- Blog >

- What is Overburden in Mining?

What is Overburden in Mining?

Overburden is the rock or soil layer that needs to be removed in order to access the ore being mined. Overburden is also referred to as spoil or waste.

Overburdens are removed from surface mining and do not contain toxic components, unlike tailings, which is another type of underground mining waste. Interburden, a related term, refers to the material that lies between orebodies in subsurface levels.

overburden Definition

The strict meaning of overburden is anything—soil or rock—underground that stands between an object of interest and the surface.

-

In mining, the object of interest would be a mineral deposit (gold, silver, zinc, and so on).

-

In archaeology, the object of interest would be a historical artifact or ruin.

-

In other underground efforts, such as looking for underwater deposits of water, you could also loosely refer to the material (soil, rock, etc.) that covered the water as overburden, since it stands in the way of reaching the object of interest.

Seen through this lens, the definition of overburden is essentially just the "stuff" underground separating a person and the thing they want to extract from the earth.

Storing overburden

Storing overburden

What Type of Mining Is Associated with Overburden?

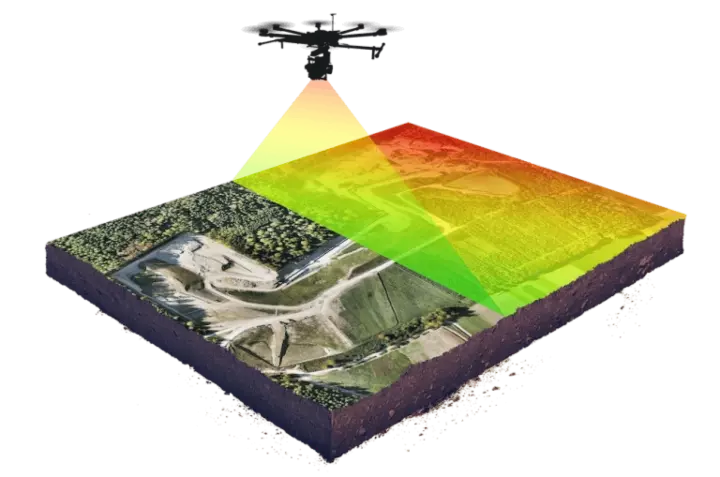

Surface mining, which is used to extract ore that is close to the earth’s surface, generates an abundance of overburden soil.

Here are the types of surface mining that generate overburdens:

-

Strip mining. Strip mining is a surface mining technique that removes thin layers of overburden in order to reach the mined ore. Overburdens in coal mining—strip mining is commonly used to extract coal near the surface of the earth, and it is a method that is used in the early stages of open-pit mining.

-

Open-pit mining. Open-pit mining is a mining technique that uses a drill and blast technique to create a large pit for mining. Dragline excavators are used to strip overburden from the mine.

-

Quarrying. Quarrying or quarry mining involves drill and blast methods to create pits. Miners then cut blocks of hard stone and create by-products like gravel, small stones, or sand. Quarrying is made accessible by open-pit mining and by strip mining overburden. This mining method is used to extract granite, marble, and other hard stones.

-

Mountaintop removal mining (MTR). Mountaintop removal mining is a surface mining method that involves the use of explosives to remove up to 120 meters of the surface from a mountaintop. Overburdens in coal mining—mountaintop removal mining is considered a safer mining method for coal removal since it avoids underground coal mining. Overburden soil is removed above the coal seams before extracting the ore.

Dragline excavator

Dragline excavator

Overburdens Management

Overburden management has a major impact on surface mining planning. Since overburden excavation starts immediately when mining operations commence, handling procedures need to be well planned for the removal and disposal process.

