- Case Studies >

- 7-Minute Drone Penstock Inspections with the Elios 3

7-Minute Penstock Inspections with the Elios 3

BENEFITS IN A NUTSHELL

|

SAFETY Using the Elios 3 eliminates work in dark, confined spaces as well as fall risks from work at height. The drone enabled remote access that kept the inspectors safe while gathering critical data. |

SPEED A typical penstock inspection can take several hours or even days - but with the Elios 3, all of the necessary data was collected in just 7 minutes. |

|

ACCESS In the past, a custom trolley was required to get data about the condition of the penstock. This time, the Elios 3 gathered all of the data in 7 minutes. In that short period of time, they gathered clear visual data as well as the LiDAR point cloud, ready for use in maintenance and condition assessments. |

DATA QUALITY The 4K video and accurate point clouds created by the Elios 3 amaze both Sichuan Institute of Geological Engineering Investigation Group and their clients, giving them clear insights with minimal risks to staff without compromising on data quality. |

At its core, a hydropower plant uses water to move turbines and generate electricity. A penstock is the structure responsible for transporting the water from a reservoir to the turbine deck. These huge piping systems are essential to the smooth operation of a dam and as a result, require regular inspections to ensure the penstock is in a safe and working condition. Penstock condition assessments can be very difficult, involving work in confined spaces at height and in pitch darkness. Drone penstock inspections are an alternative method that is rapidly gaining popularity as they provide safer, faster, and more comprehensive access to these critical structures.

Innovating Penstock Inspections with Drones

The Sichuan Institute of Geological Engineering Investigation Group Co. Ltd (SIGEIG) provides construction and engineering surveys, geological disaster risk assessments, and complex inspection services to mining, infrastructure, and energy companies in Southwest China. Their Surveying and Geoinformation department uses cutting-edge technology including the Elios 3 drone to complete their inspections.

The Geoinformation Department first heard of the Elios 3 in October 2023 and in June of 2024, they integrated this technology with their workflows. They found that the Elios 3 drone effectively addressed key challenges that arose in surveying high-risk zones where personnel could not gather information safely. This includes penstock inspections, where they need to assess the structure and identify any defects in the water conveyance system.

Team members from SIGEIG pose with their Elios 3 drone

Why is the Elios 3 Suitable for Penstock Inspections?

SIGEIG invested in the Elios 3 soon after discovering the capabilities of the drone as they saw it could help them in three key areas:

- Reducing risks to personnel through remote inspections

- Improve operational efficiency through easy, remote access

- Deliver comprehensive results with real-time digitalization and visualization.

Since adopting the Elios 3, SIGEIG has been able to rapidly improve its inspection efficiency and safety across various projects. This includes using the Elios 3 to survey a tunnel and covering 1,200 meters in a single day - whereas traditional methods would only cover 300 meters in the same period of time. They’ve seen cost reductions as high as 90% as a result of using the Elios 3 drone, alongside efficiency improvements of 400%.

The Elios 3 can easily gather data along the length of the penstock without the team having to use a custom trolley in a slower, more compliated process

SIGEIG has also found that the inspection reports with the Elios 3 are highly valued by their own surveyors and external clients. The combination of comprehensive data coverage with the elimination of risks to personnel has made the Elios 3 a winning combination, and the perfect drone for penstock inspections. The drone’s 4K camera, precise LiDAR scanner, and powerful lighting rig make it well-suited for penstock assessments without adding complexity to the overall inspection process.

Planning a Drone Penstock Inspection

In this mission, SIGEIG needed to inspect a penstock at a hydropower plant in Southwest China. They needed to check the concrete surface of the pipe’s interior, looking for signs of cracks, spalling, exposed reinforcement, honeycombing, erosion, and seepage. In order to identify these defects, a detailed visual inspection is required.

In the past, this dam’s inspection team would create a custom trolley on wheels that could be pushed through the space. A FARO S350 scanner would be mounted onto it and a steel rope traction system would lower the trolley down the tunnel. This progressive, station-based inspection method is slow, prone to gaps in data, and has inherent risks due to the nature of the penstock’s shape. These dangers include falls from height and equipment water ingress.

