- Blog >

- Mining Industry: A Complete Guide

Mining Industry: A Complete Guide

The mining industry involves the discovery and extraction of naturally occurring minerals from the earth.

Since the beginning of civilization, clay, stones, and metals found close to the earth’s surface were used to make tools, weapons, vessels, and goods for wealth and trade.

Fast forward to the 21st century and the global mining industry is booming. Elements and rare minerals are in high demand as a result of new technologies.

Although there are still major environmental concerns in relation to mining, the mining industry has become more efficient by developing technology that allows miners to extract maximum ore at deeper depths in underground mines.

What is the Mining Industry and Why is it Important?

Mining is the process of extracting minerals from a seam, vein, reef, lode, or placer deposit in the earth. Coal, metals, oil shale, rock salt, potash, gemstones, limestone, clay, chalk, stone, and gravel are all extracted in mining.

Recovery of this raw material is based on the economic viability of investing in labor, mining tools, energy to run mining operations, refining, and transport.

The mining industry accounts for prospecting, planning and permitting the mine, extraction of raw minerals via surface mining and/or underground mining techniques, processing and mineral dressing, and the restoration or reclamation of the mine at the end of its economic life cycle.

Mining also includes extracting non-renewable resources like natural gas, petroleum, and water—however, these resources are not considered to be part of the mining industry.

In general, there are three main processes that take place at the site of an active mine:

-

Mineral extraction: the process of using surface mining or underground mining techniques.

-

Mineral handling: the process of sorting raw materials from waste materials, called tailings.

-

Mineral processing: the process of crushing, grinding, smelting, or refining minerals into a final product for distribution.

Mining is necessary to provide fuel for energy, building materials, and minerals for modern electronics and other consumer products.

A processing plant roaster used for extractive metallurgy

A processing plant roaster used for extractive metallurgy

The Life Cycle of a Mine

The life cycle of a mine, as defined in more detail below, begins with prospecting, leads to extraction, and ends with reclamation of the land.

Prospecting and Discovery

Prospecting involves searching the field for minerals or other precious metals with the following tools and techniques:

-

Metal detecting. This is mainly used to detect gold, nickel, cobalt or other ferromagnetic materials up to a meter below the earth’s surface.

-

Prospecting pickaxe. Pickaxes are used to collect samples of rocks and minerals to be tested. Magnets are sometimes used to find trace amounts of ferromagnetic ore, including nickel, cobalt, and iron.

-

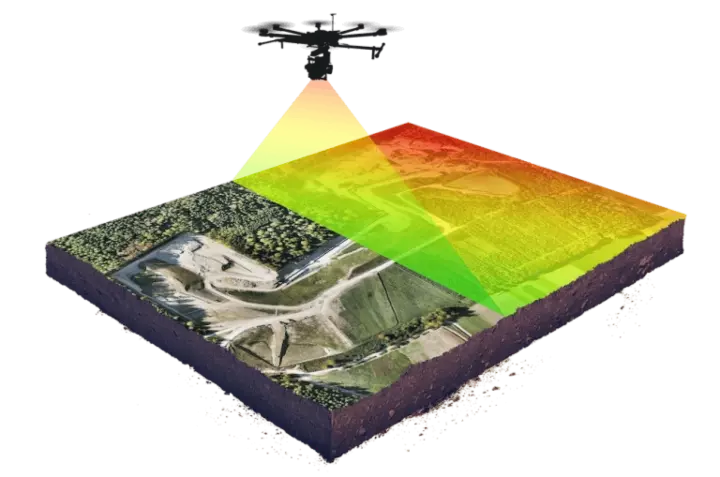

Electromagnetic prospecting. Airborne gravimeters and magnetometers can detect minerals that are up to a few kilometers beneath the earth’s surface. Low frequency electromagnetic (EM) waves are also being used to identify orebodies. The sound waves respond differently to different materials and create 3D depictions of what lies beneath the earth’s surface. This method is used for conductive materials like coal.

-

Geochemical prospecting. With this technique, an abundance of materials—like gasses, water, rocks, plants, and animals—are collected and tested for abnormalities.

After pinpointing an area where the ore is present, the extent and potential value of the orebody will be assessed.

Prospector taking water samples

Prospector taking water samples

Estimation of Ore Size

Once an orebody is identified, mathematical calculations will determine the size and grade of the ore. These estimations will inform the feasibility to extract the ore for economical gain.

