- Blog >

- How you can use the Elios 3 RAD

Benefits in a nutshell

|

Access Using drones to look for radiation helps create heat-maps of radiation without a person having to enter potentially hazardous environments. |

Comprehensive data With the RAD payload, drone pilots can gather data to create a “heat map” of a potentially radioactive or contaminated environment in a range of confined spaces. |

|

Site management The Elios 3 RAD works as both a scout and inspector, providing information that can be used in site management and operational planning.

|

Safety This workflow empowers safer operations with better situational awareness through the RAD payload’s data collection without exposing humans.

|

What is the Elios 3 RAD?

The Elios 3 RAD is a combination of our modular Elios 3 drone and a radiation detection sensor payload that enables radiation drone inspection workflows.

Launched in 2022, the Elios 3 is a specialized drone that is tailored for confined space inspections, whether it is the interior of a pipe or an unknown area in a cave. The drone is equipped with a protective cage and a collision-resilient flight algorithm that enables it to move with confidence in tricky environments. This impact tolerance comes from its innovative design that protects the propellers with the cage whilst specialized flight and motor controls stabilize the drone in case of a collision. All of these features combine to make the Elios 3 the ideal tool for operations that are beyond the line of sight or in enclosed spaces that are too dangerous for human operators.

The Elios 3 RAD is an ideal toolkit for improving safety and speeding up operations related to radiation detection

In 2023, the Elios 3’s modular payload portfolio was expanded to include the RAD sensor - RAD being short for radiation detection. This specialized sensor is created by Mirion Technologies, who are experts in creating tools to detect and measure radioactive materials.

With the Elios 3 RAD, it is possible to detect and measure radioactive material that could be anything from material at a nuclear power plant or old radioactive contaminated assets that are part of nuclear decommissioning projects.

The benefits of using drones to look for radiation include:

- Optimized safety

- A drone can enter environments and scout an area ahead of people in order to determine if the radiation levels are low enough for people to enter or if further safety precautions need to be taken. This pre-survey helps plan operations.

- The drone can look for changes in radiation levels and provide data which can inform fast decision-making and responses.

- Improved data collection

- The Elios 3 RAD can inspect contaminated areas and gather data that tells inspectors about radiation levels, providing information that was previously unavailable with remote sensors.

- The Elios 3 RAD gathers visual, volumetric, and radiological data, providing inputs for both creating a 3D model and a radiological survey with a drone.

- Better access

- By using a drone for radiation inspections, engineers can see more than before. The Elios 3 RAD can inspect assets whether they are contained in a room or high up. This allows for comprehensive data collection for assets that were not previously easy to access.

- The Elios 3 can move into areas without people as it is controlled remotely. It can be used to inspect the insides of assets like pipes - provided it can get inside them (it only needs a 50x50cm space to enter and 60x60cm space to inspect).

- The sensor used for the Elios 3 RAD is the RDS32-WR, produced by Mirion Technologies. They create sensors for radiological surveys and radiation detection around the world and are experts in gathering this type of data, making them the perfect partner for the Elios 3’s inspections.

How can you use the Elios 3 RAD for operations to do with radioactive material? How can drones look for radiation?

The applications for the Elios 3 RAD range from inspecting nuclear power plants to contributing to nuclear decommissioning efforts. We have three key examples of how the Elios 3 RAD could be used.

Radioactive waste warehouse management

Nuclear waste management is a challenging task as it requires safely storing materials that will be radioactive for potentially thousands of years. In some instances where that nuclear waste is sealed off, the Elios 3 has created 3D models inside radioactive environments rather than sending a person in. However, sometimes this waste is stored in carefully constructed barrels that are lined with cement. These barrels are then kept in special storage where they are regularly monitored to ensure the containment is in good condition.

A drone inspection of nuclear waste storage with the Elios 3 RAD in this environment is ideal. The Elios 3 RAD can regularly fly inside the warehouse and gather data on radiation levels, making it possible for the drone to look for radiation and record it. In many environments like this, the “ALARA” rule applies to safety standards around radiation levels: as low as reasonably achievable. This means that you need to put in place everything that is reasonably achievable to make human exposure to radiation as low as possible.

