- Case Studies >

- Tank Ultrasonic Thickness Measurement With The Elios 3

Tank Ultrasonic Thickness Measurement With The Elios 3

The Elios 3 made it possible to get tank ultrasonic thickness measurements when pilots flew the drone inside the stainless steel tank, even when it was full.

Benefits In A Nutshell

|

Access Thanks to the Elios 3's size and agility, it could be flown in the double wall of the tank which meant the inner space did not have to be emptied, minimizing disruption. |

Safety No human entry was required thanks to using the Elios 3! This eliminated the risks of confined space entry as well as potential work at height via rope access. |

|

Speed The Elios 3 completed 84 measurements with the ultrasonic thickness payload, far outpacing traditional inspection methods for inspecting stainles steel tanks of a similar size.

|

Efficiency Using the Elios 3 meant they didn't need to empty the tank, eliminating downtime and demonstrating how drones can be built into inspection workflows efficiently, rather than adding time to workflows.

|

Industrial tanks are in constant use and careful tank storage management can be the critical factor in work and supply lines operating smoothly - or the root cause of delays. On average, a large storage tank could be expected to be in use for a minimum of 20 years, but with careful maintenance, its lifespan can far exceed this. The foundation of effective maintenance comes from detailed inspections. This is where the challenge may lie.

For a tank to be inspected, both visually and for thickness measurements, the tank usually has to be empty. A person or crew must then enter the tank, either through small manholes or high access points. The tank needs to be carefully cleaned before people can enter as there can be fumes that are toxic for humans. All of this makes tank inspections slow, costly, and inconvenient. But new technology now offers a turning point - the Elios 3 and its UT payload make it possible to complete these inspections with significantly fewer safety, time, and resource constraints.

Demonstrating Tank Ultrasonic Thickness Measurements with the Elios 3

Ingenieursbureau Klink BV is an inspection company that specializes in major industrial assets, including tanks. They have a deep understanding of the challenges associated with emptying, cleaning, and inspecting tanks across industries. As part of optimizing their work, they introduced the Elios 2 to their visual inspection processes in 2018, before upgrading to the Elios 3 in 2022. They have been using the Elios drones to check tank integrity, relying on the visual and LiDAR payloads.

The Elios 3 with its ultrasonic thickness payload ready for a tank inspection

The Elios 3 with its ultrasonic thickness payload ready for a tank inspection

Now, with the addition of the UT payload to the Elios 3 drone, they have the opportunity to eliminate any unnecessary human entry to collect ultrasonic thickness measurements. This takes the Elios 3 from being a visual scouting tool to being firmly integrated with the inspection process itself. Working in partnership with local partner Vortex, a team from Klink traveled to an energy plant to complete a tank inspection using the UT probe to test how effective it would be.

Planning an Ultrasonic Thickness Inspection for a Stainless Steel Tank

The double-walled stainless steel tank (2900m3) chosen for this inspection was largely filled with diesel fuel. Due to the very small space in the double wall, the (internal) tank would have to be empty and cleaned to carry out the measurements. Scaffolding would also have to be built for the measurements on the higher wall rings. The new plan was to perform the measurements on the inner tank from the double wall with the Elios 3 and its UT payload. By using the drone, the inner tank would not have to be opened and the measurements were carried out in accordance with current regulations without needing scaffolding or additional access methods.

When planning the flight, the team from Ingenieursbureau Klink BV and Vortex wanted to demonstrate how quickly and safely they could gather ultrasonic thickness measurements in each flight. They wanted to gather clear data that could be replicated in a follow-up flight in several months. This would allow the asset owner to track changes over time and track the maintenance needs of the tank accurately, with results stored in a digital 3D model of the plant.

Making Ultrasonic Thickness Measurements Inside a Stainless Steel Tank Using the Elios 3

The Elios 3 pilot flew into the double wall of the tank with the UT payload mounted. They started taking measurements across 4 scanlines. On each scanline, 3 measurements were taken from 7 plates. By the end, the pilot had captured 84 measurements.

The Elios 3's UT payload makes contact with the surface to take an ultrasonic thickness measurement.

The Elios 3's UT payload makes contact with the surface to take an ultrasonic thickness measurement.

