- Case Studies >

- Vattenfall Uses Elios 3 to Map No Go Zones in...

Vattenfall Uses Elios 3 To Map No Go Zones In Decommissioned Power Plant

Personnel at a decommissioned power plant owned by Vattenfall used the Elios 3 to create 3D models inside a "no go" zone, improving their understanding of areas where it's not safe for people to enter.

Benefits in a Nutshell

|

Safety Using the Elios 3, personnel were able to fly into places that were off limits to people and collect LiDAR data for making 3D maps of the area, supporting decommissioning work without placing people in harm’s way. |

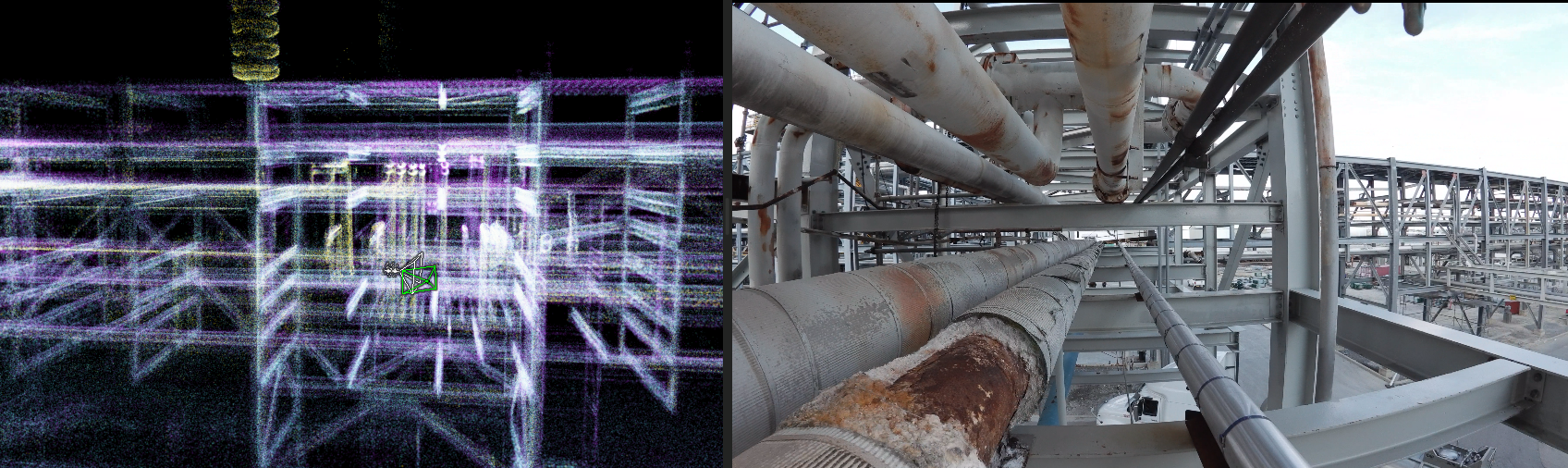

Indoor 3D Maps The Elios 3 was able to create accurate 3D maps within the decommissioned plant, both in real time while the drone was in flight using SLAM (Simultaneous Localization and Mapping) and after the flight using LiDAR data processed with 3D modeling software from GeoSLAM. |

Access Because the Elios 3 is made to operate in confined spaces it was able to fly easily in the complex internal environments present at the power plant, collecting all the data needed for 3D mapping the target area.

|

Inspecting Decomissioned Power Plants

When power plants are decommissioned they may be left abandoned for a long period of time.

There are two reasons for this:

- Safety concerns persist long after a plant is decommissioned, since large industrial plants present hazards associated with falls, head injuries, and the dangers associated with entering confined spaces.

- Security concerns are another reason power plants may be left empty after decommissioning, since the methods used to create power and the distinct design of a given power plant are considered secret, and as such must be protected.