The overburden that is removed and the rate at which it is excavated depends on:

-

The orientation of the orebody (vertical or horizontal)

-

The required ore removal for productivity

-

The effectiveness of the offsite or onsite disposal processes, plus the area needed to support an influx of overburden stockpiles

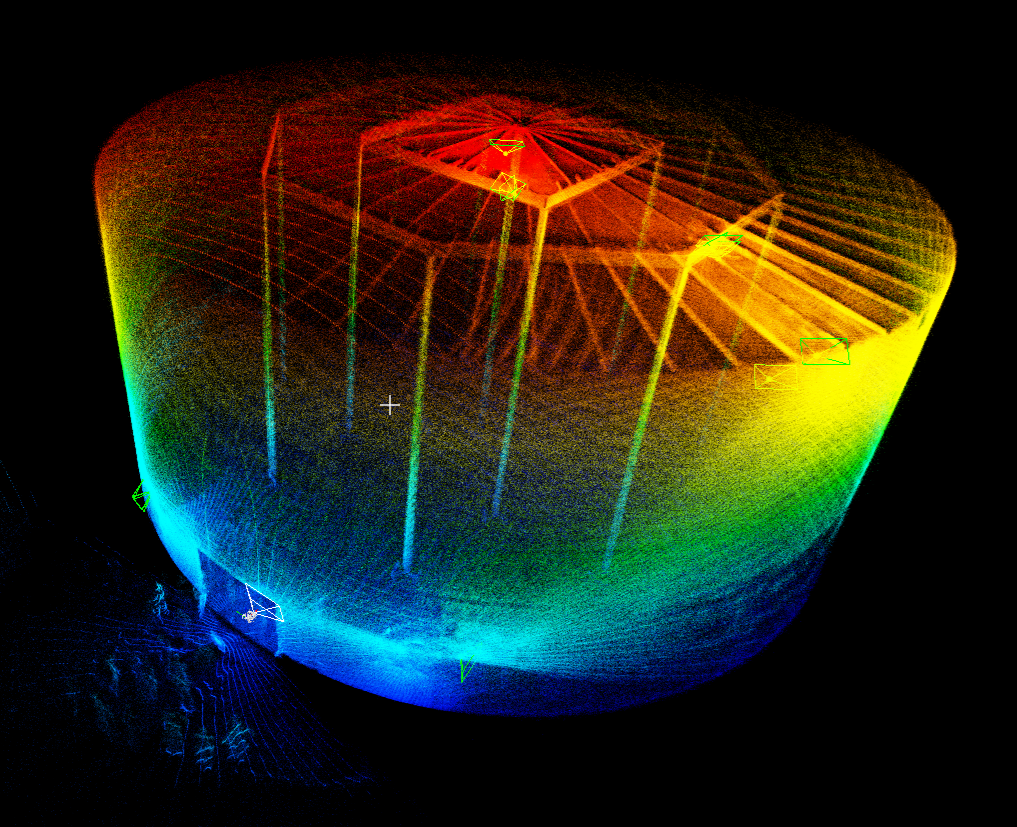

Overburden stockpile

Overburden stockpile

Overburden Removal and Disposal

When planning the overburden removal process, the following factors are taken into consideration:

-

Environmental features. This includes groundwater depletion and contamination, air pollution, sound pollution, groundwater interaction, flooding, erosion, water logging, seismic activity, landscape appearance, and the effects on natural wildlife and plants.

-

Geotechnical features. This includes the presence of fractured formations, moisture content, grain size distribution, ground strength, plasticity, bearing capacity of equipment and loads, and the stability of the excavated slopes—in order to prevent landslides, mudslide, and overburden rock falls.

-

Logistical features. This includes climatic conditions, including snow and rain patterns, accessibility to the site via roads, ramps, and railways, and availability of energy sources like electricity, fuel supply, and water.

Overburden handling should use the most technically sound and cost effective method. It is also one of the principal environmental concerns for the mining industry in regards to in-pit disposal and stockpiles, with the main concern being its interaction with surface and groundwater. Overburden mismanagement can deplete aquifers and also contaminate them with heavy metals.

Mine Reclamation

After a mine is depleted and no longer usable, the land enters a reclamation phase.

Reclamation involves rehabilitating the land to a more natural state. At times, the land is used for another industrial or municipal use during reclamation. In well regulated regions, detailed reclamation plans are typically required by mining operations in order for them to obtain a permit to start the mining process.