At this stage, project managers will determine risk factors and whether or not it’s worth investing more time in the project.

Calculating Economical Feasibility

At this stage, the mining company will decide whether to develop the mine or to abandon the project based on economical feasibility. The mining company will consider the following when making a decision:

-

The economically recoverable portion of the ore

-

The production, processing, and purification of the mineral

-

The marketability and ROI of the ore

-

Engineering implications

-

Milling and infrastructure costs

-

Financing and equity

-

Land reclamation cost and plans

-

Other financial risks

Development

Once a mining company determines an orebody is worth recovering, mine processing plants and other buildings are constructed and mining equipment is obtained. Mine development begins and the operation will continue until the mine is economically void.

Overburden Removal

At this stage, mining begins. The rock and soil that lies above the ore, known as overburden, will be removed to gain access to the orebody. Overburden can be stored on site and is sometimes used to backfill mines once they have been depleted of the ore. Overburden waste removal and storage takes careful planning.

Removing overburden

Removing overburden

Waste Management

Waste management plays a huge part in planning a mine’s operations since a majority of materials removed from a mine are waste, called tailings. Tailings can be sterile or toxic and are stored in closed systems like man-made ponds in valleys or rivers that are dammed to contain the waste materials.

Unfortunately, these systems are not fail-safe. Dams can fail and toxic tailings can make their way into rivers. Surrounding lakes can collapse if too much saline mine water leaks. And in developing countries, tailings can be disposed of directly into the ocean. These leaks, seeps, and spills have massive environmental implications that directly affect humans and ecosystems alike.

Mineral Processing

Mineral processing, also known as mineral dressing, involves crushing, grinding, washing, and separating the minerals from waste materials. These minerals are then reduced into marketable metallic forms by smelting or electrolytic reduction.

Reclamation

Reclamation is the final stage of a mine’s life cycle. Once the mine is no longer economically feasible, reclamation of the land begins. Old mines have been turned into agricultural crops, forests, and public works centers.

In modern mining, reclamation is an essential part of planning a mine. In the United States, mining companies will not be issued a permit if there is no plan for reclamation. Cultural implications must also be addressed within the community.

Reclamation of a surface mine

Reclamation of a surface mine

Types of Mining

There are two types of mining: surface mining and underground mining. Surface mining is much more common than underground mining.

There are also two main types of ore deposits that are mined by both surface mining and underground mining techniques:

-

Placer deposits. Placer deposits are found in rivers and streams and in beach sands.

-

Lode deposits. Lode deposits are contained within rock bodies through layers, veins, or in mineral grains.

Surface Mining

Surface mining activity takes place at the surface level of the earth. Overburden will be removed to expose the orebody below.

Surface mining methods include:

-

Strip mining. Strip mining uses dragline excavators to remove the overburden from the surface of the earth to reveal the orebody. Strip mining is also used to prepare the land for open pit mining, quarrying, and mountaintop removal mining.

-

Open pit mining. Open pit mining is a technique that involves drilling into the earth’s surface to set explosives. The explosions expose underlying rock and cause large pits for miners to be able to extract the ore. This surface mining technique can be used to extract silver.

-

Quarrying. Quarrying, another form of open pit mining, is used to extract slabs and byproducts of marble, granite, and other hard stones.

-

Mountaintop removal mining. Mountaintop removal mining is used primarily in the Appalachian Mountains to extract coal. The top of the mountain will be cleared into adjacent valleys and the top 300 meters will be blasted to reveal coal seams in an open pit mine.

-

Highwall mining. High wall mining is used to extract remaining coal from a seam by using a continuous miner. This is used in conjunction with strip mining and open pit mining and serves as a way to target coal seams from the sides when there is a thick layer of overburden on top of a seam.

-

Placer mining. Placer mining uses a combination of water and pans to extract gold and other precious metals that are found in sand and gravel. These precious metals have a higher density than water and will sink faster than the surrounding materials.

-

In-situ leach (ISL) mining. In-situ mining is a mining technique that’s a bit of an outlier, using neither surface or underground mining techniques. Instead, valuable materials are dissolved in place with water, carbonate solutions, or acid without having to remove the surrounding rock.

