- Case Studies >

- Testing the Elios drone at a High Altitude Mine Located in...

Testing The Elios drone At A High Altitude Mine Located In The Andes Mountains

The Elios 2 was tested at a high altitude mine located almost 3 miles high in the Andes Mountains, meeting all the expectations of the mining personnel.

Benefits In A Nutshell

|

High Altitude Capabilities Operating at an altitude of 4,600 meters (2.86 miles), the Elios 2 was able to operate as expected and collect all the visual data required to satisfy the needs of mining personnel. |

3D Models High quality 3D models and sparse point clouds allowed mining personnel to visualize the conditions inside the mine, improving safety, identifying extra ore, and allowing for precise locational awareness within the mine. |

Access & Lighting Flying inside chimneys, stopes, and orepasses, the Elios 2 was able to access even the most hard-to-reach places within the mine and light them sufficiently to collect the visual data needed. |

Mining at high altitude

Volcan Compañía Minera SAA is a Peruvian mining company that has been in operation since 1943. It operates several silver, zinc, copper, and lead mines, as well as hydroelectric power plants.

Many of Volcan’s mines are located high in the Andes Mountains, a range that runs through much of the western side of South America.

Given their location, operating these mines comes with unique challenges due to the extremely high altitude, and any new equipment used in Volcan’s operations for these high altitude mines must be vetted for work in an oxygen-depleted environment.

Volcan’s Andaychagua mine is one of the biggest that Volcan runs.

The Andaychagua mine

The mine is located in Campamento Minero, at almost three miles above sea level (4,600 meters or 2.86 miles above sea level, to be exact). This extreme altitude imposes limitations on the kinds of robotics used in the mines, and means that solutions that might work for mines located at lower altitudes may not be viable there.

The mine has two entry points, which can be accessed using one lane roads, and goes to a depth of 1,200 meters (3,937 feet, or ¾ of a mile).

The mine is constantly operating. Blasting happens every day at 6 p.m., after which personnel truck out ore all night. During the day, from 7 a.m. until 6 p.m., the mine’s workers secure and inspect the mine, preparing it for the next round of blasting.

All of this constant work yields a huge amount of ore. Every single day about 2,500 tonnes of minerals—that’s 5,511,557 pounds—is extracted from the Andaychagua mine.

Flying a drone inside a high altitude mine

Administrators at the Andaychagua mine are always looking for cutting edge tools to help cut down costs and improve safety for their operations.

When they learned of Flyability’s Elios 2, a drone made just for operating in harsh internal conditions, they wanted to see whether it might work at the extreme altitudes in which they operate, so they decided to test it.

These were the primary areas of focus for the test:

- Capabilities. Can the Elios 2 operate indoors at 4,600 meters (15,091 feet) above sea level?

- Visual data. What kind of visual data can the Elios 2 capture inside of a mine? And what is the quality of that data?

- Lighting. Will the Elios 2’s lighting be sufficient to see the level of detail needed when inspecting the mine, or will additional lighting be required?

- 3D models. Can 3D models be created of areas within the mine using data from the Elios 2? And how long will it take to create these 3D models?

Surveying a high altitude mine with the Elios

Despite the challenges that came with flying the Elios 2 at high altitudes, Volcan’s test at the Andaychagua mine was a success.

The Volcan team was able to perform all of the inspections it had planned for the test, and the drone thoroughly met the team’s expectations.

Here were the results of the test:

- Capabilities. Can the Elios 2 operate indoors at 4,600 meters (15,091 feet) above sea level? Yes, the Elios 2 was able to operate well despite the challenges presented by the high altitude.

- Visual data. What kind of visual data can the Elios 2 capture inside of a mine? And what is the quality of that data? Yes, the Elios 2 was able to collect high quality visual data, which satisfied all the requirements for the mining personnel.

- Lighting. Will the Elios 2’s lighting be sufficient to see the level of detail needed when inspecting parts of the mine, or will additional lighting be required? Yes, the Elios 2’s lighting was sufficient and no external lighting was needed.

- 3D models. Can 3D models be created of areas within the mine using data from the Elios 2? And how long will it take to create these 3D models? Yes, both detailed and sparse 3D models were created using data from the Elios 2.

