- Blog >

- A Complete Guide to Corrosion Monitoring

A Complete Guide to Corrosion Monitoring

What is corrosion monitoring and why is it important? Read this guide to learn all about corrosion monitoring, including ways that drones can help.

In any process-intensive industry that uses volatile materials, like Oil & Gas or Petrochemicals, corrosion can be one of the biggest threats to the longevity of assets.

Without proper monitoring, big industrial containers like boilers or pressure vessels can slowly wear down due to corrosion, causing leaks or failures and contributing to poor performance and reliability.

In extreme cases, if corrosion is left unmonitored it can lead to the all-out failure of an asset, and even explosions, posing safety risks to personnel, huge equipment costs, and subsequent environmental damage.

How big are the costs of corrosion?

In the U.S. alone it has been estimated that the total annual cost of carbon steel corrosion is a staggering $276 billion.

And this is why corrosion monitoring and rust detection are so important—because they help mitigate these expenses by preventing the degradation of an asset over time, allowing problems to be addressed before they reach a critical point.

In this article we’re going to take a deep dive into corrosion monitoring and rust detection, with detailed information on what it is, why it’s important, and how it’s done.

We’ll also cover rust detection sensors and corrosion meters that are currently being used for corrosion monitoring, with a special focus on ways that drones can help.

What Is Corrosion Monitoring?

Corrosion is the gradual destruction of a material (usually metals) caused by interacting with chemicals, electrochemical reactions, friction, or some other environmental factor. Corrosion monitoring is thus the process of observing and checking the progress of corrosion over a period of time.

Corrosion often first appears as a discontinuity in a material, such as a discoloration or some other change to its appearance.

This means that what you’re looking for when you set out to find corrosion are any irregularities in the wall or other surfaces that might reveal the existence of corrosion.

If part of an asset, such as a wall or floor, is found to have corrosion, it’s important to begin monitoring its growth so that you can understand how it is changing over time, and have the data needed to recommend maintenance work as appropriate in order to mitigate the damage.

Monitoring vs. Inspecting

Monitoring can happen at the same time as inspecting but the two activities are different.

-

Monitoring focuses on a specific area of an asset and generally happens more often than inspecting

-

Inspecting focuses on the entire asset and generally happens less often than monitoring

When the word monitoring is used in the context of talking about the maintenance of an industrial asset, like a boiler or pressure vessel, it is referring to regular data collection to track changes in a particular area or areas of an asset over time.

In comparison, an inspection refers to a full review of the entire asset, without a specific area in mind. An inspection may reveal corrosion, which will then lead to a recommendation that the corroded areas be monitored.

In addition to focusing on a specific area instead of the whole asset, monitoring generally happens more regularly than inspecting.

While the laws in most countries only require inspections every 3-5 years (depending on the type of asset) monitoring might happen once every quarter if a certain area of an asset appears to be degrading at an increasing rate. For example, if the growth of corrosion on a specific section of a boiler wall seems to be increasing rapidly, quarterly monitoring might be changed to monthly monitoring to make sure the corrosion is being carefully tracked.

If corrosion continues, monitoring may eventually lead to a recommendation that work be done to correct the degradation.

What Exactly Do You Monitor in Corrosion Monitoring?

What you’re looking for when conducting corrosion monitoring is to track the growth of corrosion that has previously been identified.

Tracking the growth of corrosion can be done by using a measuring tool, by taking photographs, by creating an accurate 3D map of the area, or by doing some mixture of these three.

Here’s a list of assets in which corrosion monitoring systems are commonly used:

-

Vessels

-

Boilers

-

Crude oil systems

-

Transportation pipelines

-

Water systems

-

Flowlines

-

Vacuum towers

-

Cooling systems

Why Is Corrosion Monitoring Important?

There are three main reasons it's important to use a corrosion monitoring system:

-

Safety

-

Cost reduction

-

Improved efficiency

Safety

Corrosion monitoring is important for any industry that uses assets that can degrade over time, but it’s especially important in industries that work with volatile materials, which could explode if not stored properly.

