- Case Studies >

- DroneUp Saves 700+ Hours in ABS Tank Inspection with Elios 2

Droneup Saves 700+ Hours In ABS Cargo Tank Inspection With Elios Drone

DroneUp used the Elios 2 for a cargo tank inspection on a warship, saving over 700 hours of work and cutting the cost for the inspection in half.

Benefits In A Nutshell

|

Savings The costs for the cargo tank inspection were cut almost in half by using the Elios drone instead of manned entry into the confined space. |

Speed Time for the inspection reduced by over 90%. Original projection for the inspection was 800 hours—using the Elios 2 brought this down to around 50 hours, for an overall time savings of well over 700 hours. |

|

Safety No confined space entry or use of flotation devices in a confined space required. This drastically reduces the risks to inspectors. |

Data Quality The Elios drones can provide close visual data for a cargo tank inspection the level of detail required by class societies such as ABS. |

Introduction

The American Bureau of Shipping (ABS) is the classification organization that sets inspection standards for a wide range of maritime vessels, including warships hauling freight, which are used to resupply other ships while they’re underway.

Like most industrial assets, warships must be inspected regularly to ensure that they are still fit for use.

In addition to the standard annual surveys, a vessel’s inspection cycle also includes a Special Periodic Hull Survey every couple of years.

This Hull inspection involves a more in-depth set of inspection procedures that assess a more comprehensive scope of the vessel, including the subsurface conditions of its ballast and cargo tanks.

The warship in which DroneUp conducted inspections with the Elios 2

After decades of overseeing these surveys, the government agency that manages these warships is able to source expert teams local to the vessel through a well-known bill of materials (BOM), manpower expectations (800 hours), and services defined according to historical tank inspection data.

This information is templated and published in a Request for Proposal (RFP) seeking competitive bids from competent providers to support the Ship’s force and Port Engineer, expected man hours, and the activities necessary for the scope of service.

Once the RFP is public inspectors can submit bids on the work, and typically the best bid from an established inspection services company will get the job.

Planning A Cargo Tank Inspection

The approach to the cargo and ballast tank inspections that is outlined in a typical RFP delineates requirements and deliverables that meet standard operating procedures (SOP), defined according to current industry standards.

This traditional model uses proven methods that have been employed for decades to conduct these surveys. For the warship in question, the vessel was scoped for 800 man-hours to complete the required inspection.

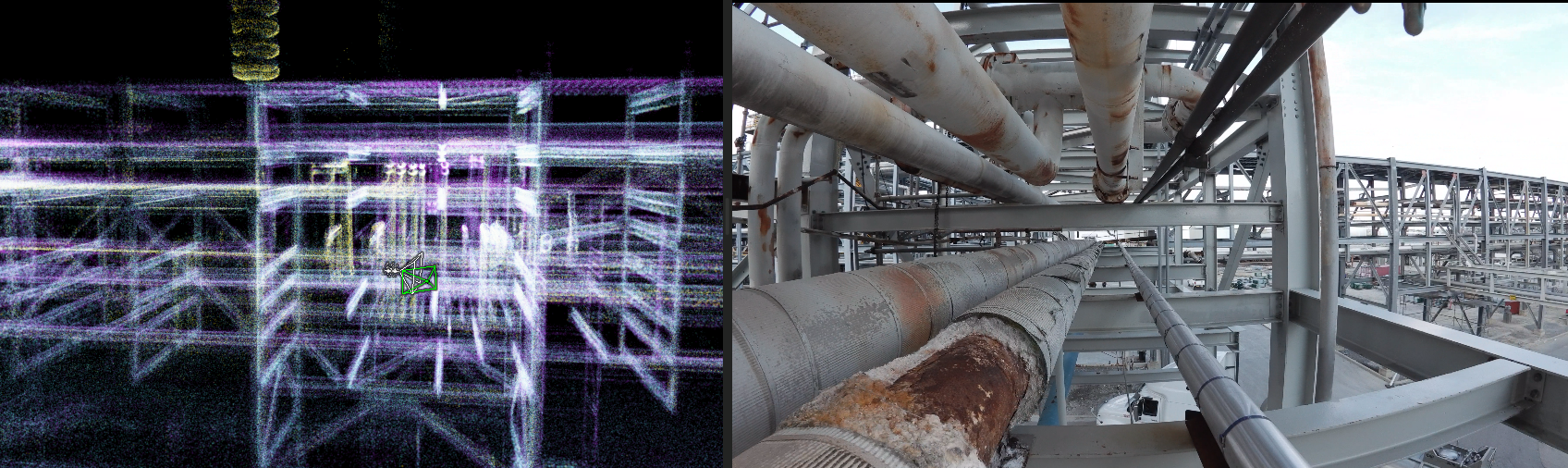

A picture taken inside one of the areas being focused on for the cargo tank inspection

