The revolution of power plant inspection drones

Power plant assets like boilers, pipes, and chimneys are under constant stress and need to be regularly inspected to avoid unwanted downtime. Inspections however often take place in confined and hard-to-reach areas which can be dangerous and costly. The Elios 3 is a power plant inspection drone created to improve inspection safety and efficiency by up to 90%, saving the plant significant money and time.

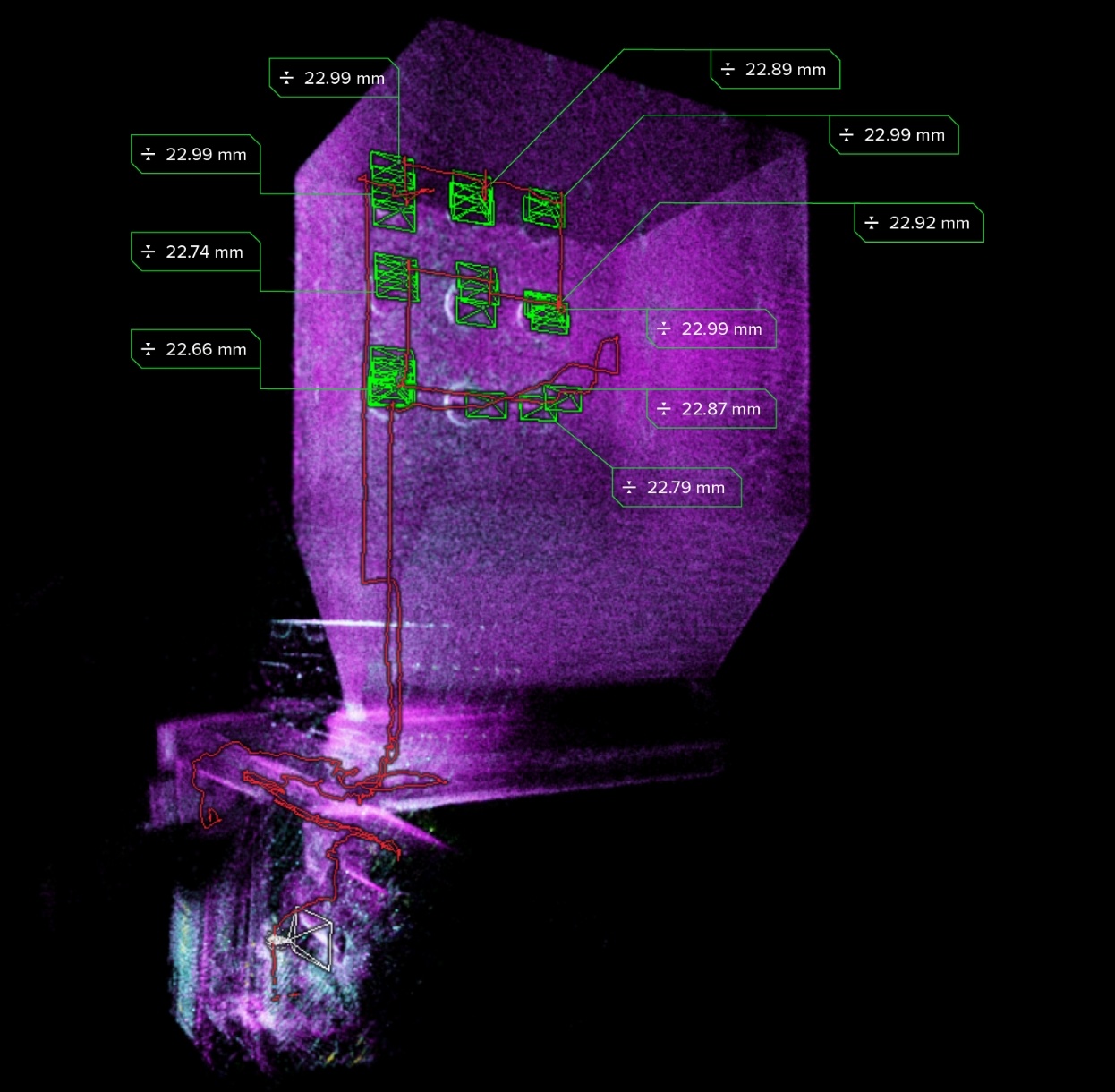

The Elios 3 drone is able to collect high-quality visual data thanks to its 4k camera and accurate UT measurements thanks to the UT payload. Advanced LiDAR technology also allows the drone to precisely localize all measurements within the asset's 3D model.