As equipment ages it can become more and more susceptible to corrosion, and less resistant to harsh conditions such as high pressures and temperatures.

The goal of corrosion monitoring is to track potential problem areas in equipment so that accidents are avoided and personnel are kept safe.

Cost Reduction

If an asset like a boiler falls apart prematurely due to corrosion it can be incredibly expensive to replace.

In process-intensive industries such as the Chemicals industry, where work is done in refineries or plants which require the use of large storage containers for potentially volatile substances, corrosion can present huge annual costs in terms of damaged equipment.

Corrosion monitoring systems can help companies avoid these expenses by contributing to the longevity of equipment and assets.

Improved efficiency

In addition to helping prevent accidents and cut costs, corrosion monitoring can improve the efficiency of industrial operations by:

-

Extending the life of existing assets and of related operational equipment

-

Providing insights into the kinds of materials that are less likely to corrode for future asset purchasing

-

Contributing to the identification of cost-effective methods for remedying corrosion growth and related issues

-

Identifying conditions related to corrosion in the operating environment—either that contribute to corrosion or that seem to mitigate corrosion—which can then be used to inform purchasing and maintenance decisions

-

Helping to reduce facility shutdown time

How Do You Perform Corrosion Monitoring?

The most important information to collect during corrosion monitoring is:

-

The location and extent of the corrosion

-

The rate of corrosion (i.e., how fast it is spreading over time)

-

The underlying cause(s) of the corrosion

The first step most inspectors take to collect this information is to start with a visual inspection and then proceed to more refined instruments, like using an ultrasonic tester to measure wall thickness, as needed.

Visual Inspection

To conduct a visual inspection of an asset with the goal of monitoring corrosion, inspectors scan the floor, sidewall, or other areas being monitored with their eyes, trying to determine whether:

-

The existing corrosion (i.e., the corrosion that is being monitored) has grown

-

There are new areas with corrosion, as indicated by a discontinuity in the surface of the wall, floor, or ceiling

If the visual inspection indicates that corrosion is growing or that there is new corrosion present, inspectors may want to do a further review of the discontinuous areas with various kinds of non-destructive testing (NDT) tools to quantify the amount of corrosion that is present.

Ultrasonic Testing

One of the most common types of NDT tools used for corrosion monitoring, after a visual inspection has been done, is an ultrasonic tester. These testers use short ultrasonic pulse-waves to allow inspectors to measure the thickness of a corroded wall in order to quantify how much metal or other material may have been lost relative to the surrounding, uncorroded areas.

Although ultrasonic testing is most commonly used on steel and other metals, it can also be used on wood, concrete, and other composite materials.

In many cases, visual and ultrasonic data will be all that’s needed for maintaining a reliable corrosion monitoring system. If these data indicate that the corrosion found is an acceptable amount according to site specifications, the inspector will make a note to continue monitoring the growth and thickness of the corrosion, and will not recommend any maintenance be performed at that time.

Learn more about ultrasonic testing.

Other NDT Testing Methods Used in Corrosion Monitoring

In addition to visual and ultrasonic data, inspectors may choose to use other NDT tools to monitor corrosion.

Some of these testing methods include:

-

Radiographic testing—using electromagnetic radiation to examine the internal structure of a material. Learn more about radiographic NDT.

-

Guided wave testing—using acoustic waves to detect corrosion. This method is ideal for pipelines and similar structures because it can measure corrosion over very long distances—even hundreds of meters, in certain instances—from a single location. Learn more about acoustic emission NDT.

-

Magnetic flux leakage—using a powerful magnet to magnetize steel or other metal and then measuring where there are “leaks” in the magnetic field, indicating corrosion, pitting, or other damage to the metal. Learn more about magnetic particle NDT.

“When deciding on which testing method, technique, or tool to use for corrosion monitoring and rust detection, the most important thing to think about is the job itself, and what it requires. The more you know about what’s out there in terms of NDT tools and monitoring techniques, the more equipped you’ll be to make a choice that will preserve the longevity of the assets you’re in charge of monitoring.”

