- Case Studies >

- Automating flight merging at a sugar refinery with the...

Automating Flight Merging At A Sugar Refinery With The Asset Management Extension

Benefits In A Nutshell

|

Access The Elios 3 safely provided access to 9,200 joints, with all the data compiled into a single 3D model. This allowed the site owner to view the condition of racks at all heights in a single point cloud. |

Speed The rack inspections would typically take weeks, but with the Elios 3 all inspection flights were completed in just 5 days. |

|

Accuracy With the Asset Management software extension, TEXO could create a digital twin of reality that showed the exact condition of racks, ready for analysis and maintenance planning.

|

Efficiency The Elios 3 completed the inspections in a fraction of the usual inspection time. The pilot used it to survey sections of racks at a time, so work could continue elsewhere at the same time, cutting unnecessary downtime. |

The assets and equipment inspected by the Elios drones vary hugely in size. In some cases, like small scale inspections, all of the data can be collected in just 1 flight. However, when working with greater assets such as pipelines or power generation sites, multiple flights may need to be conducted. In the past, merging these datasets could prove a challenge. Now, with Asset Management, it is possible to digitize assets and automatically merge data from multiple flights encompassing a single inspection.

Asset Management is Flyability’s latest addition to its product suite, launching in March 2024. It is an extension of Flyability’s own software, Cockpit and Inspector, which turns drone data into a consolidated view of an asset. The Asset Management software bridges the gap between flight-based data capture and asset analysis. It simplifies the Elios 3’s processing and reporting workflows by merging data from multiple flights into a single view of your asset.

Flyability partnered with specialized inspection service providers TEXO to use Asset Management to manage data collected at a food storage facility.

Challenges Of A Food Storage Facility Inspection

Food storage facilities are typically large structures with specific organization systems, which can include racks in a warehouse. Inspecting the condition of storage material at these types of facilities presents various challenges.

- Walking around is very dangerous as stored material can fall from the racks and cause injuries if people are underneath, which is why remote inspections are favorable.

- Nothing looks more like a rack alley than another rack alley and such storage facilities contain hundreds of these alleys.

- Each rack has multiple points of control that must be inspected, which makes the entire process time consuming and prolongs potential downtime.

An ideal solution for inspecting a food storage area must be able to gather all of the necessary data, provide results that differentiate between similar-looking locations, and enhance the safety of inspectors.

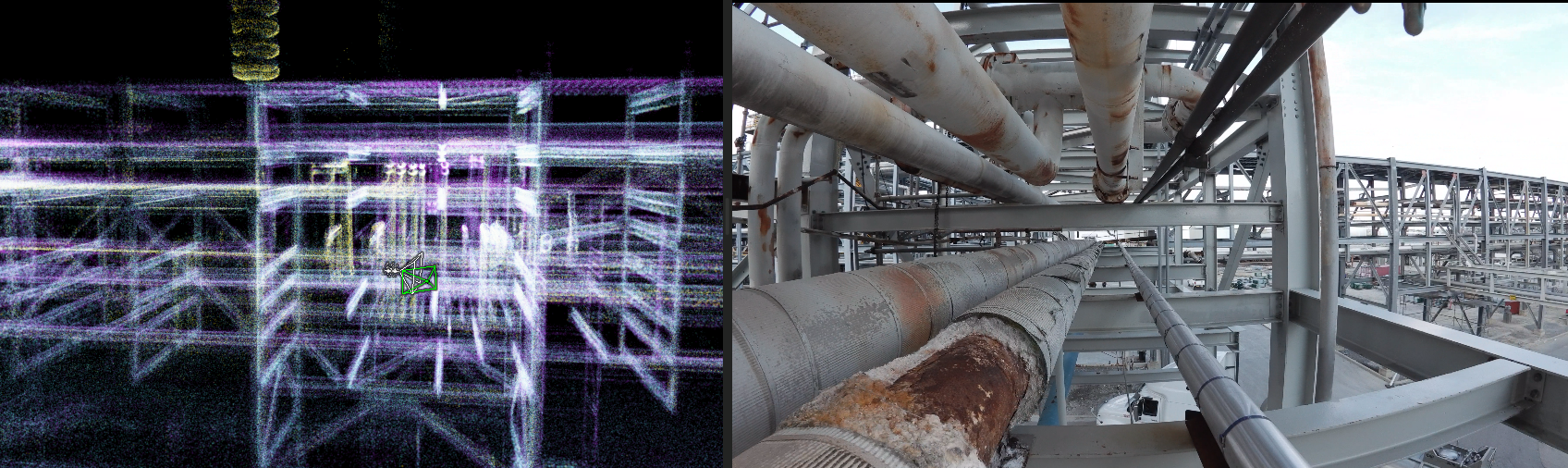

The Elios 3 flying between the racks to conduct inspections

How An Inspection Service Provider Turned To The Elios 3

TEXO works on precision engineering and surveying projects, using their expertise to deliver results for construction, asset management, and complex projects. With projects including oil rig inspections and powerplant surveys, they are known for producing quality results even with challenging inspections.

