- NEWS >

- Introducing Colorization for the Elios 3: Bringing Indoor...

Introducing Colorization for the Elios 3: Bringing Indoor 3D Models to Life

Point clouds are powerful — but let’s be honest: they’re not always easy to read.

Whether you’re inspecting a sewer, analyzing rockfall damage in a mine, or documenting the inside of a combustion chamber, a monochrome LiDAR point cloud often requires training and experience to interpret. Many teams need to combine video, point clouds, and field notes to understand what they’re seeing.

Colorization changes that.

Launching in December 2025, Flyability’s new Colorization feature brings intuitive visual context to the indoor 3D models captured with the Elios 3. By generating a textured mesh and a colorized point cloud, teams can instantly grasp what they’re looking at — and extract insights that were previously hard or impossible to obtain.

And according to our beta testers, it’s not just useful. It’s a breakthrough.

Why colorization matters

Point clouds become easier for everyone to understand

Many people who receive Elios 3 data — managers, contractors, engineering partners — are not used to navigating point clouds.

By generating a textured mesh or a colorized point cloud, we add visual information that instantly grounds the model in reality. Walls look like walls. Stains look like stains. Markings appear where you expect them. Interpretation becomes faster and more accessible — even for people seeing the data for the first time.

As Daniel Jatko from LKAB puts it:

“The colorization feature makes the point cloud much easier to view than a normal point cloud — especially for clients that are not used to point clouds.”

This clarity reduces misinterpretation, avoids back-and-forth questions, and helps teams make decisions faster.

Watch the transition from point cloud to mesh to textured mesh with colorization

Measurements become faster and more precise

While our colorization algorithm isn’t as precise as photogrammetry, it dramatically improves the practicality of taking measurements in 3D. With textures applied to the mesh, users can visually locate the exact features they want to measure.

Ronny Boese, Managing Director at Cansol, shared how this has changed their workflow:

“We use the mesh for the condition assessment of the channels. It lets us measure exact lengths and dimensions directly in the mesh — something we previously had to determine by matching video with the model. That method used to be quite tedious.”

What once required manually comparing video timestamps is now a quick visual check inside the 3D model.

Measuring in the 3D model becomes much simpler

Critical details that LiDAR can’t capture become visible

Sometimes, the most important visual cues — wall markings, targets, stains, corrosion — don’t reflect LiDAR and therefore don’t appear in the point cloud. But they do appear in the textured mesh.

At LKAB, this turned out to be a key advantage:

“It becomes easier to point out fixpoint targets in the scan when you are not able to attach reflectors. The paint marks don’t show up in LiDAR, but in the textured mesh they’re clear.”

This makes colorization especially valuable for:

- Georeferencing underground models

- Tracking deformation or rockfall damage

- Identifying structural details

- Locating objects of interest more quickly

Colorization offers better clarity for details the point cloud might not capture

A better way to analyze damaged or complex areas

Geologists and rock mechanics teams often ask for more visual context when analyzing rockfalls or collapsed zones. While photogrammetry is technically possible indoors, it becomes extremely difficult to execute reliably in confined, dark, or dusty environments. Colorization offers a far more practical and consistent alternative for these scenarios.

One LKAB user noted:

“Our geologists want to see structures after a rockfall. They often ask for a colorized and really sharp mesh — something close to photogrammetry.”

Colorization gives them the context they need without the challenges of photogrammetry workflows in harsh environments.

Safer, faster data capture — with fewer on-site operations

For some organizations, colorization has the potential to replace workflows that currently require personnel to physically enter confined or hazardous environments.

Olivier Le Jort from SUEZ SEVESC, for example, explained that sewer mapping today often involves teams walking long underground sections with a handheld or mobile LiDAR system — a slow and sometimes uncomfortable process in tight and challenging networks. While SUEZ SEVESC is still in the testing phase, he sees strong potential for the Colorization feature to eventually streamline this type of work.