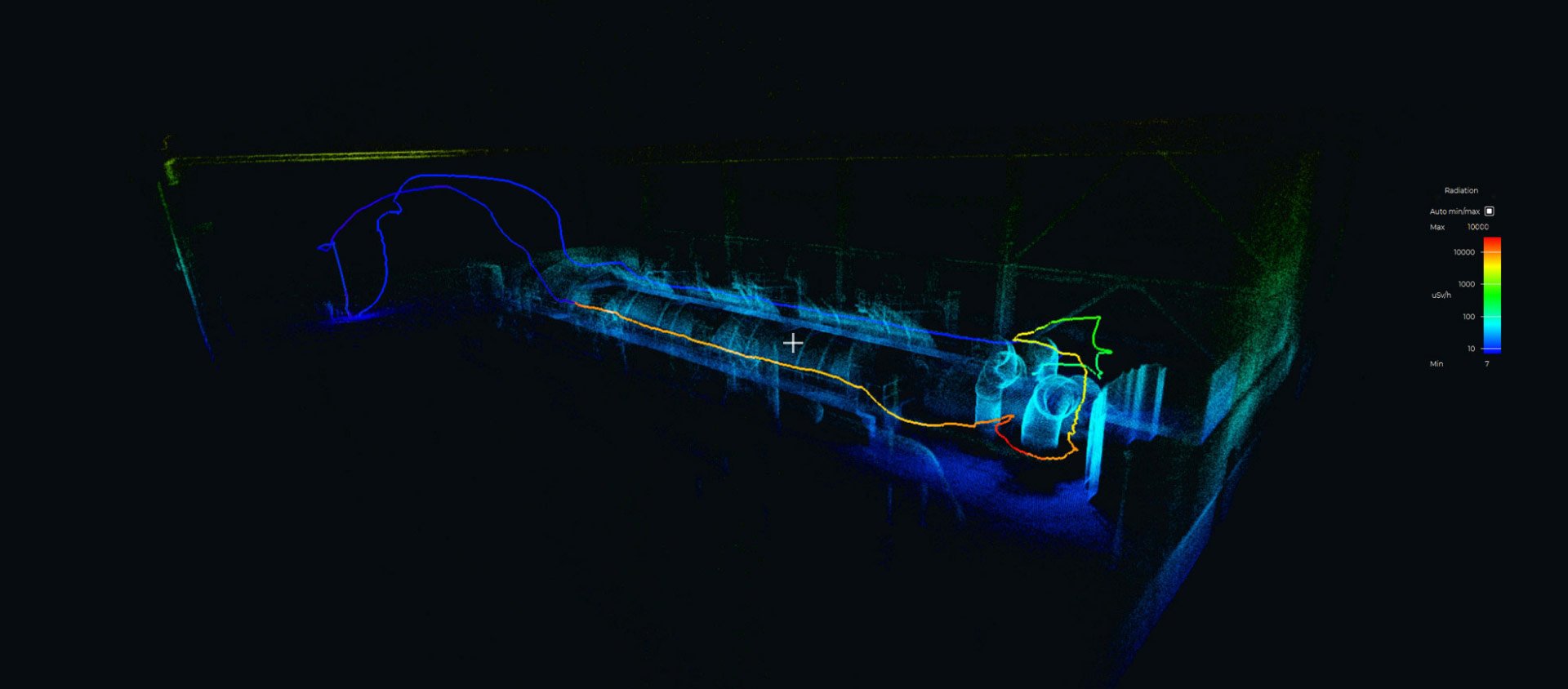

Here a turbine deck has been scanned with the Elios 3 RAD, with the flight path showing the easy access the drone had around the entire asset

With the Elios 3 RAD, a database of inspection readings can be built up and used to monitor any changes in radiation levels. The record of changes can help the radioactive waste management team plan for any maintenance requests or respond quickly if one of the storage areas is compromised. In these cases, the Elios 3 RAD would provide more data coverage with safer methods, reducing the need for human exposure to this environment.