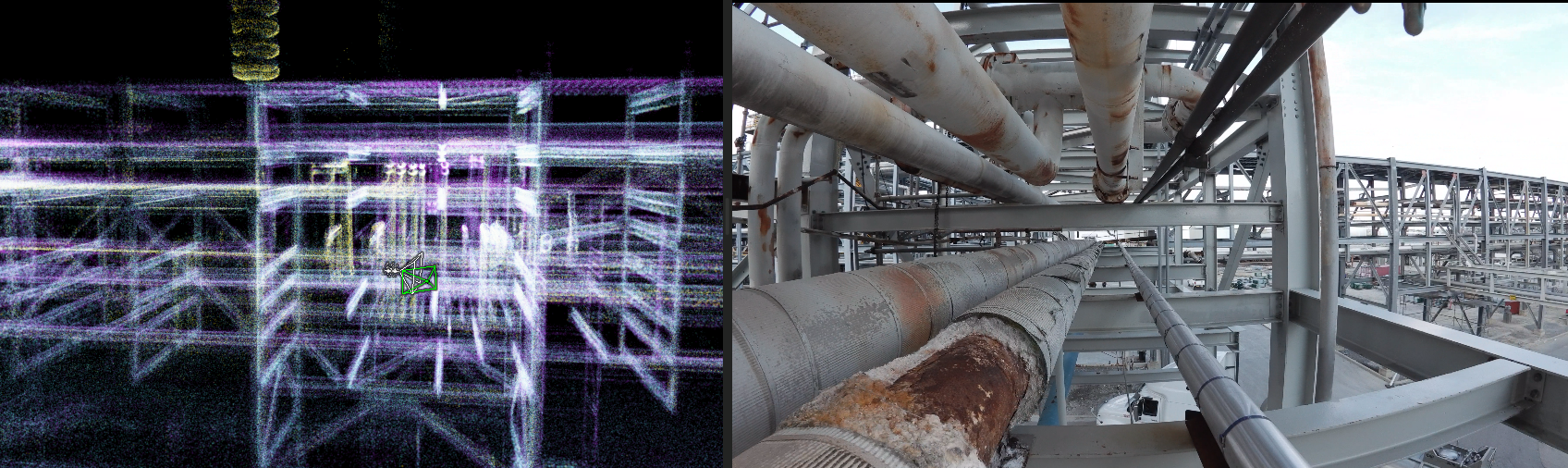

In analysis, the UT measurement points were visualized on the 3D point cloud from the Elios 3’s LiDAR payload. This means it will be easy to measure the exact same points when the team returns to the tank for a future inspection. This localization is highly valuable as it can be hard to measure the same point during repeat inspections, whereas with the Elios 3 (and its Asset Management software) it is possible to see previous measurements in the asset when completing a flight in the same location.

At the end of the mission, the results were shared with the client, who was very impressed with the speed of the inspection as well as how it compared to the labor and cost-intensive alternatives with tank emptying, cleaning, and scaffolding for human entry.

Setting a Precedent for Tank Ultrasonic Thickness Inspections with the Elios 3

Although this project was the first of its kind for Ingenieursbureau Klink BV, they expect to complete multiple similar assignments when they receive their UT payload from Flyability. The massive improvement to safety coupled with the speed of inspection is on a completely different level to what was done previously. Human entry was entirely eliminated from the inspection process which was never possible before.

Each ultrasonic thickness measurement point is clearly visible in the point cloud, with the option to add annotations to the point of interest for ease of analysis

“We are very pleased with the quality and speed of the measurements. The very limited space in the double wall has also not proven to be an issue” - Ingenieursbureau Klink BV

This industrial site is owned by a major company, and as Ingenieursbureau Klink BV explains, the majority of big companies are interested in safety improvements. They are not focused on the details of how greater safety is achieved and thus will try new technology that seems promising. The value of this project with the Elios 3 is that it clearly brought safety improvements alongside improving the overall efficiency of the inspection.

Moving forward, Klink is looking forward to unlocking ultrasonic thickness inspections with their Elios 3 drone and its UT payload. Their existing work with drones already sets them apart from competitors, and this development is taking their unique service offering to a new level. This initial stainless steel tank inspection using the Elios 3 and its UT payload was a milestone for them - but soon they hope to complete similar assignments as part of routine work.

.jpg)

.png)