Here is the traditional model inspectors use for completing these cargo tank inspections:

⦁ Fill the tank. Inspectors/supporting personnel empty each tank and perform the cleaning and drying protocols as appropriate for the tank’s type of contamination. Once the required airing-out time has been reached, the tanks are then filled with water.

⦁ Get into the raft. Two inspectors climb through the open hatch and into the tank’s enclosed space, settling onto a floating inflatable raft. Armed with a flashlight and camera to take pictures at will, one inspector is tasked with maneuvering the raft safely within the tank while the other is charged with performing the close-up visual assessment of each surface area of the tank.

⦁ Inspect at the first water level. Moving around the edges of the tank, the inspectors use their flashlights to visually inspect the walls and surfaces that are visible within the tank. For a surface to be considered inspected, the inspector must be within arm’s reach of it. Given that some surfaces can’t be reached, this means that the entire tank never gets fully inspected.

⦁ Lower the water level. After completing a visual inspection at the starting water level, a certain amount of water is released from the tank.

⦁ Inspect at the next water level. Inspectors then float around the perimeter of the tank again, conducting their visual inspection by flashlight with the help of the two people standing outside, pulling ropes to position the raft.

⦁ Repeat until finished. This process is repeated until the water is completely emptied from the tank and the inspectors have conducted a visual inspection of all the tank’s surfaces that they can see this way.

DroneUp did not know it at the time of submitting its bid, but the U.S. agency that put out the RFP already had initiatives underway to explore alternative means to this time-consuming, labor-intensive, and hazardous operating cargo tank inspection procedure. Moreover, strategic objectives were starting to form at the agency.

In its bid, DroneUp personnel proposed a unique approach to the inspection that they believed could significantly reduce the projected 800 hours for the inspections.

