- Case Studies >

- How Much Radiation Can the Elios 3 Handle? Testing at a DoE...

How Much Radiation Can The Elios 3 Handle? Testing at a DoE Site

The Idaho Environmental Coalition under contract with the Department of Energy exposed the Elios 3 to 10,000 R/h of radiation. Here’s what happened.

Benefits In A Nutshell

|

Safety Remote access via the Elios 3 was the only safe way to gain access to a designated area, so the drone was tested to determine the level of radiation it could withstand ahead of the mission. |

Research The Elios 3 was being used by the Idaho Environmental Coalition to help assess the best way to manage highly radioactive waste. Testing the drone's capabilities under high radiation would inform the mission planners. |

|

Data Quality Both the Elios 3's camera and LiDAR payload were able to continue to provide data under iradiation alongside other key features including transmission, lighting, and gimbal. |

Access If successful, this test would prove that the Elios 3 was able to enter the hazardous environment without any human exposure, eliminating risks from radiation exposure.

|

This article is part of a series detailing how the Elios 3 is being used in a project led by the Idaho Environmental Coalition (IEC) under contract with the Department of Energy (DOE)) to develop a safe method for removing several hundred cubic meters of highly radioactive waste from underground storage bins in Idaho. The name of the project is the Calcine Retrieval Project (CRP).

Key points:

- The Elios 3 was tested for radiation tolerance to determine whether it could operate successfully in a 1,000 R/h field and whether it could continue to operate with an accumulated dose of 1,000 R. The Elios 3 met both objectives.

- The Elios 3 went on to exceed the minimum requirements of the test, operating successfully in a 10,000 R/h field and continuing to function after an accumulated dose of approximately 4,000 R.

- The drone’s visual camera, LiDAR sensor, and all its other component parts such as transmission, lighting, and gimbal worked while irradiated as well.

The Challenge: Flying A Drone Inside An Irradiated Vault Buried In The Earth

Under contract with the DOE, the Idaho Environmental Coalition (IEC) has been tasked with finding a safe way to remove a large amount of radioactive waste stored underground over 60 years ago and move it to a new storage location. The nuclear waste is called calcine, and it is a solid, granular material produced from spent nuclear fuel.

As a first milestone in the project, the IEC had already developed a unique method to remove the calcine that involved drilling holes through the concrete roof of the vault housing the calcine storage bins, then using robotics to weld access pipes to the bin tops and cut holes into the bins allowing for the calcine to be pneumatically sucked out.

Before employing this new approach, the IEC first needed to better understand the environment in which it would be operating.

To do this, the IEC knew it would have to identify all obstructions within the vault above the bins such as conduit, support beams, and vent lines to determine whether these obstructions would prevent them from installing the extraction equipment. Further, it didn’t just need pictures or video of these obstructions—it needed 3D models.

After in-depth research, the IEC determined that the best solution for creating 3D models inside the vault was Flyability’s Elios 3 indoor drone.

The Elios 3 was chosen because it is designed to maneuver in confined, cluttered spaces and because it carries a LiDAR sensor, allowing it to collect precise data for 3D mapping.

After selecting the Elios 3 only one question remained—can the Elios 3 handle the radiation?

