- Case Studies >

- Mining More Efficiently at Glencore Kidd Operations With...

Mining More Efficiently At Glencore Kidd Operations With Elios 3

Discover how Elios 3 inspected and leveraged data from one of the most inaccessible places, 10.000ft under sea level.

Benefits In A Nutshell

|

Savings Elios 3 can inspect and map large areas with minimal personnel and without the need for taking production loaders out of operation in other areas to carry LiDAR sensors. Costly drilling to identify issues in vertical spaces is minimized by scanning with the Elios 3. |

Speed Elios 3 can scan more distance in less time than inspectors on foot. Easily executed data scans in vertical spaces minimize the need for costly and time-consuming drilling to identify hang-ups or other issues. Live streaming of data during scans minimizes the need for multiple deployments. |

|

Safety Elios 3 is used daily to survey areas that are dangerous or inaccessible to the human workforce, allowing operators to gather data from a safe distance without the need for additional equipment. |

Operations "To get to some of the places [where we send the drone], you'd be talking about pulling a $2 million dollar loader off of its job, strapping a scanner onto it and sending it somewhere remotely. All that becomes a 15-minute job [with Elios]" - Iain McKillip |

Mining at the world's deepest base metal mine

Located in Timmins, Ontario, Glencore Kidd Operations includes the Kidd Concentrator and the Kidd Mine, the world’s deepest base-metal mine. Producing an average of 40,000 tons of copper and 70,000 tons of zinc annually, the mine reaches 10,000 feet below sea level and has the longest surface-to-bottom ramp in the world.

Glencore Kidd Operations are recognized industry innovators, prioritizing the safety of their 800-person workforce, and earning accolades for energy conservation efforts. In introducing the Elios 3, aerial LiDAR scans, and live data streaming, Glencore Kidd Operations is leveraging the best technology available to protect their workforce - and moving towards revolutionizing workflows to optimize operations.

Thanks to the collaboration between Unmanned Aerial Services Inc, Glencore Kidd Operations, and Flyability the Elios 3 was able to fly into the deepest parts of the mine, reaching depths of 10'000ft and retrieve valuable data for Glencore Kidd Operations.