-

Image represents: Software output and 3D model with UT measurements captured by the Elios 3 UT while inspecting a boiler.

The benefits of adopting power plant inspection drones

Safety

Keep workers out of harm’s way by using drones to perform inspections in confined and hard-to-reach areas.

Efficiency

Get real-time data inside an asset without scaffolding or rope access and use it for proper service planning.

Costs

Reduce inspection costs by up to 95% and conduct critical inspections while minimizing maintenance costs.

Access a wide range of applications for power generation inspection drones

Capture every corner of the most confined assets from a safe location

-

.jpg)

Boiler inspection

Read moreSee how drone boiler inspections are transforming power plant inspection and maintenance processes by improving safety, speed, and data quality. See what Life Span Assessment Team Lead and experienced Drone Operator, Filip Schmidt, has to say about the role of drones for UT boiler inspections.

-

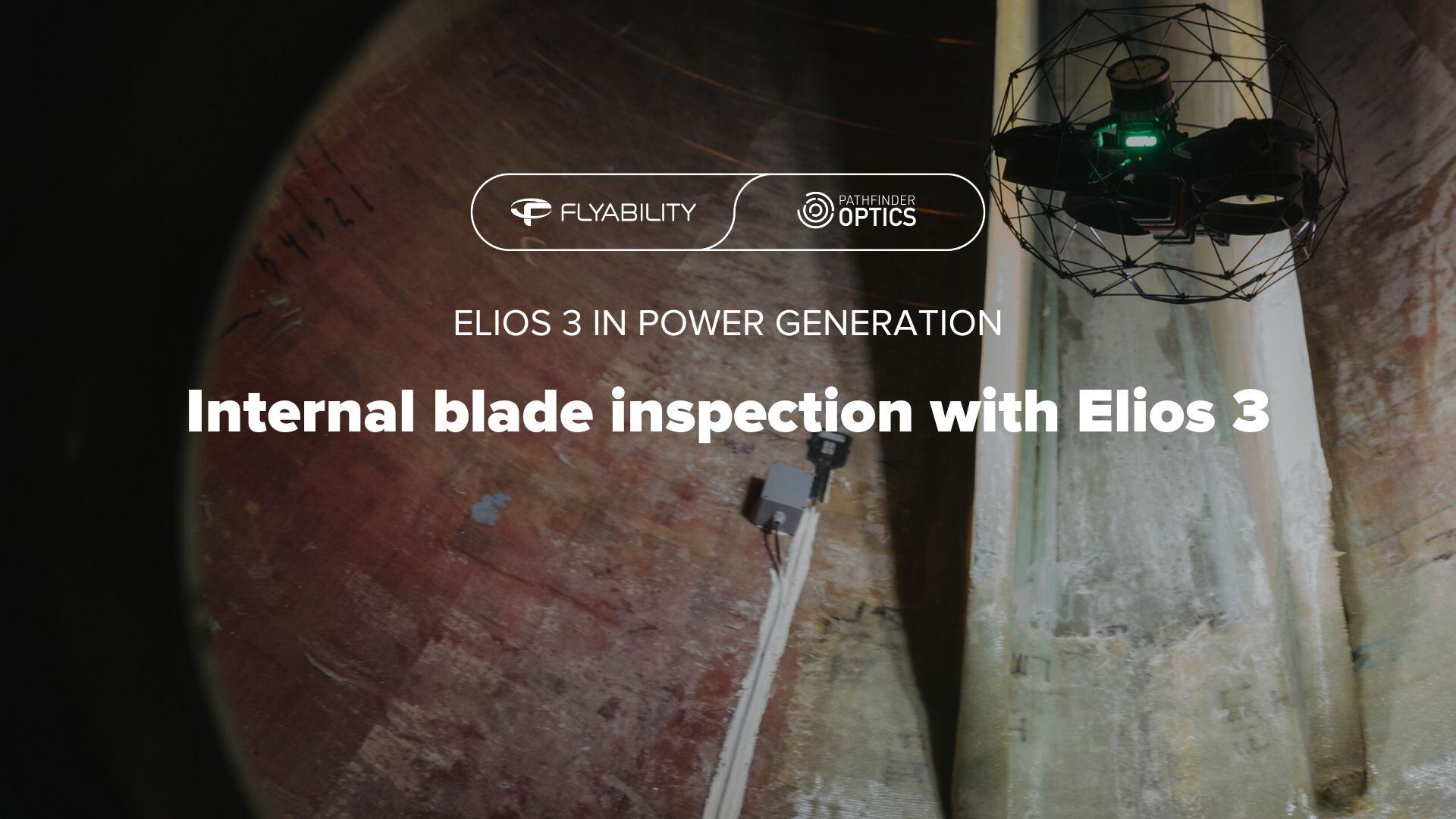

Wind turbine blade inspections

Read more90% of wind turbine blade defects can only be detected from the inside. Missed defects can damage the motor and cost up to $ 1M to repair. Now, with wind turbine drones, you can gather key data faster and more safely than ever before and identify defects easily.

Internal blade inspections are a fundamental part of wind turbine maintenance operations. Unreported cracks, blisters, or fiberglass buildup can lead to reductions in energy production and serious issues with the blade and the motor. By deploying the Elios 3 drone, it is possible to get inside a tower and complete an inspection of all 3 blades within 2 hours. All you need are two people and the Elios drone. Inspect two blades at a time and push the drone 30% further than a human would be able to go, create digital twins, use the LiDAR to measure cracks, and have the turbine back in operation in no time. This use of wind turbine drone inspections saves time, provides previously unavailable data, and reduces confined space exposure.

-

-1.jpg)

Stack inspection

Read moreSave up to $50K on a single inspection by flying a drone from the bottom to the top of a chimney to collect visual and UT data and safely assess the condition of the asset. Thanks to the Elios 3 UT you will be able to avoid work at height and inspect the whole chimney in under 2 hours, compared to 2+ days with traditional UT methods.

-

.jpg)

Penstock inspection