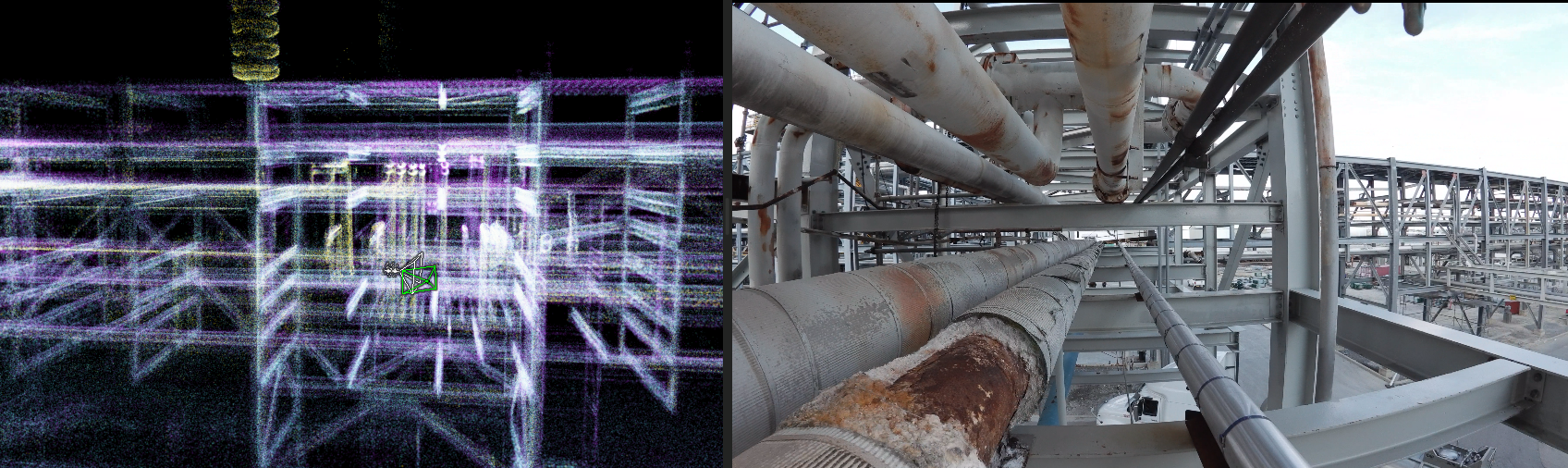

The Elios 3 in the midst of being iradiated

To gather all the data needed to make a 3D model of the interior of the vault, the Elios 3 would need to fly to each of the four corners of the vault, a process that could require up to four separate 6-minute flights. During this time, the drone would be exposed to an average radiation field of 1,000 R/h, with the most intense radiation field expected to be found at the surface of the storage bins, where it could be as high as 2,000 R/h.

The only way to know if the Elios 3 could tolerate this much dose and keep flying was to perform a test, and see how the drone performed.

Testing the Elios 3's Radiation Tolerance

Engineers involved in the calcine retrieval project performed radiation testing on the Elios 3 drone using a high-power X-ray generator.

Testing goal

The goal of the radiation tolerance tests was to make sure the Elios 3 would work as intended even when exposed to the radiation fields inside the storage vault.

The minimum test objectives for the Elios 3 required:

- Successful operation in a 1,000 R/h field

- Successful continued operation after an accumulated dose of 1,000 R

Testing location and methodology

Testing occurred at the Idaho Accelerator Center on the Idaho State University campus in Pocatello, Idaho using a high-powered 450keV X-ray tube to generate the ionizing radiation fields.

The Elios 3 was irradiated while operating to evaluate its performance while exposed to varying radiation field strengths. To obtain the most accurate indication possible of absorbed radiation, dosimetry detectors were attached directly to the Elios 3.

Chart depicting dose rate versus distance to source for 450keV X-ray generator

Testing Outcomes

After exposing the Elios 3 to various fields of radiation, CRP engineers found that the Elios 3 not only met the minimum requirements for radiation tolerance—it far exceeded them.

Here are the findings from the radiation tolerance testing:

- The Elios 3 met minimum requirements and was able to operate in a field of 1,000 R/h and continue to function after an accumulated dose of 1,000 R.

- The Elios 3 exceeded the minimum requirements of the test, operating successfully in a 10,000 R/h field and continuing to function after an accumulated dose of approximately 4,000 R.

To better understand the magnitude of 4,000 R, it is roughly equivalent to 800 times the dose a person working in an irradiated environment is legally allowed to be exposed to within one year (based on a 5Rem dose per worker, per year).

In total, the Elios 3 completed 19 individual flights of six minutes each in radiation fields of varying strength. The drone was irradiated during each flight, and then the X-ray was shut off after the drone landed, simulating the dose exposure it would receive inside the vault.

The Elios 3 flying after receiving a six-minute irradiation at 10,000 R/h

It’s important to note that the Elios 3’s ability to fly while irradiated was not the only function of the drone the IEC tested. The drone’s visual camera and LiDAR sensor also needed to work, along with all the other components you would expect to use for a typical drone operation, like the transmitter and the gimbal.

During the radiation test flights, the following components were periodically tested and/or monitored to ensure they continued to perform as intended:

- Visible camera feed

- Flight control

- LiDAR function

- Gimbal control

- Smart lighting control

- Transmitter status

- Battery voltage

Read the IEC's full report on radiation tolerance testing for the calcine removal project.

It should be noted that since this test, Flyability has launched a RAD payload in partnership with Mirion Technologies that adds to the capabilities of the Elios 3 in nuclear and radioactive environments.

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)