- Case Studies >

- Inspecting Elevator Shafts with the Elios 3 in New york

Inspecting Elevator Shafts with the Elios 3 in New York

Gedeon GRC Consulting used the Elios 3 drone to fly inside the elevator shafts and mechanical, electrical, and plumbing (MEP) vents for a construction project in Brooklyn, NY, providing safe access to critical environments during the preconstruction phase.

Benefits In A Nutshell

|

Access Without the Elios 3, gathering data in these environments would have been extremely difficult, requiring dangerous and complex rope access methods. No other feasible solution existed for scanning these areas. |

Safety Using the Elios 3 eliminated the need for confined space entry or rope work to collect data, keeping the team safe and improving overall safety standards. |

|

Data Quality The results from the Elios 3 provided critical insights into the condition, shape, and dimensions of the elevator and MEP shafts. The final outputs were exported as E57 files and shared with the client, who was able to move to the next phase of the project with this data. |

Speed All data collection was completed within 1 day in just 8 separate flights. This type of work would likely have taken several days alongside additional safety measures without the Elios 3. |

Few cities boast an architecture and infrastructure as famous as New York. Popularized through TV, film, and literature alongside the city’s position as a global financial powerhouse, the buildings and bridges that make up the city are easily recognized.

Managing that iconic infrastructure is a unique undertaking. The city’s bustling schedule means that structures are in frequent use, meaning new construction and maintenance work can easily disrupt the lives and work of surrounding businesses and people. However, some industry experts are finding ways to complete complex maintenance and refurbishment projects despite the challenges of working in the heart of the Big Apple - and that includes Gedeon GRC Consulting.

Gedeon GRC Consulting uses the Elios 3 and other remote inspection tools to safely gather quality data

Backed by 25 years of experience, Gedeon GRC Consulting is well known in the city for its innovative solutions to complex construction projects, ranging from inspecting tunnels to surveying building projects. The city’s Economic Development Corporation (EDC) is currently leading a project to refurbish the Brooklyn Army Terminal. This warehouse complex occupies over 95 acres, and with several structures ready for renovation, there is a delicate balance between surveying, designing, and enacting construction plans on the site while staying on schedule and budget. Pioneering construction solutions, Gedeon GRC Consulting’s robotics team was asked if they could find a safe, efficient method to access elevator and MEP shafts. Here’s how they did it with the Elios 3.

Inspecting Elevator Shafts with Drones

The Brooklyn Army Terminal complex covers millions of square feet, with the entire site facing various levels of rehabilitation. During the preconstruction phase, there is limited access to some areas and a tight scanning and surveying schedule, putting pressure on the teams collecting data.

One building in the terminal is 8 stories high with a 30 - 40 meter (98 - 130 feet) rise in the elevator shafts. Elevator and MEP shafts are sealed off from easy access for safety reasons, which is ideal when a building is in use, but this makes any planning and surveying difficult during refurbishment.

Gedeon GRC Consulting’s team was already familiar with the site and client managing the site, so when they were asked if they could find a way to safely access these elevator and MEP shafts, they turned to their in-house robotics department. Traditional laser scanners would be used to scan the floor plates and location of pillars throughout the site, but the shafts called for a new solution. The robotics department, led by director Miles Kilcourse, was confident that they could get access with minimal disruption to construction schedules and no rope work for the team, adhering to the overall goal of safe, efficient access. Their chosen solution was the Elios 3 drone, which they have mastered with support from MFE Inspection Solutions.

Why Use the Elios 3 Drone to Inspect Elevator Shafts?

The Elios 3 is the ideal solution for this type of work due to its specialized design for confined spaces. The drone can be flown beyond the line of visual sight and capture both 4K images and centimeter-accurate LiDAR scans - both of which are of value to this project.

The robotics department from Gedeon GRC Consulting highlighted several features of the Elios 3 that made it well-suited for this task:

- Access – the main pain point of elevator shafts in construction is the limited access and work at height, both of which are not issues for the Elios 3. Being able to use the drone and trust it to fly and withstand light collisions gave the team confidence in their solution.

- Data Quality – using the Elios 3’s surveying payload, the team from Gedeon GRC Consulting can capture and process highly accurate laser scans, delivering them in an industry-standard format that can be integrated with other scans. This provides accurate site information that can be seamlessly integrated with other data collection methods, culminating in a final, comprehensive Scan to BIM output.

- Speed - the Elios 3 is easy to fly and direct through complex environments, making the process of collecting the data swift and painless. This resulted in Gedeon Consulting’s team finishing data collection ahead of schedule, saving both time and money by preventing delays to the construction phase.

Fly the Elios 3 Drone Inside Elevator Shafts

The construction team on-site expected that to gain access to the elevator shafts, they would have to break down several walls and take extensive precautionary measures to ensure the safety of the team. Instead, the Gedeon GRC Robotics department only needed assistance cutting a 2x2-foot hole in the wall - far smaller than the expected 8x10-foot space usually required for rope access.

The Elios 3 pilot from Gedeon GRC Robotics department then safely prepared the drone, took flight, and entered the elevator shaft, flying up and down the space to gather all of the necessary data with both the 4K camera and the surveying payload’s LiDAR scanner. In some of the larger elevator shafts, a second flight was required.

Moving quickly between different shafts, the Gedeon GRC Robotics department only needed to do 8 flights with their Elios 3 to gather all of the necessary data. In each instance, the slowest part of the process was cutting through the wall - the Elios 3 flights themselves were completed in under 25 minutes per location. In total, the team was on site for just 1 day.