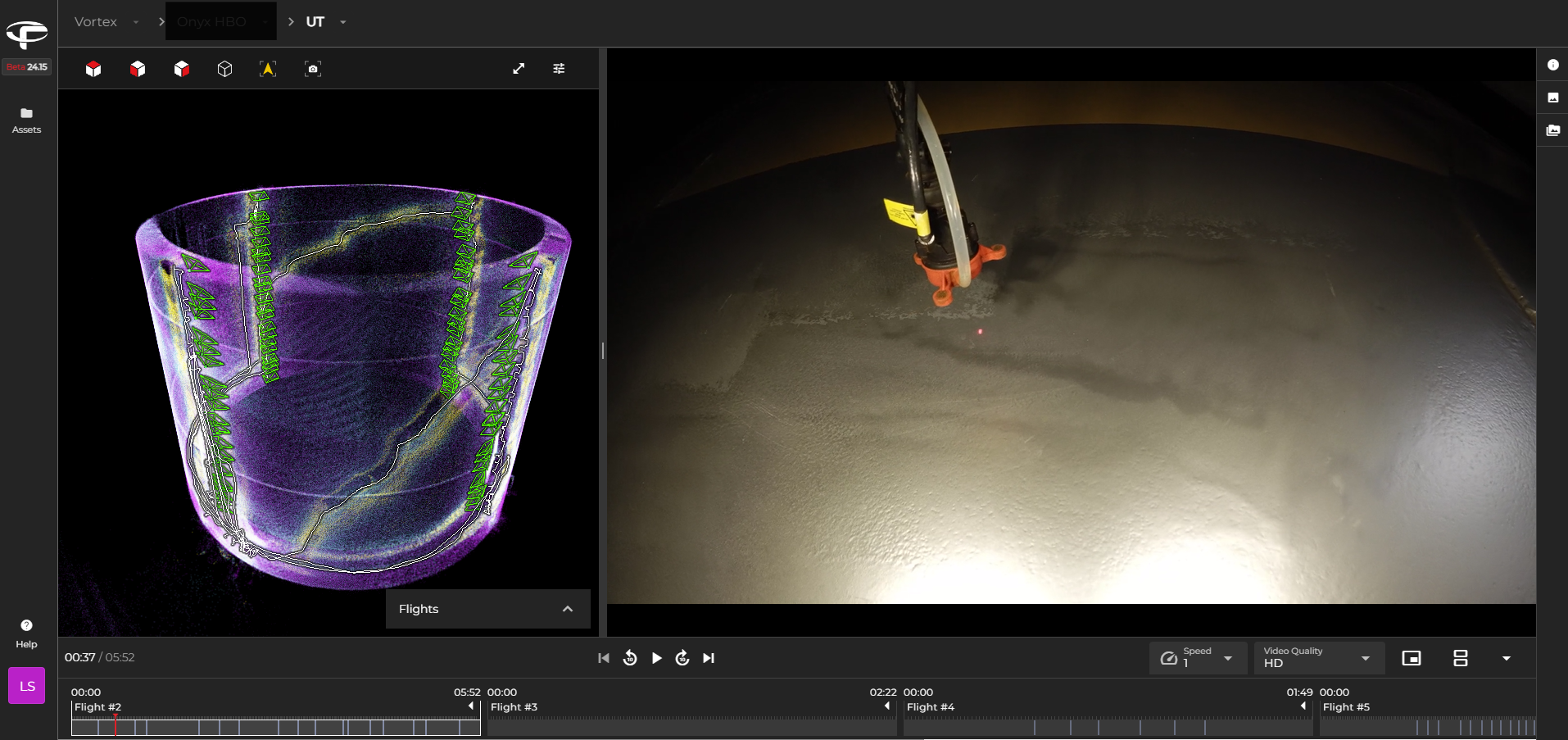

The Elios 2 flying to collect inspection data. Since this mission, Flyability has released the Elios 3 along with a UT payload that can gather ultrasonic thickness measurements, laser scans, and visual data simultaneously.

By using the Elios indoor drone, the team at DroneUp believed they could cut the time needed for the ship’s cargo tank inspections by over 90%. They submitted a bid that proposed testing their approach and comparing it to the results achieved with the traditional life raft method.

After review, DroneUp’s processes and the quality of their past work they accepted the bid, and DroneUp scheduled the inspection.

Results Of The Cargo Tank Inspection With The Elios Drone

The ballast and cargo tank inspections on the warship were a big success.

Cleaver and the DroneUp team were able to prove the claims they’d made in their bid—namely, that using a drone to inspect a warship’s tanks could make the entire process faster, cheaper, and safer.

The Elios 2 flying inside a cargo tank

Here are the specific benefits they demonstrated:

⦁ Savings. DroneUp used the Elios 2 to cut the overall cost of inspecting the ship’s tanks in half.

⦁ Speed. The time needed to conduct the tank inspections with the Elios 2 roughly matched the projections Cleaver had made in her bid, bringing the hours needed down from 800 to around 50, for a total time reduction of over 700 hours.

⦁ Safety. Using the Elios 2 to inspect the tanks meant that no one had to enter a confined space to collect visual data or to support those collecting visual data. It also meant that inspectors didn’t have to use a flotation device inside a confined space.

⦁ 100% coverage. Using the traditional approach, which requires that inspectors be within arm’s reach of a surface for it to be considered inspected, doesn’t allow for full coverage because not everything can be reached from the life raft. The Elios drone ensured 100% coverage within every tank because it could fly close enough to all the surfaces to gather high quality visual data.

⦁ Frequency of inspections. Given the speed and efficiency of using the Elios 2 for these tank inspections, MCS may inspect its tanks more frequently in the future, which could help improve the overall longevity of the tanks and the ship itself.

The DroneUp team watches the Elios 2's live feed while flying during the cargo tank inspection

The Future Of Drone-Enabled Cargo Tank Inspections

Given the success of the tank inspections Cleaver performed on the warship, and her new ABS-certification to use drones in these types of inspections, DroneUp is now planning to do many more cargo tank inspections with the Elios 2.

In addition to collecting visual data, DroneUp has been working to create digital twins of the maritime assets it inspects, in order to provide the highest quality outputs for its clients.

Norfolk is a big shipping town. Since Cleaver’s ABS inspection, word has spread about the success of DroneUp’s efforts on the warship.

With the high demand for this type work and DroneUp’s impressive results, it looks likely that Cleaver and her team will be using the Elios 2 not just for tank inspections on warships, but for lots of other maritime inspections in the near future.

.png)