In total, about 40 flights were conducted in the mine. The assets that Volcan personnel wanted to inspect in the mine included:

- Chimneys

- Ore passes

- Ventilation tunnels

- Stopes (a mining excavation that takes the form of a step or a notch)

In all of these places, mining personnel wanted to collect visual data showing them the conditions within that area of the mine. They also wanted to use that data to create 3D models that would let them further visualize conditions within these different environments.

In total, four 3D models were made from the test, including models of both stopes and tunnels.

Detailed 3D models were made using software from Pix4D.

These models were accurate enough that they could hypothetically be used to identify extra ore within the mine, and help with planning future work. These models required several hours of processing time.

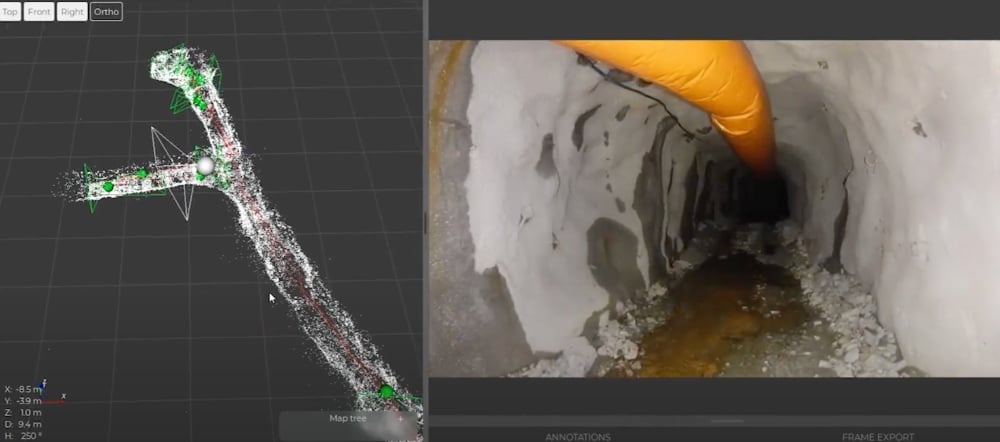

Here is one of the 3D models made from data collected during the Elios 2 test:

Sparse 3D models were also made using Flyability’s Inspector 3.0 software.

These models allowed mining personnel to quickly identify the location of different points of interest seen in the visual footage the Elios 2 collected. These models only required about 20-30 minutes of processing time, so they could be used much more quickly than the detailed models.

Here is a screenshot of a sparse point cloud next to a still Point of Interest (POI) image in the Inspector 3.0 software:

High Altitude Considerations with drones

Flying a drone at such high altitudes required a lot of preparation—here are the best practices Flyability’s team followed with the Elios 2 to complete this mission successfully:

- Flight time. Expect flight time to be reduced by as much as 30% by the drone’s motors working harder in the low air density found at high altitudes.

- Motor maintenance. Because the extra work can make the drone’s motors overheat more easily, let the motors cool down for around 10 minutes between long flights.

- Long ascensions are hard. The low air density at high altitude makes long ascensions difficult due to overheating. To help with this issue, fly down from the top of a chimney instead of flying up from the bottom, and consider using a fishing line to manually lower the drone to reduce stress on the motors.

- Fishing line. When operating in orepasses and chimneys at high altitudes, it’s a good idea to attach a fishing line to the drone since the motors overheat easily and the potential windraft makes it hard to retain control.

- Temperature considerations. Let the drone adapt to the temperature and humidity by leaving it out of the box for 10-20 minutes before starting to fly. Also, don’t forget to clean the lens of the drone before starting the flight.

- Wind considerations. Since you’ll have to fly in Altitude mode, keep in mind that you will have to fight the wind manually as you pilot the drone.

Given the success of the test, administrators at Volcan Compañía Miner are currently considering adopting the Elios 2 for their inspections at the Andaychagua mine.

Now that they know it can operate at high altitudes, they’re also considering using it at several other mines they run, all of which are located in high mountainous areas throughout the country of Peru.

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)