- Case Studies >

- Mapping 13 kilometers of underground technical galleries in...

Mapping 13 Kilometers Of Underground Technical Galleries In Brussels

Benefits In A Nutshell

|

Safety |

Speed |

|

Data quality |

Access |

Brussels is an incredibly influential city. Home to the European Commission, it hosts a huge international community alongside a bustling business and cultural side. With the nickname “Capital of Europe”, this city is a natural place to develop smart city practices.

Smart cities use technology to collect data and optimize how the city operates. This includes anything from smart traffic lights to green architecture. A smart city works best through an amalgamation of smart technology, system optimization, and comprehensive asset management.

The Maintenance and Inspection Department at Brussels Mobility launched a campaign to survey technical galleries and networks underneath the city as part of a project to optimize the management of these spaces. Some of these galleries had been built decades ago and no up-to-date records existed. Brussels Mobility wanted to assemble a specialist team to survey and map the underground galleries so they could plan any maintenance as well as optimize how the space is used.

Creating A Specialized Underground Survey Team

The presence of the underground galleries was known, but their location, size, and network was not. Brussels Mobility’s aim was to build an inventory and accurate record of the galleries, their contents, and what maintenance was necessary. With no as-designed records to compare against, they needed to create a detailed as-built resource to understand the situation.

Brussels Mobility partnered with several companies to begin this survey. They wanted to find specialists in data collection and processing for the project, as they needed to access areas that had no records - the level of safety or even what was left behind in the galleries was unknown.

SECO was the first partner on the project. SECO work in engineering and construction, and were brought on to investigate defects in the concrete structures and assist in data collection. The confined spaces underground were expected to be complex and may have had some hazards. SECO planned to use a drone for the data collection and they included a specialized drone inspection partnership to join them.

The project to map the underground galleries required expertise from a variety of companies to ensure quality data collection and processing while keeping the teams safe

Sweco has multiple projects for Brussels Mobilité and was assigned to create an inventory of the underground structures that are used for utilities. Sweco is a leading engineering and architecture consultancy. Their expertise for this project was needed to help process and analyze the data collected. They use LiDAR and visual imagery to create comprehensive 2D maps and 3D cross-sections of the underground locations.

Medexon and Flywel are partner companies that provide drone inspection services across a variety of industries in Belgium. Part of what makes them unique is the Elios 3 drone that is part of their fleet. They were asked to join this project so that they could help inspect hazardous, confined spaces as well as scout areas prior to human entry.

With this highly qualified team assembled by Brussels Mobility, it was time to begin the inspection and surveying project.

Image right: The Elios 3 and its Surveying Payload were able to easily enter and scan spaces with safer access and faster turnaround than visual inspections on foot.

Underground Surveys With The Elios 3

The data collection team set out with 3 key aims for this project.

- Gather data for unknown areas. Many of the galleries and spaces had little to no records of their condition. It was important for Brussels Mobility to have up-to-date information on their layout to understand the size and scale of the network.

- Identify assets and equipment. The data collected by SECO and Medexon-Flywel needed to provide information about all of these elements.

- Look for concrete cracking. As much of this network is underground and has had little maintenance thus far, Brussels Mobility wanted to determine the structural condition of concrete and the walls in the galleries.

The varied and challenging conditions of these inspections meant that there were hazards the inspection team had to be aware of too.

Entering the galleries included going to access points across the city to gather data. All data collection was georeferenced to create a final map in the end.

Complex Underground Mapping With A Drone

The data collection team had no idea what to expect in the galleries. They faced potential hazards such as electrical cables potentially being in water due to drainage faults or large equipment blocking the way. For this reason, the team desperately needed a tool to help scout spaces as well as collect data.

The Elios 3 was used for just this purpose. Despite operating in cold temperatures, the team were able to use it for over 200 flights to gather LiDAR and visual data across 13 kilometers of underground spaces.