- Jason Acerbi, General Manager at MFE Inspection Solutions, "Your One Stop Inspection Source"

Corrosion Monitoring Sytems and Techniques

There are several different techniques inspectors might employ when using these different NDT tools for corrosion monitoring and rust detection.

Some of these techniques involve placing a piece of the material from the container being monitored into the same circumstances as the corroded material to observe how it changes, and others involve sending a probe made out of different materials into those circumstances to take readings on the conditions there. In both instances the techniques involve recording change over time in order to understand how corrosion might be taking place from one unit of time—whether it’s a day, a week, or a month—to the next.

Here are some of the most common corrosion monitoring techniques:

-

Creating visual records to track corrosion growth. Using a drone you can spot the presence of corrosion and map the information on blueprints, which can then be compared to future visual records to track the growth of corrosion over time.

-

Monitoring ultrasonic thickness. This is a common technique that uses an ultrasonic tester to scan a wall in order to measure its thickness.

-

Using probes to measure electrical resistance. Probes track changes in electrical resistance, which can be used to track metal loss over time. Probes can provide regular data about the rate of corrosion (monthly, weekly, daily—even hourly).

-

Using coupons. A “coupon” is a piece of material that matches the material in the asset being monitored. The coupon acts as a proxy for the wall or other area being monitored, presenting a fairly simple way to monitor corrosion in almost any scenario. To use this corrosion monitoring technique you place the corrosion coupon—also known as a “mass loss coupon”—into the asset for a predetermined amount of time and then, once removed, test it for type(s) of corrosion, rate of corrosion (if taking multiple readings), and amount of corrosion.

Here are a few less common techniques used in corrosion monitoring systems:

-

Monitoring biological growth. This technique identifies bacteria within an asset that feed on sulphate. These bacteria produce sulphuric acid (H2SO4), which is extremely corrosive, so their presence in an asset means that some amount of corrosion is highly likely.

-

Monitoring hydrogen penetration. Using probes, you can measure the quantity of hydrogen that dissolves into steel. In Oil & Gas, hydrogen is often a byproduct of many of the reactions that take place in Oil & Gas, and its presence can eventually result in the steel becoming brittle and cracking if left undetected and unmonitored.

What Comes Next?

After corrosion application inspectors collect visual or other data on the status of corrosion while conducting corrosion monitoring they may take the following steps:

-

Make a determination about whether the asset is fit for service

-

Review the inspection schedule and make determinations about the need for increased frequency or other changes

-

Develop recommendations to correct/remedy existing corrosion-related problems within the asset

-

Develop other strategies for preventing corrosion, both for the asset being monitored and for other similar assets on site

-

Make predictions about the remaining life of the asset

How Drones Can Help with Corrosion Monitoring

Drones can be incredibly helpful for recording visual information about corrosion.

A good inspection drone can provide a high quality visual representation of an area being monitored for corrosion and rust detection. They can also capture precise data on the location of the corrosion, which can be archived for future reference.