Surveying challenges in underground mines

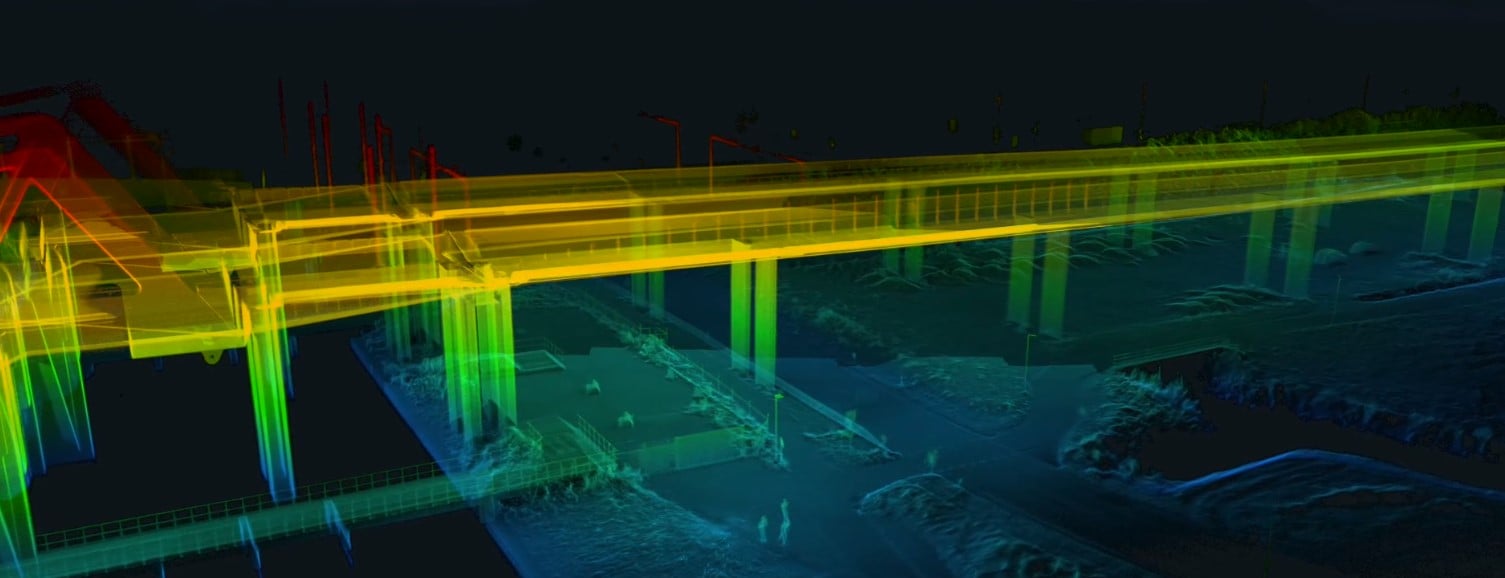

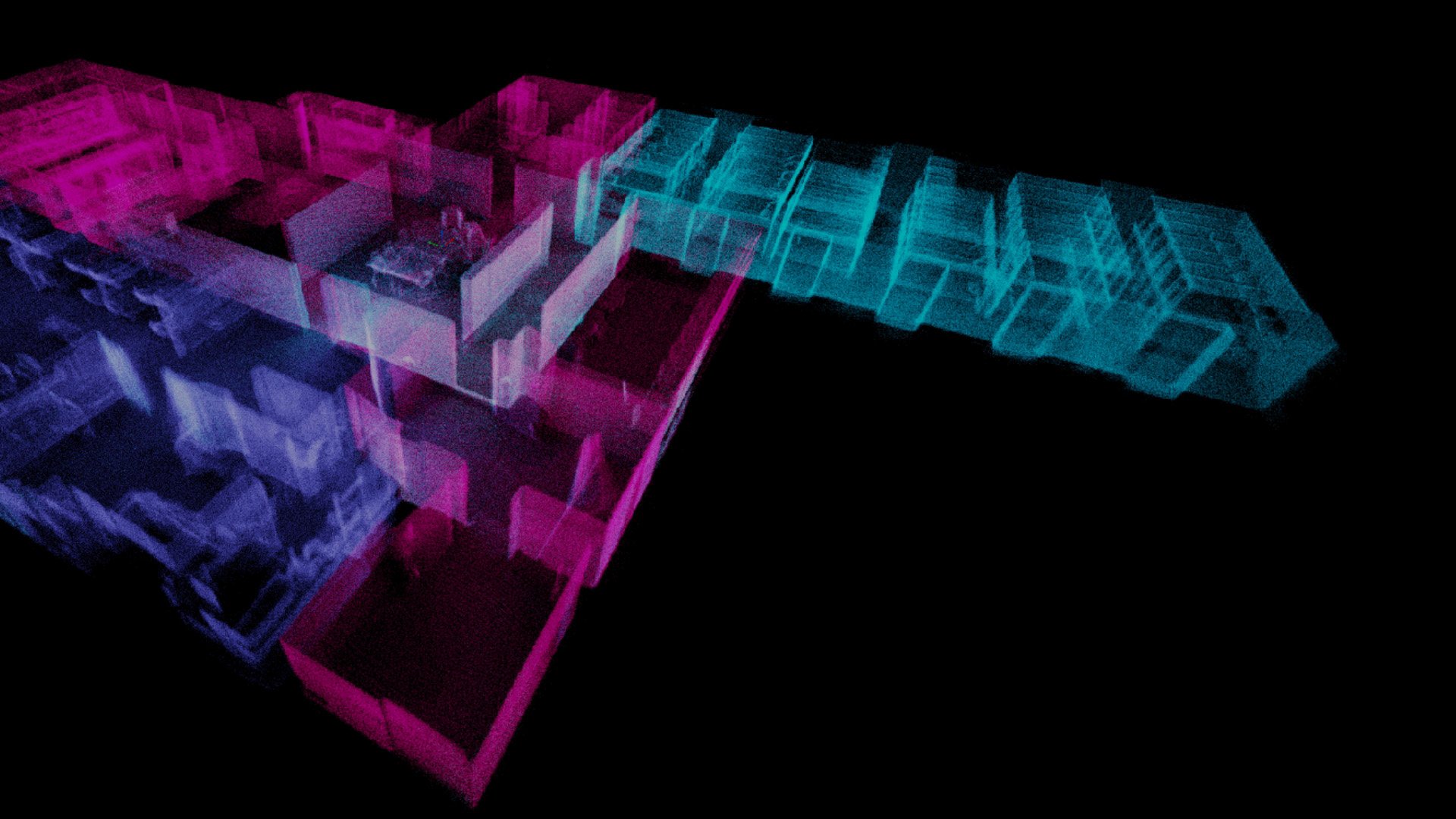

Throughout mining operations, data is critical for safety and efficiency. Glencore Kidd Operations must perform frequent surveys throughout the mine in both horizontal spaces and vertical spaces. These surveys allow mining engineers to identify and resolve ore pass hang-ups, evaluate the safety and condition of stopes, calculate blast effectiveness, survey cross-cuts, and more – keeping operations throughout the mine running safely.

Using walk-throughs, ground-based tools or other aerial systems, these surveys are difficult and time-consuming. “Being the deepest base-metal mine in the world, the conditions here are definitely a lot more challenging and unforgiving than other operations,” says James Comeau, Long Range Planning Lead.

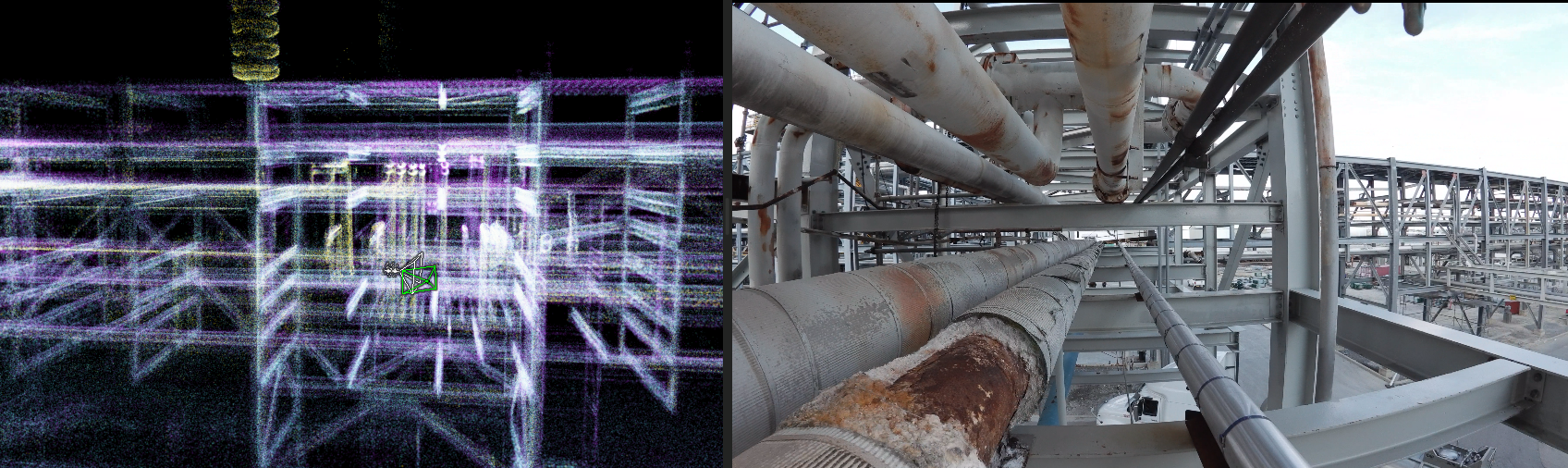

Underground areas in the mine are without GPS and subject to dust and limited or no light. In accessible areas, engineers cover large areas on foot using ground survey equipment or cameras, which produce limited data. In areas not safe for human operators, engineers must take expensive production loaders from other work and attach a scanner. These ground-based scans often result in incomplete data.