An open pit surface mine

An open pit surface mine

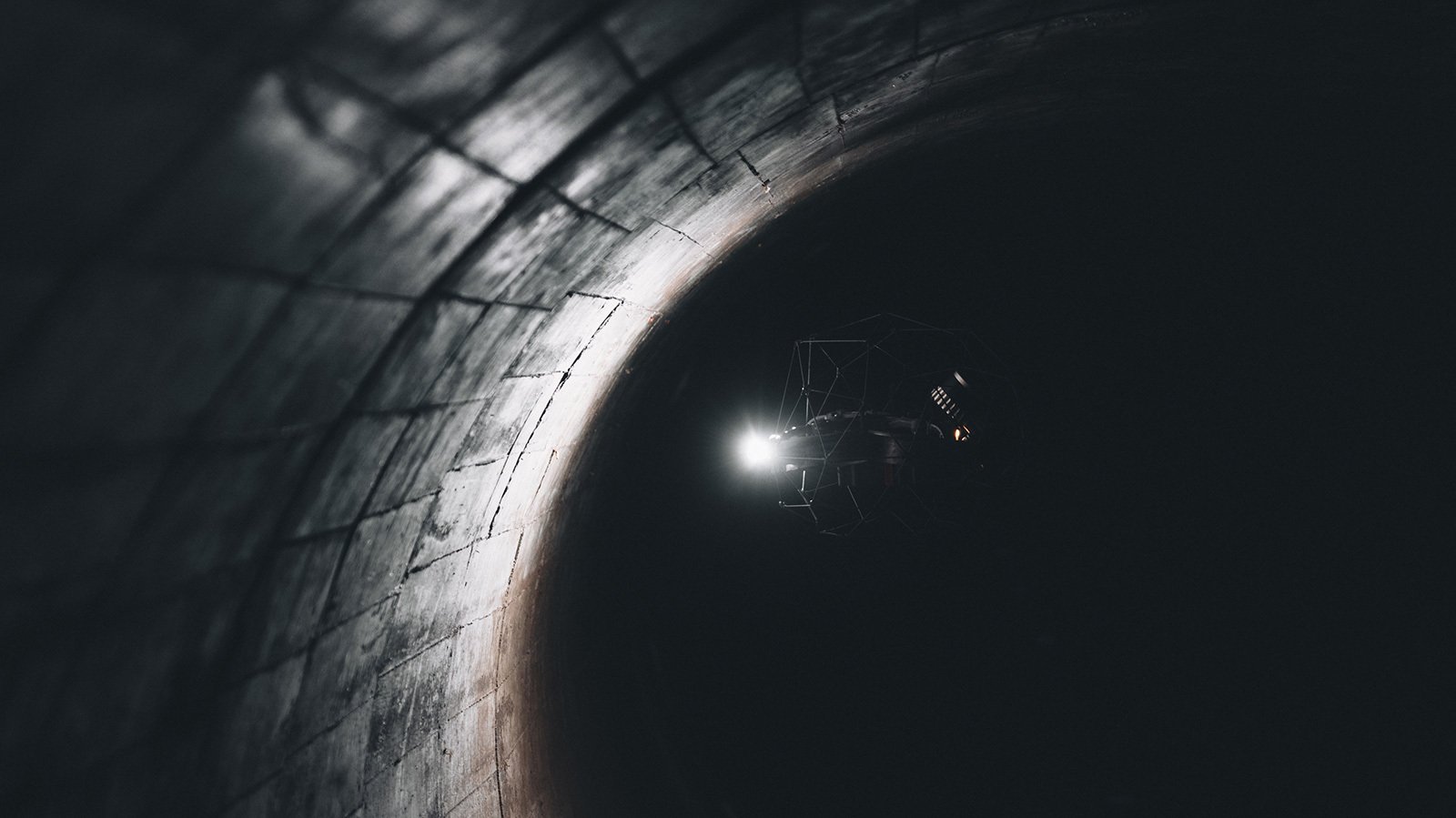

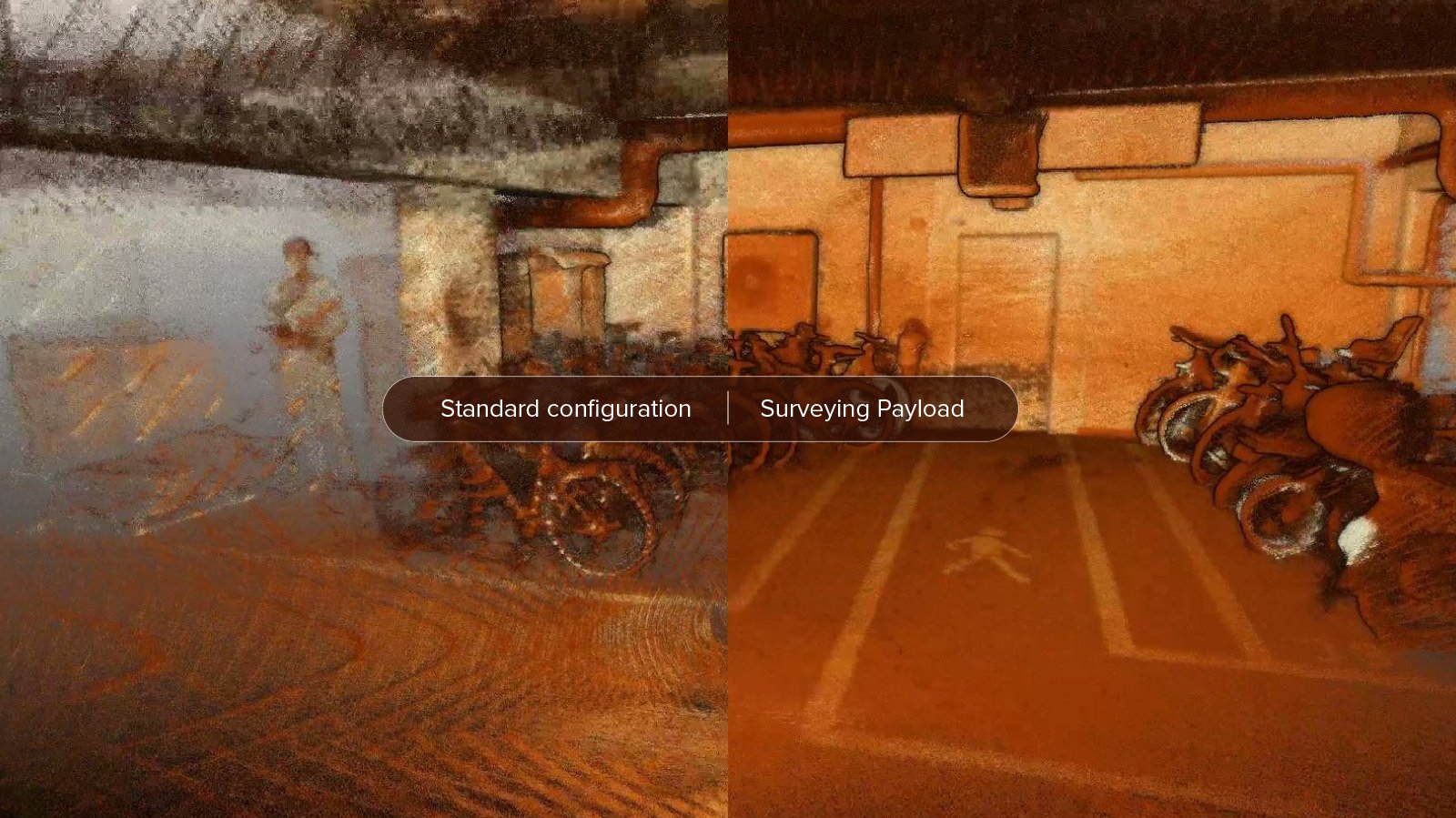

Underground Mining

Underground mining, also known as subsurface mining, consists of digging or blasting tunnels and shafts into the earth’s crust to reach buried orebodies. Ore deposits and tailings are brought to the surface to be refined by onsite processing plants.

Mining hard rock versus soft rock calls for different underground mining techniques and must be taken into consideration when choosing the right extraction method.

There are three different types of access tunnels used to extract the ore:

-

Drift mining: uses horizontal access tunnels.

-

Slope mining: uses diagonally sloping access shafts.

-

Shaft mining: uses vertical access shafts.

Below are the main types of underground mining methods:

-

Room and pillar mining. Room and pillar mining consists of clearing out a room of ore, but leaving pillars in place to support the weight of the ceiling until the ore has been cleared from the stope.