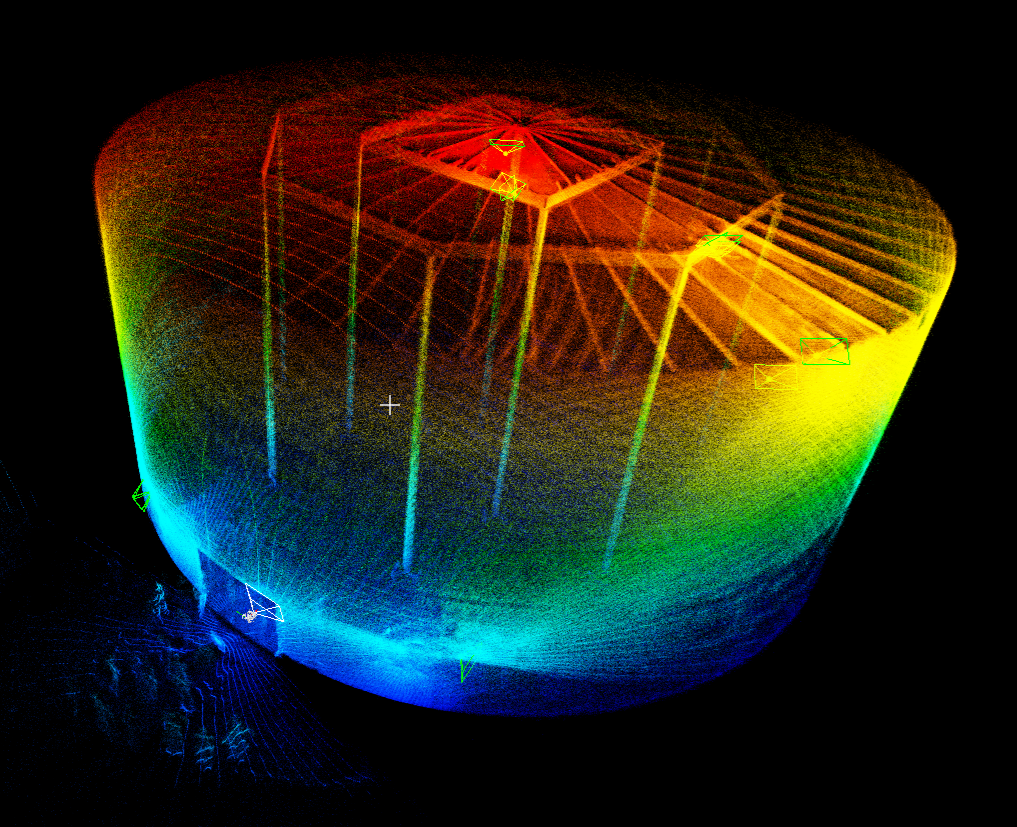

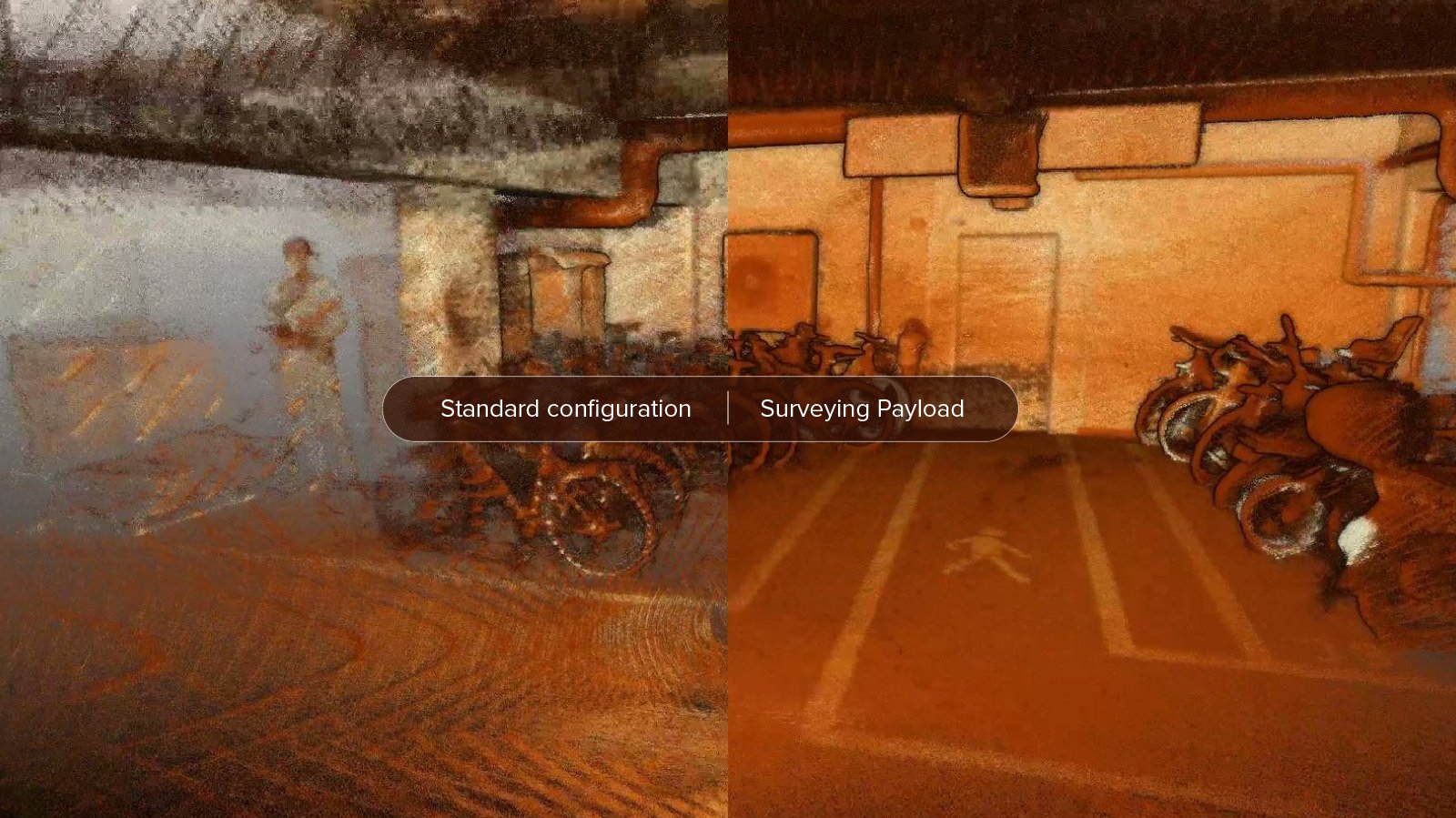

New drones made just for inspections in hard-to-reach places, like the Elios 3, allow a corrosion application inspector to cover more area within an asset, whether it’s a relatively small area being captured with a single image or a large area being mapped using photogrammetry. In the case of the Elios 3, all the visual data captured is measurable and accurate to a high degree. The Elios 3 also carries a centimeter-accurate LiDAR payload that can geolocate points of interest identified by pilots, which means that after the inspection, the drone provides a 3D point cloud with corrosion points geolocated within it, making them easy to revisit or inspect in the future.

Accessing Hard to Reach Places

If inspectors are trying to monitor corrosion or detect rust inside a tank using a Remote Visual Inspection (RVI) tool like a Pan-Tilt-Zoom (PTZ) camera, they’re limited to what they can shoot because the camera can only be dropped into the tank wherever there are access points.

Also, while a PTZ camera allows for remote directional and zoom control, its zooming capabilities are limited and it has no measurement capabilities.

A drone like the Elios 3, on the other hand, can do measurements that have been found to be accurate to within just one centimeter of error for a 2.4 meter length.

The Elios 3 being used to inspect assets along with its UT payload. Image credit: Interocean

Creating an Accurate Visual Record

Another big benefit to using a drone for corrosion monitoring is that it can collect enough high quality visual data to create a visual record of the status of corrosion on a given day.

Even if inspectors can enter the container in which they are monitoring corrosion, the amount of visual coverage they might be able to get with a hand-held camera is not nearly as thorough as what a drone can capture.

In addition to providing an accurate record of corrosion-related changes over time, visual data collected by drone can help provide before/after documentation for maintenance to ensure that remediation efforts like adding a patch or a coat of material to a wall return it to its original condition.

3D Models

Until recently, technology was still somewhat limited when it comes to creating 3D models of the interior of assets like boilers and tankers.

Environmental factors like light, dust, and the visual features present in the asset can make it hard to collect enough visual data to create a full 3D model of its interior.

But Flyability's Elios 3 indoor drone is changing the game. Using a LiDAR sensor, the Elios 3 can create real time 3D maps of assets and confined spaces. These models can serve as a visual record for monitoring corrosion in an asset, just as high quality still images and videos currently do.

Watch this 3D fly through created by live footage take from the Elios 3 from a decommissioned power plant: