- Case Studies >

- How can the Asset Management extension reinvent your Elios...

How Can The Asset Management Extension Reinvent Your Elios 3 Workflows?

If you’re familiar with drone data capture, you’ll know that the usual way drone pilots capture data is flight by flight, where one flight is one set of data. However, this is not the way asset managers look at data. Asset managers are interested in viewing an entire asset and assessing its condition based on the last inspection. This is where the new Asset Management software extension for Cockpit and Inspector (the Elios 3’s piloting app and processing software) comes in to bridge the gap between drone-based data capture and proper asset management. In this article, we will explain the improvements that the Asset Management software extension brings to your workflows and why this will drastically change the way you look at your data.

Presenting Clear Data To Asset Managers

Asset managers use inspection data to understand how their asset is aging over time and inform plans for preventive maintenance or repairs. It is vital for inspectors and inspection companies to offer asset managers a comprehensive view of their asset. Today, this involves data that is categorized by the date of inspection and often presented as a digital twin of the asset. This digital twin means the data is readily available, easy to navigate, and enables asset managers to pinpoint areas of interest in context with the overall asset - and wider site processes.

But asset managers are not the only people who greatly benefit from this type of data organization and presentation. A repair crew or personnel charged with further investigating a defect find it extremely useful to be able to look at a digital twin of an asset and its associated information all at once. This facilitates planning for access, ordering of parts, or estimating labor and costs.

In the digital world we live in, digital twinning and asset management tools are becoming the standard across industry. Thus, the tools in the inspector’s toolbox must conform with this way of looking at asset data. During an inspection, drones naturally segment data into flights, and so it has been the case for the Elios 3 from Flyability so far. With the introduction of the Asset Management extension for Cockpit and Inspector, we’re changing this to organize Elios 3 data in a way that better meets the expectations of modern asset managers.

How Does The Asset Management Software Extension Work?

The new software extension is a part of the entire inspection process, from flight to post-processing. The simplest and most efficient way to make sure data is organized the right way is to categorize it during data capture. With the Asset Management extension enabled, Elios 3 pilots can create a new asset, start a new inspection in an existing asset, or continue an existing inspection every time they get ready for a new flight.

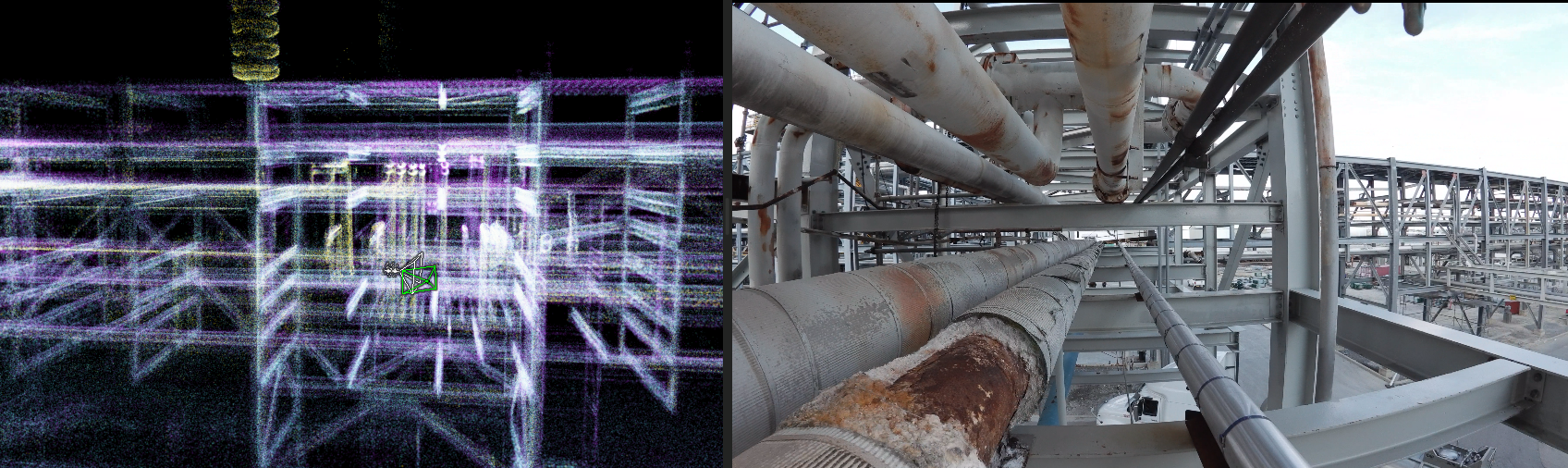

The Asset Management extension enables pilots to see layers of data from previous flights

Beyond this categorization, the data must be spatially organized in a single frame of reference across flights to facilitate a clear view of a single digital twin. For that reason, the Asset Management extension brings a new concept to the data capture workflow of Elios 3 called relocalization. When performing additional flights in an asset where you’ve flown before, you will start your inspection with a historical map of the asset which results from all inspections previously performed. Before starting the flight, the drone will perform the relocalization process, which consists of aligning its current position within the historical map. As a result, all data captured during the flight will be automatically and precisely localized within the historical map of the asset.

With this approach, pilots will complete their inspections with the data already organized per asset, making it easier to analyze and manage.

What Other Benefits Arise From Using The Asset Management Extension?

When performing an inspection, there’s nothing more frustrating than getting back to the office to realize that a part of the data is missing. Beyond the advantages mentioned above, the Asset Management extension enhances the experience of the pilot by persistently displaying previously made maps and Points Of Interest across flights during an inspection. This allows pilots to accurately track the completeness of a job and make sure they always leave the site with a complete data set.

In the future, the Asset Management extension will allow users to selectively load previous Points Of Interest in addition to the historical map allowing pilots to come back to certain areas of concern and repeat inspections time and time again.

The Asset Management extension enables pilots to see Point Of Interests from previous flights

How Can You Benefit From Asset Management With Flyability?

To benefit from the extended functionalities of Asset Management, you need an Elios 3 Premium Software Subscription. This subscription is included for 3 years with every Elios 3 Premium and Enterprise drone package and can also be purchased separately for one year at any point in time. A free trial can also be started for 30 days once for every Elios 3 that does not already benefit from a Premium Software Subscription. If you are interested in learning more about the Asset Management extension or seeing it in action, visit the Asset Management webpage or contact us.

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)