-

Retreat mining. Retreat mining follows room and pillar mining and is the process of removing the pillars from the room, thus extracting the remainder of the ore. This process is strategically executed and can be incredibly dangerous as the mine collapses onto itself during the removal process.

-

Shrinkage stope mining. Shrinkage stope mining, also known as sublevel stoping, is used to recover minerals from steep orebodies. Pillars are excavated and then backfilled at different sublevels. Then the host rock between the backfilled stopes are excavated using the same process.

-

Sublevel open stoping. Sublevel open stoping, also known as blasthole stoping or long-hole stoping, is used when a strong rock body is present and no structural support is needed to extract the ore. Drifts are drilled and the host rock is blasted in slices towards the open face. This method is used to extract lead and iron.

-

Cut and fill mining. Cut and fill mining is carried out by mining horizontal slices from the bottom of the orebody to the top. Drifts are mined and backfilled before moving up to the next level. This method is used for soft host rock.

-

Sublevel caving. Sublevel caving is used to mine the footwall side of an inclined orebody. This method mines from the top down and uses blasting to extract the ore, causing the host rock to cave.

-

Block caving. Block caving undercuts massive orebodies and creates voids under the loosened rock. Ore collapses into the voids and is transported to a crusher through ore passes. During extraction, the surface of the mine will cave in as the ore is removed. This method is used for massive but weak orebodies and has a more involved preparation process than other mining methods.

-

Longwall mining. Longwall mining is used to extract coal from seams that are not accessible from surface mining techniques. These seams are relatively thin and lay horizontally. Coal is extracted with a longwall mining shearer which is set on tracks that can run up to a kilometer.

-

Drift and fill mining. Drift and fill mining is similar to cut and fill mining but the orebody is wider than a drift, meaning a drift will be mined and then another one beside the drift will be mined until the full width of the orebody has been mined. Then that level will be backfilled before continuing up the mine.

A loader clearing an underground mine drift

A loader clearing an underground mine drift

Artisinal Mining

Although a majority of this resource covers large-scale mining (LSM) practices, another important sector of mining includes artisanal miners or small-scale miners (ASM). Artisanal miners consist of independent subsistence miners who mine minerals using traditional hand tools.

General types of artisanal miners include:

-

Seasonal artisanal miners. Migrant miners who work the fields in the wet season and mine in the dry season when crops are idle.

-

Rush-type artisanal miners. Miners that rush to the mines when the price jumps for a commodity.

-

Shock-push artisanal miners. Poverty driven miners who mine following a natural disaster or conflict.

-

Permanent artisanal miners. Miners who are consistently mining.

Artisanal miners are common in rural parts of developing countries, but they also make up over 90% of the world’s mining workforce. Many artisanal miners have few economic opportunities and turn to mining to support their families.

Mining Industry Equipment

Mining industry tools include the largest land equipment on earth. Dragline excavators and dozers are used to excavate overburden; drills are used to set explosives; loaders and haulers help transport ore and waste; and hoppers and trommels are used to separate ore from waste.

Elevator shafts transport personnel to and from the mine sites and also can be used to transport ore from the bottom of a mine up to the surface in an overhand stope. Railways are also used to transport materials to other parts of the mine.

There are also a number of autonomous machines that operate in mines—from haulers and loaders to continuous miners.

Massive dump trucks and cranes move large quantities of ore and overburden in surface mining. Crushers, reactors, mills, and roasters are used in on-site processing plants to extract the desired product from the ore.

Highwall miners mine coal seams from the sides

Highwall miners mine coal seams from the sides

Mining Industry Safety

Due to the scale of mines, complex mining equipment, exposure to toxins, and seismic activity, safety is a huge concern in the mining industry. Although mining accidents still occur, the mining industry has gotten substantially safer over the decades.

In the United States, the National Occupational Research Agenda (NORA) has identified the mining industry as a priority in its research to provide intervention strategies to help improve the health and safety of miners and the environment.

And in 1978, the Mining Safety and Health Administration (MSHA) was established to increase the health and safety of miners in the workplace. Miners can report hazardous conditions to the MSHA.