In 2023, TEXO was contracted to inspect racking systems at a sugar refinery. The racks had been in place for 30 years and the client needed to determine if the racking would need a full replacement or if only minor repairs were required. TEXO was asked to conduct a full condition assessment. The client wanted a final complete point cloud with all of the data merged but did not believe it was possible. However, TEXO beta-tested the Asset Management extension for Inspector and Cockpit and took this as the opportunity to use the new software.

There were 9,200 racking joints spread over 5 rows inside a warehouse that needed to be inspected. In the past, an inspection would require prolonged downtime as rope access was set up, or a mobile elevated work platform (MEWP) was used. It can also be difficult to localize points of interest with this method as the environment is very monotonous. Using drones represented an attractive alternative with greater access, improved safety, and shorter downtime.

Using The Elios 3 And Asset Management Extension

The TEXO team arrived at the site and used their Elios 3 drone to survey the area. The Elios 3 was the ideal tool for working in this cluttered indoor space, where other drones could risk being damaged by the pipes and complex structure. In addition, the drone’s live map made it easy to navigate even when the environment looked very similar.

In the past, an inspection of this nature would take weeks to cover all 5 rows in the structure. However, the Elios 3 could inspect an entire lane per day while other lanes remained in operation. This meant that there was minimal downtime for the site and all inspections were completed in just 5 days. This removed the need for hazardous work at height via scaffolding or rope access. The workflow involved 5-8 flights per side of the racking lane. As the pilots worked, they marked points of interest for the refinery owner to examine later.

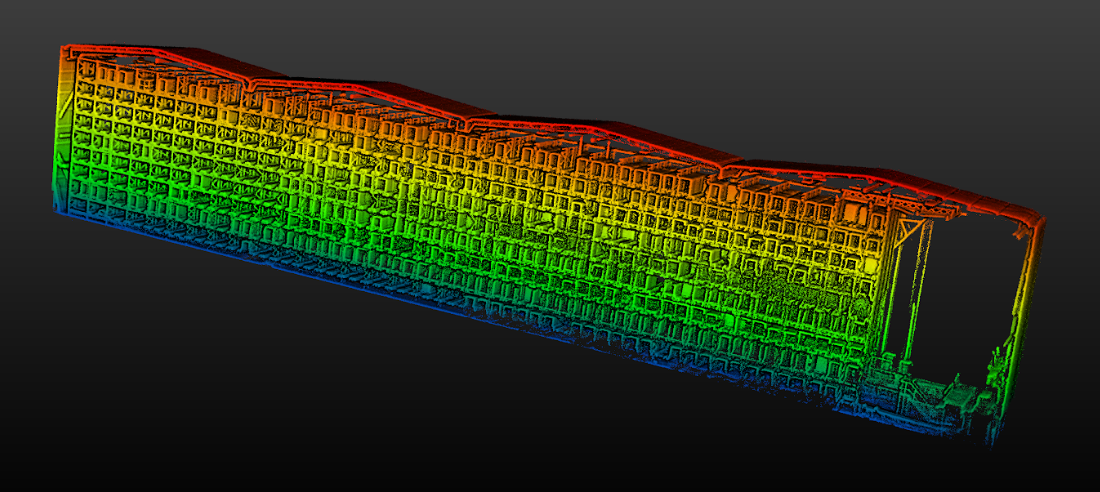

All of the sugar racks were clearly visualized through the LiDAR point cloud

The client specifically asked for one complete point cloud they could inspect afterward. This is where the Asset Management Extension became critical to the mission's success. The flights of each racking lane were merged within the Asset Management software as the data was captured. At the end, TEXO provided one clear, final point cloud without any needing to do any post-processing. While flying, the pilot could use Cockpit to see the points of interest captured in the previous flights which made it possible to track the completeness of the data capture process. In the final point cloud, the points of interest captured in each flight were clearly shown, making it easy to inspect the entirety of the data collected without additional processing or transferring data between point clouds.

Without the Elios 3 and Asset Management software, this project would have taken weeks from data collection to data processing and merging. Instead of spending hours aligning the different point clouds, Asset Management made quick work of combining lots of information from multiple flights.

The Benefits Of Asset Management With Flyability

The Asset Management extension provided exceptionally clear results. The client was so impressed with the visualization that they requested access to Inspector so they could interact with the data themselves. Every joint in the warehouse had been recorded and logged, providing the client with not just a condition assessment but also a permanent log to be used as a reference point for the condition and deterioration of the racks.

The warehouse was visualized in one final model that seamlessly merged all of the Elios 3's inspection flights

The Elios 3 provided a safer, faster alternative to traditional inspection methods whilst the Asset Management extension empowered quick data processing and analysis. The key benefit of this software was the comprehensive 3D point cloud that included all points of interest and information captured from over a dozen flights. It made it easier for the TEXO team to showcase their results and set themselves apart from competitors with fast results that include a high level of detail.

The improved reporting, faster data processing, and high quality of results TEXO achieved with Asset Management all contribute to their continued use of this software, as well as streamlining their post-processing workflows. Asset Management is the next step in bringing simplicity to digitzing large and complex assets.

DISCOVER ASSET MANAGEMENT WITH FLYABILITY

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)