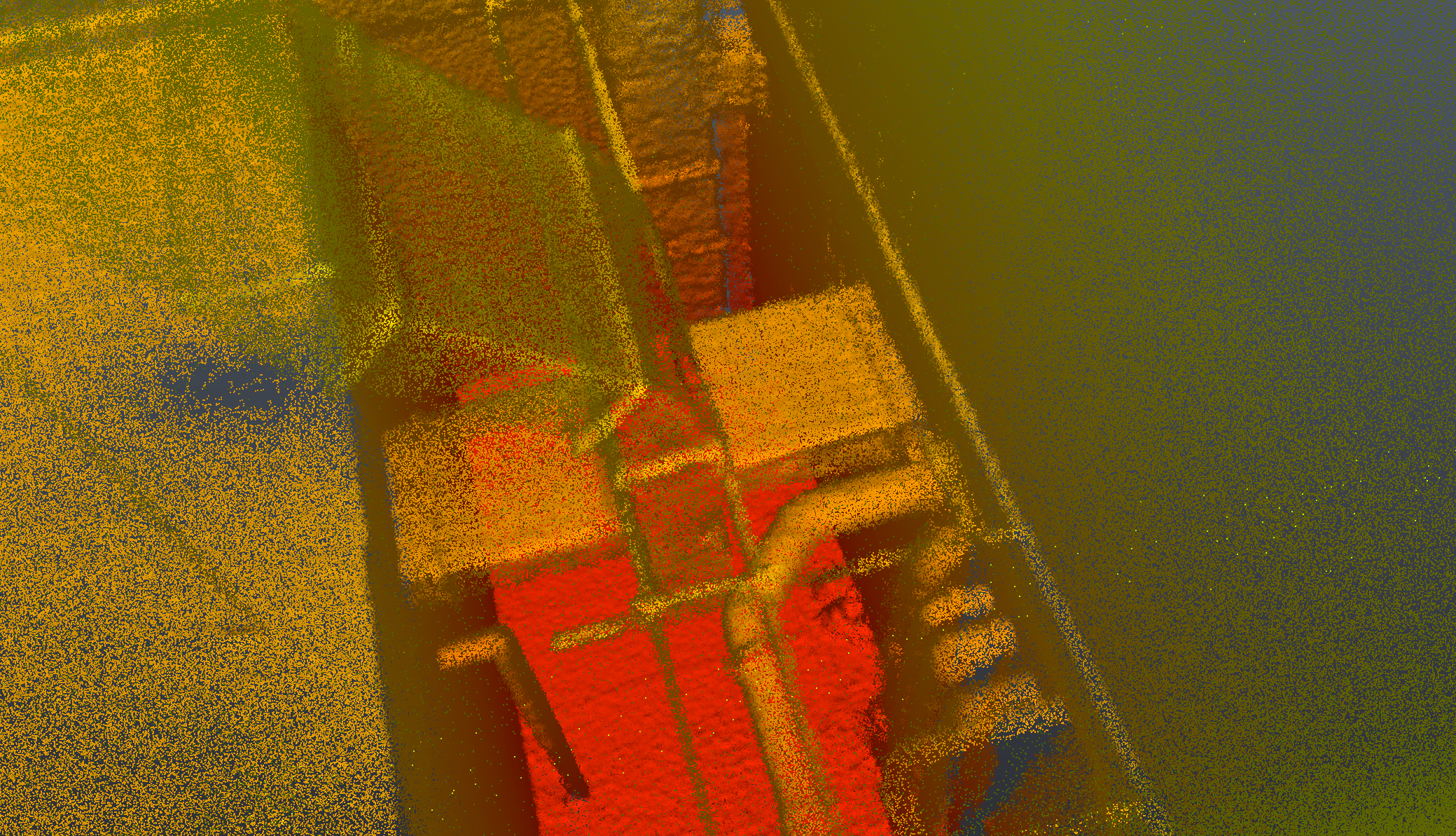

The data from the Elios 3 was then imported to FARO Connect, where the Gedeon GRC Robotics department analyzed the results and aligned the point clouds from different flights. Once happy with the result, the data was exported in E57 files that Gedeon GRC integrated with the larger building scan. This data was then turned over to the client, with the expected use to be in Scan to BIM projects to assess the building’s current structure and plan upcoming refurbishments.

Impact of Drone Inspections in Lift Shafts

Gedeon GRC Consulting’s team brought an innovative solution to a project that is contingent on following a tight project deadline and ensuring the highest level of safety on a major construction project. The use of the Elios 3 eliminated confined space entry and provided data with enough detail for the EDC to assess the shaft conditions and plan the next phases of the refurbishment project.

A point cloud screenshot from Gedeon GRC Consulting's data as they analyzed their results

“Eliminating confined space entry was a major factor for this project, and our speed of data collection alongside the quality of our results impressed the client. This project was an opportunity for us to expand the quality of our work and showcase our standards for excellence,” explains Miles.

Moving forward, Gedeon GRC Consulting is keen to continue deploying its variety of solutions, ranging from industry expertise to cutting-edge robotics, to overcome obstacles while working on projects in the heart of an iconic city. Thanks to the Elios 3, they were able to quickly and safely gather data and deliver highly accurate results. This project was a successful continuation of Gedeon GRC Consulting’s commitment to innovation and revolutionizing complex infrastructure management.

Interested in learning more? Discover the Elios 3 now!

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)