Site scans for radioactive contamination, including powerplants

A simple drone inspection of a nuclear power plant can already save up to $500,000. Safety is critical in these environments as they may include radioactive material. Now, with the Elios 3 RAD, pre-scans of areas can be done before people enter an area to determine the level of radiation in that space as well as conduct a visual inspection.

For example, if there was a potential breach in a pipe that carries potentially radioactive waste at a nuclear powerplant, a drone looking for radiation could provide a quick assessment and gather critical data. It could be used to create a radiation heat map of the room to identify where the breach had occurred and the level of radiation. If the drone is exposed to radiation, provided it has not affected the mechanics of the drone, it can be kept in that area with the only contact needed to be the changing of batteries and the collection of data. This means the Elios 3 RAD can be safely used in a contaminated environment without potentially bringing loose contamination outside of that space. This sealed operational cycle provides situational data with a dedicated tool while maintaining safety standards.

Case studies similar to this example could take place at sites such as nuclear power plants or nuclear decommissioning projects. The Elios 3 RAD presents a game-changing opportunity for improving safety while also enhancing site awareness by gathering more data from hard-to-reach locations.

Underground Radioactive Material storage

A further example of radioactive waste management includes underground storage spaces for direct disposal of nuclear waste. Projects of this nature take place all around the world, where the aim is to reduce the chances of people coming in contact with radioactive materials by burying them deep in an underground repository. Some of these spaces are sealed off entirely whilst others are frequently monitored, such as this Department of Energy site in the United States. This is because the storage areas may require maintenance, such as fixing concrete walls.

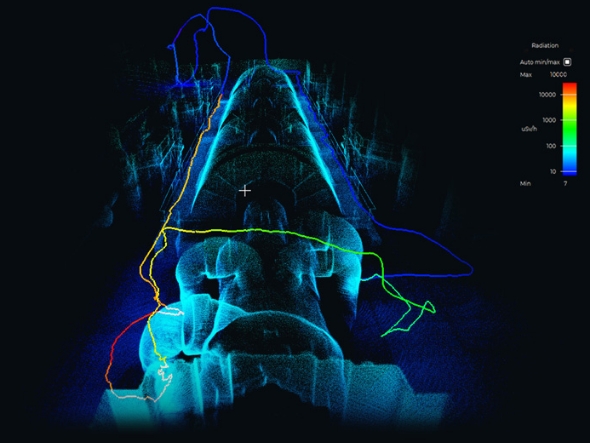

This scan of a turbine deck with the Elios 3 RAD shows clear changes in radiation levels across the area

An Elios 3 RAD could enter these confined spaces and conduct visual inspections of the environment in addition to a radiation survey. This would allow a management team to plan potential maintenance work and reduce the amount of time on-site by having a pre-prepared strategy based on a 3D model created with the Elios 3’s visual inspection. Similarly, the RAD survey ensures that the radiation level is carefully monitored to ensure that the waste being stored is stable and that there has been no leakage.

Radioactive or nuclear waste can include anything from nuclear powerplant equipment, such as heavy water, exhausted uranium fuel rods, or even radioactive cement, to more varied items such as old medical equipment. The careful management of this material can be made more straightforward with the Elios 3 RAD.

The future of drones looking for radiation

The implementation of drones for radiation management presents a big step forward in improving safety for an increasingly complex sector. The applications of the Elios 3 drone with the RAD payload could be used for both nuclear power plants and waste management - where the waste remains radioactive for thousands of years.

With many European countries looking to phase out their nuclear energy plants, including Switzerland and Germany, the challenge of handling the leftover waste and materials and needing the right tools to work on these sites will continue to grow while the need to inspect current nuclear powerplants will continue.

As modern technology evolves to solve modern problems, the Elios 3 RAD offers a new way to gather more data from previously inaccessible areas all while improving safety. It is an exciting step forward in the power generation and waste management sector.

Discover more about the Elios 3 RAD