaminate your skin, eyes, etc.?

-

Internal contamination—how can you avoid having radiation come in contact with your internal organs via absorption inhalation, ingestion, etc.?

It’s important to note that no amount of PPE can eliminate the threat of radiation exposure. For gamma rays or X-rays, for example, lead shielding in the form of a lead apron can mitigate exposure but should not be counted on to fully eliminate it.

Here are some of the most highly recommended types of radiation PPE:

-

Personal radiation dosimeters

-

Respirators

-

Protective clothing

1. Radiatoion PPE—Personal Radiation Dosimeters

Alarming dosimeters can be used to track your accumulated radiation dose, to manage the amount of time you have been within an irradiated area, and to alert you when radiation spikes.

Geiger Müeller dosimeter counter | Credit: SPW Industrial

Geiger Müeller dosimeter counter | Credit: SPW Industrial

The dosimeter used should ideally be a direct-reading one so that you can easily see its read out and be aware of any warnings or alarms.

2. Radiation PPE—Respirators

Ideally this would be an air purifying respirator with a full face piece.

However, surgical face masks such as N-95s or even face coverings created with available materials such as a T-shirt or sleeve are better than nothing.

3. Radiation PPE—Protective Clothing

Protective clothing (also called dermal PPE, since it protects the skin) can be used to avoid external radiation exposure by keeping radioactive material off of your hair or skin.

The Radiation Emergency Medical Management (REMM) division of the U.S. Department of Health and Human Services describes four levels of dermal PPE:

-

Radiation PPE Level A—Totally encapsulating chemical- and vapor-protective suit.

-

Radiation PPE Level B—Non-gas-tight encapsulating suit

-

Radiation PPE Level C—Gear such as turnout gear, bunker gear, or firefighter protective clothing, including Flame- and water-retardant pants and overcoat or helmet, gloves, footwear, and hoods.

-

Radiation PPE Level D—Could include chemical-resistant jackets, big overalls and coveralls, chemical-resistant gloves, or chemical-resistant inner suits.

Radiation Dose Limits

Personnel at nuclear plants are only allowed to be exposed to a certain amount of radiation every year.

This set amount is called a radiation dose limit, and it is cumulative.

As a nuclear engineer is exposed to radiation over the course of a year, that amount is monitored and tracked. If they reach their radiation dose limit, then they must wait until the next year before they are allowed to work inside a “hot” or irradiated area.

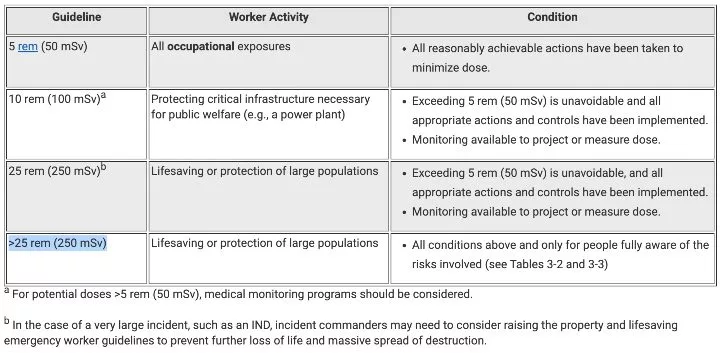

Emergency Radiation Dose Limits

In emergency situations, there are also set radiation dose limit.

Examples of emergency scenarios include those in which workers are injured or trapped inside irradiated areas and in need of help, or scenarios that involve the protection of critical infrastructure.

These limits are viewed as “once in a lifetime” doses, with an expectation that any future radiological exposure will be significantly lower than that received during the emergency.

In the U.S., the federal division of Radiation Emergency Medical Management (REMM) provides the following radiation dose limit guidelines:

-

Common occupational exposure—5 rem (50 mSv).

-

Protecting critical infrastructure—10 rem (100 mSv).

-

Lifesaving or protection of large populations—25 rem (250 mSv).

-

Lifesaving or protection of large populations (only for people fully aware of the risk involved)—>25 rem (250 mSv)

What Is REM?

REM stands for Roentgen Equivalent, Man and is a term used to refer to a unit of equivalent dose. REM helps quantify radiation exposure across all types of radiation.

Here is the REMM's full chart:

The Future of ALARA

New types of drones are now allowing inspectors to decrease the time spent and increase their distance from irradiated areas even more, representing a potential step change for ALARA compliance.

The Elios 3 RAD, for example, is a drone made specifically to collect dose readings in nuclear power plants.

A picture of the Elios 3 RAD

A picture of the Elios 3 RAD

The RAD can be equipped with three different types of dosimeters, or radiation sensors, allowing nuclear engineers and other personnel to collect radiation data remotely instead of having to collect it in person. The Elios 3 and its RAD payload are already in use at multiple nuclear sites, including Europe's largest nuclear waste management site, Sellafield.

As technology continues to improve, new developments will continue to push the boundaries of ALARA, allowing nuclear operators to reduce exposure to radiation even further. Soon, the boundaries of ALARA will adapt to be even lower as we make lower levels of exposure reasonably achievable.