Mining industry hazards include:

-

Exposure to toxic rockdust

-

Exposure to harmful gasses

-

Exposure to excess heat

-

Hearing loss from loud equipment

-

Rockfalls

-

Cave-ins

As a result, miners are equipped with personal protection equipment to mitigate these hazards, including:

-

Air respirator systems

-

Hearing protection

-

Protective eyewear

-

Detection solutions

-

Protective headwear with cap lights

-

Fall protection

-

Reflective clothing

-

Protective 2-way communications

-

Personal emergency respiratory

-

Extra batteries

Underground mines typically have refuge chambers that can hold miners up to eight days in the event of a hazardous exposure. These chambers store food and water for miners in case of an emergency.

Refuge chamber in an underground mine

Environmental Impacts of the Mining Industry

There are direct and indirect environmental impacts of the mining industry that occur both during the mining process and after the mine has closed.

Environmental impacts include:

-

Deforestation

-

Loss of biodiversity

-

Soil contamination

-

Groundwater contamination

-

Surface water contamination

-

Sinkholes

-

Erosion

-

Poor air quality from carbon emissions

As a result, some countries have implemented regulations on the mining industry to help mitigate these impacts. After a mine is closed, reclamation practices are often required to help recoup the environmental biodiversity.

Surface water contamination

Surface water contamination

Mining Industry Regulations

Mining industry regulations have proven to create a safer working environment for miners, improve the impacts on the environment, lessen local human rights violations, and reduce the number of resource conflicts.

Environmental Regulations

Mining companies are required to follow regulatory practices to avoid impacting human health and to minimize the environmental impact of the mining industry.

Regulations include:

-

Mine closure planning (i.e. reclamation)

-

Developing environmental management plans

-

Assessing the environmental impact of a mine

-

Environmental monitoring during and after a mine closure

In developing countries and some less regulated areas, enforcement poses a challenge.

When mining companies need to obtain international financing, there are standards that companies will have to contend with, namely the IFC Performance Standards on Environmental and Social Sustainability, Equator Principles (EP), and other criteria for socially responsible investing. However, these organizations rely on self-regulation of mining practices.

The International Council on Mining and Metals (ICMM) is a coalition of nine mining companies which helps to improve environmental and social performance in the international mining industry. This council has funded conservationist groups, but some of these conservationist groups make land-use decisions without community input, leading to human rights controversies.

Open pit mine in Peru | Source: Source International

Open pit mine in Peru | Source: Source International

Organizations like the International Organization for Standards (ISO) and Ceres have a certification process for mines that involves inspections of mining procedures. Mines with good mining practices will be certified by these governing bodies.

However, the mining industry is largely unregulated in developing countries. Research by Michael John Bloomfield in his paper "Environmental management for extractives" outlines suggested strategies to help developing countries regulate mining, some of which include:

-

Engaging the services of standards agencies

-

Stressing ecological protection and poverty reduction through national income

-

Giving communities a stake in a mine’s revenue

-

Promoting transparency and participation in local communities

-

Enacting legislation for impact assessments and suitable land-use

-

Involving consultants to help with negotiations in order to reduce corruption

Community Regulations

The mining industry is a booming industry, however, few benefits are seen by local communities in mineral-rich regions. Organizing by NGOs and local communities called for new practices to include disadvantaged communities in mine planning—namely revenue management and full transparency.

Now, resettlements, community developments, and environmental impacts are mainstream concerns when international banks consider financing mining companies.

The Extractive Industries Transparency Initiative (EITI) is a global standardization body that requires the disclosure of information on the revenue chain from the government to the public, specifically on how they benefit local communities. They provide information on natural resource management and create accountability in the mining industry.

Entrance in the EITI is voluntary, although there are 56 countries that have adopted their standards. The EITI is accountable by a coalition of companies, governments, and civil society.

Problems with the Implementation of Standards

Implementation of mining industry regulations still has a long way to go. The EITI hasn’t decided whether or not to include artisanal mining which is practiced in about half of the countries who comply with the EITI’s standards.

There is also no consensus on how to handle no-cash payments from mining companies to national, local, and state governments.

Consulting with local communities | Source: Stantec

The EITI does not account for the disparity between mining companies and the local communities’ understanding of the mining industry. This creates problems when communities are negotiating with mining companies.

The EITI’s standards may limit negotiations beyond the minimum requirements, and mining companies may not be able to entertain suggestions to adapt standards to the communities’ specific needs. These roadblocks may undermine implementation of the EITI’s standards.

Governments, or other mediaries, should bridge the negotiations between mining companies and communities to ensure both sides are understood. Standards could be expanded to accommodate different countries' hurdles.