Read moreAvoid sending people into confined spaces like penstocks by using a remote inspection drone instead. The Elios 3 can capture high-quality visuals, UT measurements, and LiDAR scans in GPS-denied environments. Detect cracks and potential damages or signs of corrosion and make informed decisions for maintenance planning. Perform the full inspection in under 2 days (compared to over 7 days with ropers) and save $80,000 on inspection costs, plus anywhere between $100,000 and $500,000 in reduced downtime.

-

Boiler inspection

Read moreIn just 8 hours (compared to 9+ days on average with traditional methods), use a drone to remotely identify any damage inside a boiler, perform a full UT inspection of the boiler and superheater pipes, and plan for maintenance. Save over $200,000 on scaffolding and labor costs, plus an additional $250,000 in reduced downtime costs. With Inspector 5, our companion software, defects and UT measurements are precisely localized in the 3D map of the asset and fully documented, reviewable, and easy to share.

-

Wind turbine inspection

Read moreInspect wind turbine blades 4x faster and avoid sending rope access technicians inside the blades by using the Elios 3 drone instead. 90% of blade defects can only be found from inside the blade, and the Elios 3 with its 4K live video feed is the perfect tool for the job. Check the flange connections and bolts in the tower or inspect the blades for cracks, loosened bolts, and other damage. Use the LiDAR to overlay external and internal blade inspections and take advantage of the UT payload to scan the tower and underground/underwater structures for rust and corrosion without having to send a person.

-

Cooling tower inspection

Read moreInspect the cooling tower fill structure safely from the ground, without the need for scaffolding or man lifts, saving you thousands in the process. Perform a full inspection in under 2 days, compared to 10+ days with traditional methods, and localize any defects or damaged supports within the 3D model of your asset.

-

.jpg)

Underground water pipe inspection

Read moreIdentify threats to critical assets by performing visual inspections & LiDAR mapping inside vertical pipelines (from 80 cm in diameter). Reduce forced outages through preventative maintenance plans and get 100% data coverage inside out-of-reach areas. With the Elios 3, collect actionable insights including high-quality photos and video & 3D maps with centimeter accuracy.

See how Elios 3 UT helps our clients save time, money, and stay safe

.png?width=128&height=64&name=Co-branded-logo_Flya%20-%20VZU%20Plzen%20(1).png)

“

“Elios 3 is a platform. It's an inspection tool and a platform. So basically, you can do visual, ultrasonic (UT), and thermal inspections with this tool. The main applications for the Elios 3 in power generation are very wide.”

Filip Schmidt

Life Span Assessment Team Lead at VZU Plzen

They already use our products