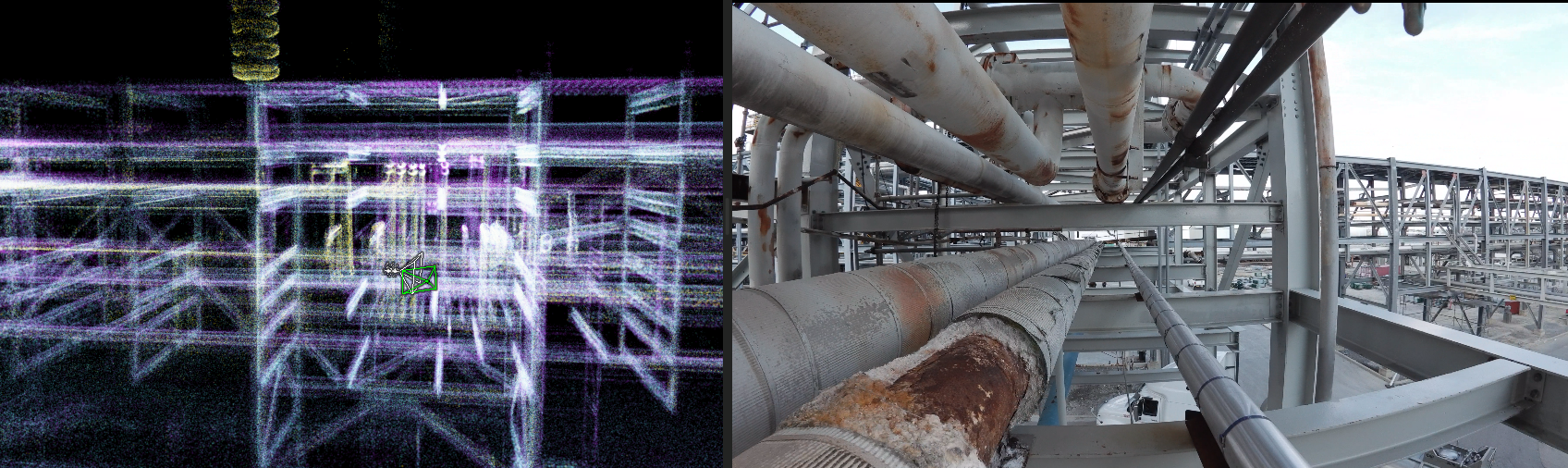

The Elios 3's results viewed in Inspector show the visual inspection results alongside the LiDAR point cloud

SIGEIG knew that the Elios 3 offered a safer, easier way of assessing the penstock’s condition. They deployed their Elios 3 drone and used its 16,000-lumen lighting system to guide the pilot through the space. The drone was flown down the centerline of the penstock where it could have good, comprehensive coverage of the space. The plan was to use the 4K camera and LiDAR sensor to gather the necessary data. The 3D model from the laser scans would allow the maintenance team to localize defects spotted on the camera within the penstock’s overall structure and efficiently plan repair work.

The entire flight was completed in just 7 minutes. This short duration was more than enough to gather all of the information required for this inspection, demonstrating the high efficiency and comprehensive data coverage achievable with drone penstock inspections. This method kept the SIGEIG team safe while they assessed the penstock.

Ready for Regular Drone Penstock Inspections

SIGEIG revolutionized the inspection process for penstocks at this site thanks to their Elios 3 drone. This was just one of a series of projects they have undertaken with their drone but it clearly demonstrates the value of drone inspections for hydropower applications. SIGEIG also highlighted the value the drone provides in beyond-the-visual line of sight (BVLOS) inspections, where the rugged design of the UAV gives them the confidence to take on challenging inspections.

Compared to traditional management methods, this drone penstock inspection performed far better without compromising inspector safety or prolonging downtime. The Elios 3’s unique capabilities and accurate data collection made it a highly successful mission, adding to SIGEIG’s existing portfolio of Elios 3 projects.

Discover more about how the Elios 3 is used in power generation inspections.

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)