From his perspective, using the Elios 3 with colorization could offer several advantages:

- Faster data collection, since flights can cover long distances more quickly than walking

- Improved safety, by limiting the need for personnel to physically enter difficult areas

- Deliverables aligned with client expectations, thanks to textured meshes suitable for virtual walkthroughs

Although these insights come from early evaluations, they highlight how colorization could help operators rethink how they capture and deliver underground inspection data in the future.

A faster and safer approach to meet customer need

It makes sharing data dramatically easier

Customers increasingly expect colorized 3D models, especially as photogrammetry has made textured outputs common in outdoor environments. With the Colorization feature running on Flyability Cloud, sharing a colorized dataset becomes as simple as sending a link — giving stakeholders an immediate “I get it” moment.

Real users are getting hooked

Across industries, early adopters have shared enthusiastic feedback about the value — and business impact — of Colorization.

“A revolution for GPS-denied environments.” — medexon

“My customers literally said ‘wow’. It’s a revolution for GPS-denied environments. Even without following every tip, the results are impressive. And the workflow just works.”

“Highly valuable for precise measurements.” — Newmont

“The colorized rendering is highly valuable for precise measurements, like checking the spacing between bolts. It opens up new possibilities for field control and even incident reconstruction.”

“A game-changer for sharing data.” — Intergroup

“Colorization and textured meshes are game-changers for sharing our data. They make complex LiDAR much easier to understand, especially for clients unfamiliar with the technology.”

“This will really help our team understand asset condition.” — NYPA

“Having the ability to visualize assets in color is a big improvement over just the point cloud. The level of detail is impressive, even with some limitations.”

What colorization is (and isn’t)

We’ve built colorization specifically for fast, reliable, indoor 3D workflows.

This is not photogrammetry — and that’s by design.

☑️What it does

- Adds realistic texture and color to indoor 3D models

- Makes point clouds easier to interpret for everyone

- Enables faster, more precise measurements

- Improves communication with stakeholders

- Helps identify markings and structures that LiDAR alone misses

- Supports remote inspections and collaboration

❌What it doesn't do

- Replace photogrammetry for millimeter-level accuracy

- Reconstruct very small objects (<10 cm)

- Guarantee uniform texturing in occluded areas

Colorization is a visualization enhancement, not a metrology tool — but for inspection and asset documentation, it already delivers enormous value.