Despite these concerns, power companies that own decommissioned power plants must continue maintaining them. Given the age of some of these plants and the limitations imposed on going into them, companies often have limited knowledge of their layout, which can impede their ability to do ongoing maintenance.

Planning a Power Plant Inspection with Drones

Vattenfall is one of Europe’s largest producers and retailers of electricity and heat. The company has about 19,000 employees, and sells energy across Europe, with a strong presence in Sweden, Germany, the Netherlands, Denmark, and the U.K.

The particular power station where Vattenfall was working for this case study is an old, decommissioned plant that has been out of operation for the last couple of decades.

Flyability and Vattenfall personnel walking on the safe side of the No Go zone

After the plant was shut down it was emptied and converted into a training site for the local fire department. But there are still parts of the plant where people are not allowed to go due to the risk of falling objects and other safety hazards, which are cordoned off by fences and cables.

Vattenfall's Research & Development team wanted to find new robotics solutions that would allow them to create 3D maps of the areas in the plant that no one had entered for several decades.

Vattenfall is already a Flyability customer. When its personnel learned that Flyabilty was developing the Elios 3, an indoor drone equipped with a LiDAR sensor for creating detailed 3D maps in confined spaces, they decided to test the new drone at the decommissioned plant to gauge its ability to map places that were too dangerous for people to enter.

The Elios 3 SLAM (simultaneous localization and mapping) algorithm, which is called FlyAware, uses LiDAR data to create 3D models in real time, while the drone is in flight. The LiDAR data it collects can also be converted into more detailed 3D models after a flight using software from Flyability’s partner FARO (previously GeoSLAM).

Vattenfall’s R&D team wanted to see whether the SLAM-generated 3D models and the post-processed 3D models could meet their needs for better understanding the layout of the plant.

A pilot prepares to fly the Elios 3 in a No Go Zone

Drone Flights Inside a Decomissioned Power Plant

The mission was a success. It demonstrated the Elios 3’s ability to enter areas that can’t be entered by people—either due to safety concerns or simply because they are inaccessible—and create 3D models of those areas.

The area the Vattenfall team selected for testing the Elios 3 was an old staircase within the power plant that was off limits for human entry.

The staircase where the 3D mapping was conducted

The Vattenfall R&D team found that both the SLAM-generated models and the post-processed 3D models provided all the materials needed to support their decommissioning efforts, indicating that it could be used for the same work at other plants going through the process.

“The LiDAR capability is a great addition to the Elios' capability’s and it is so far the only drone with LiDAR capability in this size segment”.

- Anders Lindstrom, Digital Inspection Specialist in the R&D Department at Vattenfall

Personnel from Vattenfall were able to fly the Elios 3 into the protected area. Using the Elios 3’s LiDAR sensor, an Ouster OS0-32 that has an ultra-wide field of view made to create uniformly spaced point clouds, Vattenfall’s R&D team was able to collect all the data they needed to create detailed 3D models of the area.

Here is a 3D fly through of a staircase inside a No Go zone at the power plant created with LiDAR data collected by the Elios 3:

To map the entire area the drone had to fly about 30-40 meters (98-130 feet) up the stairwell, demonstrating its ability to fly a long distance from the pilot while maintaining a strong signal.

Without the Elios 3, Vattenfall personnel would have had to use rope access and possibly erect scaffolding to enter the area and collect data on its condition. With just 30 minutes of flying they were able to collect all the data they needed, saving weeks in time and labor, as well as avoiding the potentially high cost of erecting scaffolding.

The Elios 3 in Nuclear Energy

After creating the 3D models of the stairway in the plant, the R&D team shared them internally at Vattenfall to showcase the innovations they were exploring to enhance safety in the company’s work.

These innovations were well received by Vattenfall stakeholders, who were especially impressed by the Elios 3’s ability to generate 3D maps of areas that are too dangerous to enter.

After these successful tests of the Elios 3, Vattenfall personnel are confident that solutions like this are the future, and that the capability for accessing dangerous areas and creating 3D models of them with a drone solution is a big benefit to their work.

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)