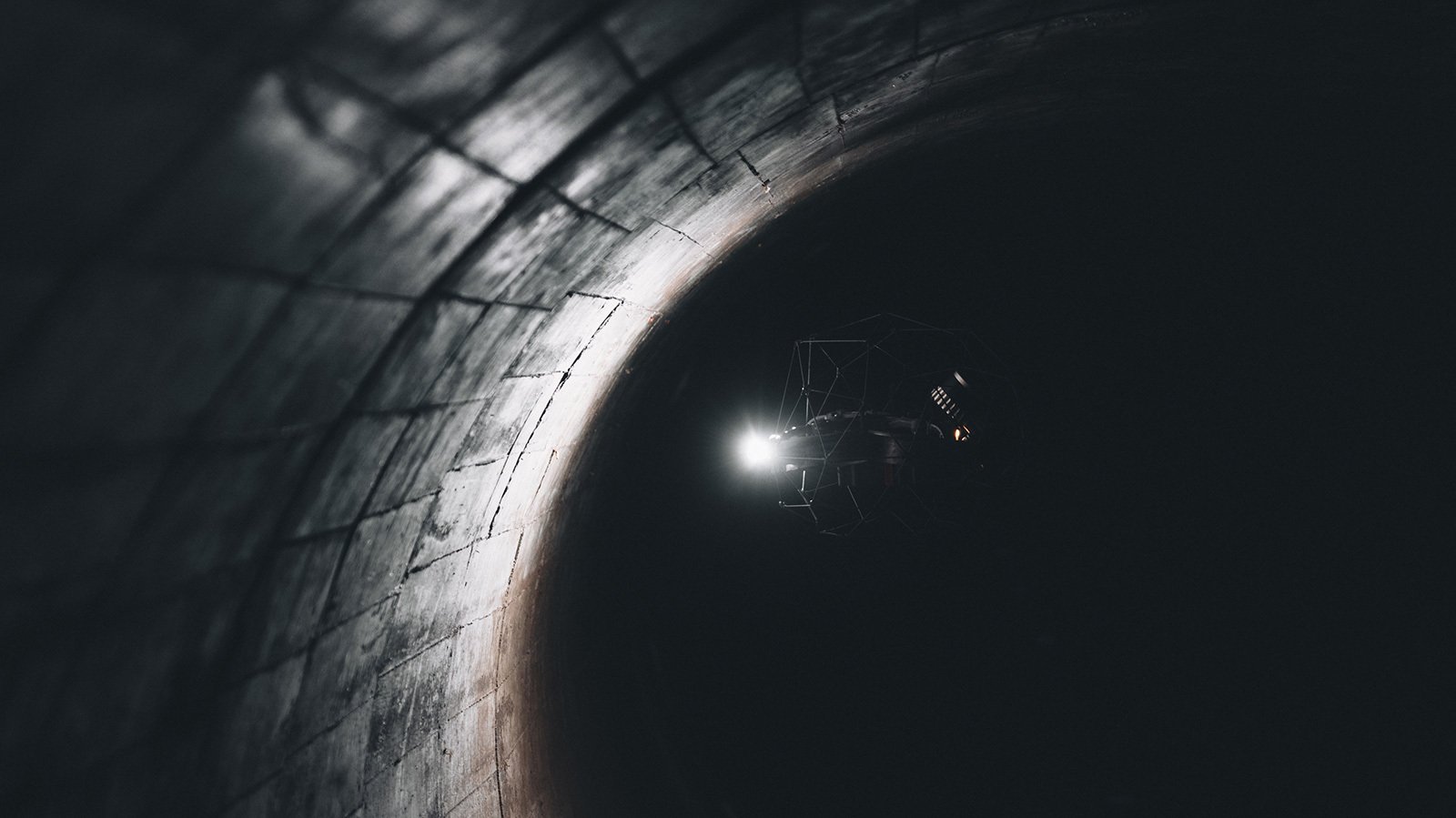

Mine reclamation

Mine reclamation

Mine reclamation can include creating a natural ecosystem by reforestation or by creating rangeland. Mines have also been turned into farms, strawberry fields, and even riparian habitats.

In the United States, the Surface Mining Control and Reclamation Act of 1977 (SMCRA) regulates the environmental effects of mining. The SMCRA established guidelines for existing and future mines, including permitting requirements, and also provided funding for the reclamation of abandoned mines.

The SMCRA regulates surface mining to make sure mining is conducted in an environmentally responsible manner. It also enforces reclamation during and after the mining process.