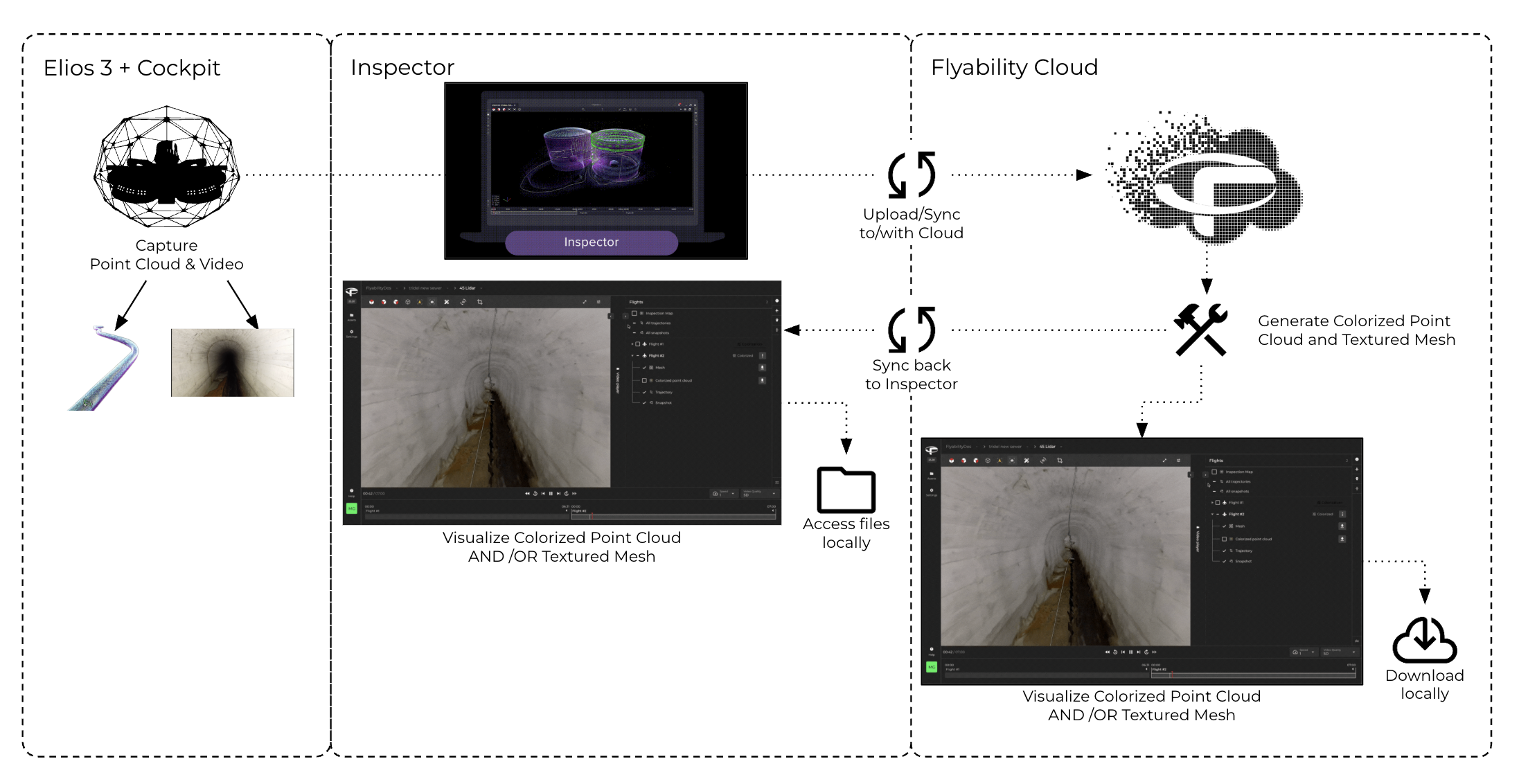

How it works

The workflow is simple:

- Capture your Elios 3 video and LiDAR as usual

- Upload the dataset to Flyability Cloud

- Process it in Flyability Cloud to generate a textured mesh and colorized point cloud

- View, share, or download the outputs in Flyability Cloud or Inspector.

No special training. No photogrammetry workflows. No tinkering with overlap or camera angles — just fly slowly and keep surfaces in view.

Data capture best practices

To get the best results:

- Dedicate one flight to colorization if possible

- Avoid letting the cage or UT probe enter the camera view

- Beware of very small features (<10 cm), which may not reconstruct well

- Expect texture drift or exposure inconsistencies in challenging environments

If the goal is ultra-precise crack detection or engineering-grade modeling, colorization is not the right tool.

If the goal is clarity, understanding, and speed — it absolutely is.

Cloud-powered, accessible to all

Colorization is a cloud processing feature:

- Cloud subscribers get unlimited colorization credits

- Free users get 10 trial credits to test the feature

- Viewing colorized results is free for everyone — even if processing was done by someone else

This makes it incredibly easy to share a colorized dataset with a colleague, manager, or contractor — they don’t need a paid subscription to explore the results.

Why you should try it

Colorization dramatically elevates the impact of your Elios 3 data:

- Faster interpretation

- Better communication

- More useful insights

- More convincing deliverables

And ultimately, more value is extracted from every mission.

If you rely on Elios 3 for inspections, this feature will very likely become a standard part of your workflow.

Ready to see it for yourself?

Colorization is a transformative feature we’ve built for the Elios 3 — and the best way to understand its impact is simply to try it.

👉 If you’re a Cloud subscriber, open any inspection and click the Colorize button next to a flight in the flight list.

👉 If you’re just testing, create a free Cloud account and you’ll receive 10 credits to try the feature on your own datasets.

Bring your indoor 3D models to life — and discover how much more your teams can see when the data speaks for itself.

Get started today! Head to Flyability Cloud