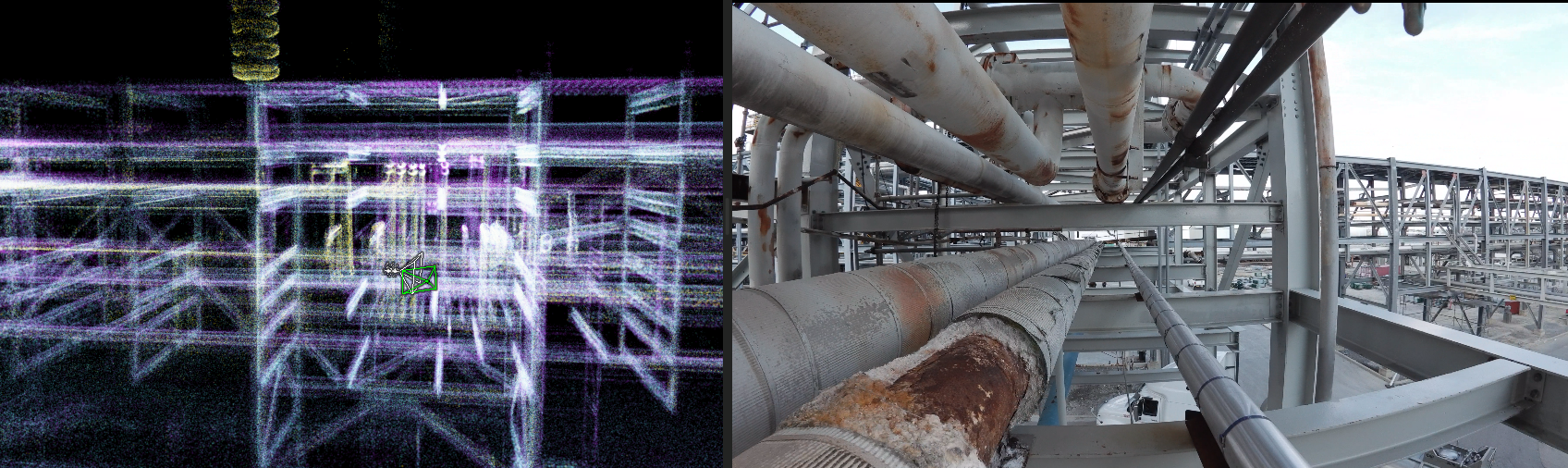

The drone flights explored confined spaces as well as more spacious underground locations

During this period, the Elios 3 Surveying Payload was also used to survey particularly difficult underground sites, including storm drains. This payload has optimized workflows for handling similar locations that can present a challenge to LiDAR scanners. In some cases, the team held the Elios 3 in their hands to collect LiDAR data where flying was not possible.

Interested in learning more about the Elios 3, the Surveying Payload, and drift reduction? Read our accuracy report.

Surveying 13 Kilometers With The Elios 3

Despite the magnitude of this project, the team was able to successfully collect data from all of the desired locations. This spanned 13 kilometers including storm drains, galleries, and technical rooms. 241 flights were conducted across over 9 days of intensive flying. During these flights, 1,776 points of interest were recorded.

The data processing and mapping for this project has been a mammoth task for all involved. In some cases, the team saw the impact of drift in the LiDAR datasets, and worked with the Flyability team to optimize their results. Sweco has since been able to create a detailed LiDAR map with an overlaid surface map to see the location of mapped assets underground compared to the overground environment. This is incredibly helpful for planning any maintenance or further inspection work as it means Brussels Mobility and their partners can easily identify access points and plan their operations.

The gallery maps are carefully referenced and ready to assist maintenance work

The gallery maps are carefully referenced and ready to assist maintenance work

This project has been going on for a year to date, with open collaboration between all the teams involved. It has been a massive success in helping gather comprehensive and actionable data for Brussels Mobility, who can plan the future of these underground spaces.

In the future, Brussels Mobility hope to share this data with utility companies to help with maintenance and repair of assets or equipment underground, as well as use the maps to plan how these galleries can be repurposed for public use.

Underground surveys with drones, whether they are in mines, sewers, or technical galleries, are made faster and safer thanks to the speicialized UAVs present. The Elios 3’s ability to both collect data and provide situational awareness helped keep the team safe despite the complex task they were completing, even in GPS-denied environments. Medexon-Flywel are confident in the drone’s capabilities to complete future projects of a similar nature - especially with the new Surveying Payload.

Discover more about the Elios 3 and its specialized LiDAR payload

All images in this article are credited to CLP Power.

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)