For vertical spaces, workers are frequently forced to make a guess at the location of a problem area, using production drills to access the space and inserting sensors to identify an issue. This trial-and-error work often takes days to complete and requires expensive equipment and significant human resources. These surveys also require communication and interpretation of data by the staff on the ground for use by other stakeholders. Data perceived by a single resource may not be sufficient for many of the decisions that must be made on the surface by a team of engineers.

Introducing surveying drones underground

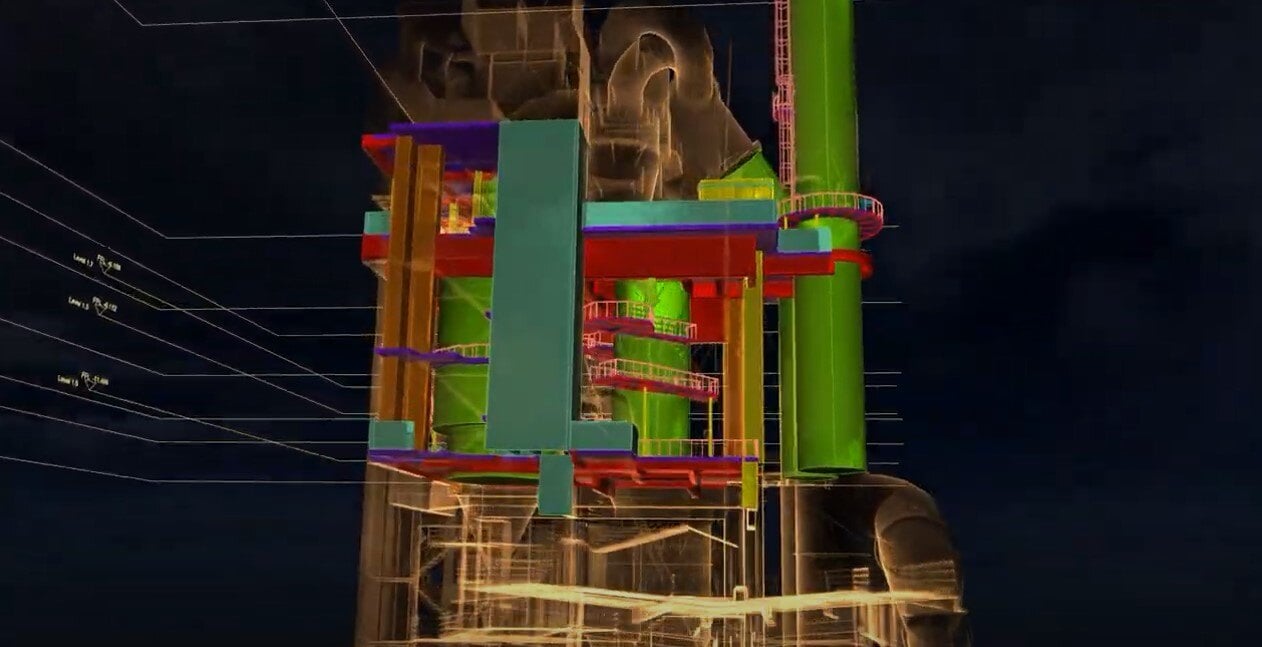

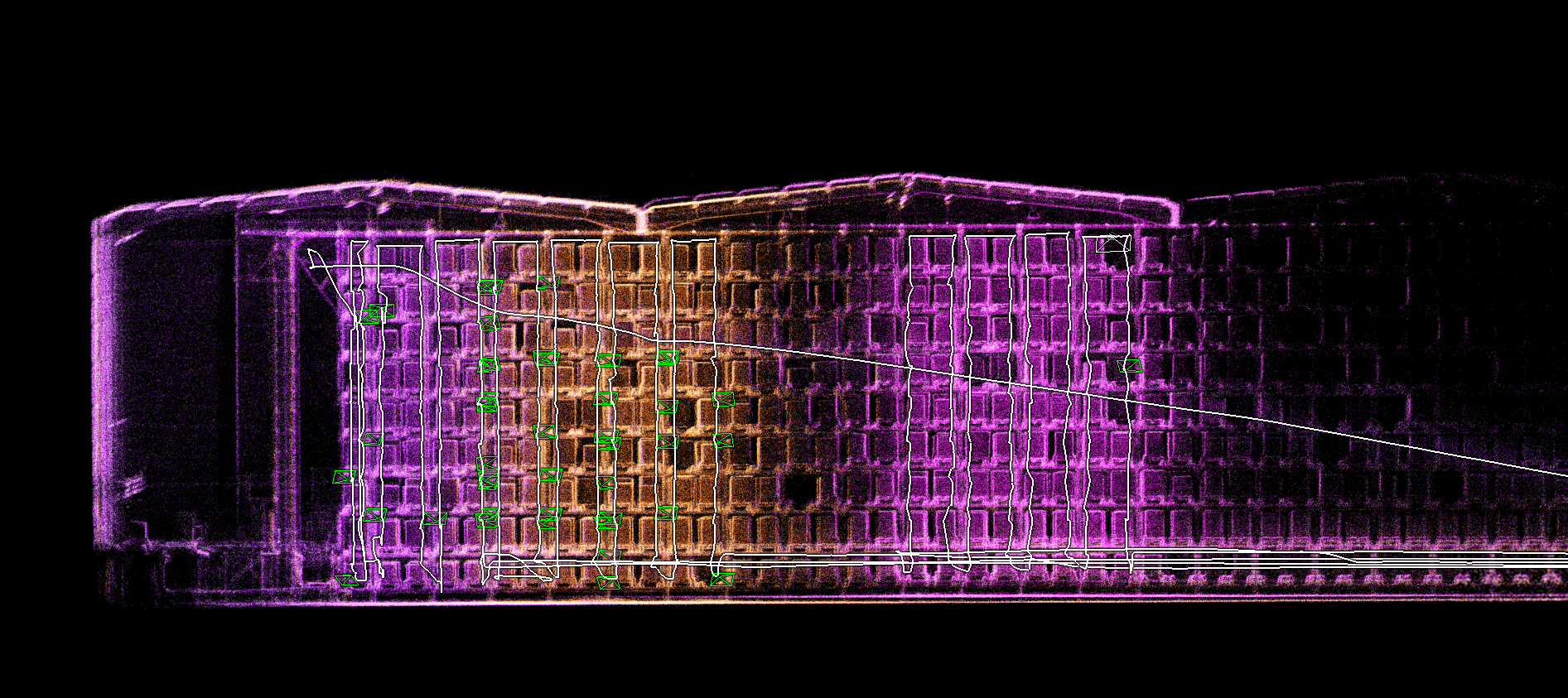

Glencore Kidd Operations has adopted the use of the Elios 3 to perform surveys and LiDAR scans throughout underground areas of the mine. The Elios 3 is designed for use in GPS-deprived and dark environments and is uniquely engineered for operation in small and inaccessible places. The Elios can scan dangerous spaces quickly and safely, allowing the human operator to work from a secure distance. Data capture is improved, as operators can broadcast the live stream to collaborate with other staff as they perform a scan. For jobs like surveying cross-cuts, engineers can scan more areas, in less time.

“You can cover so much more ground when you’re flying it with a drone than you can on foot,” says Ground Control Engineer Megan Gidden.

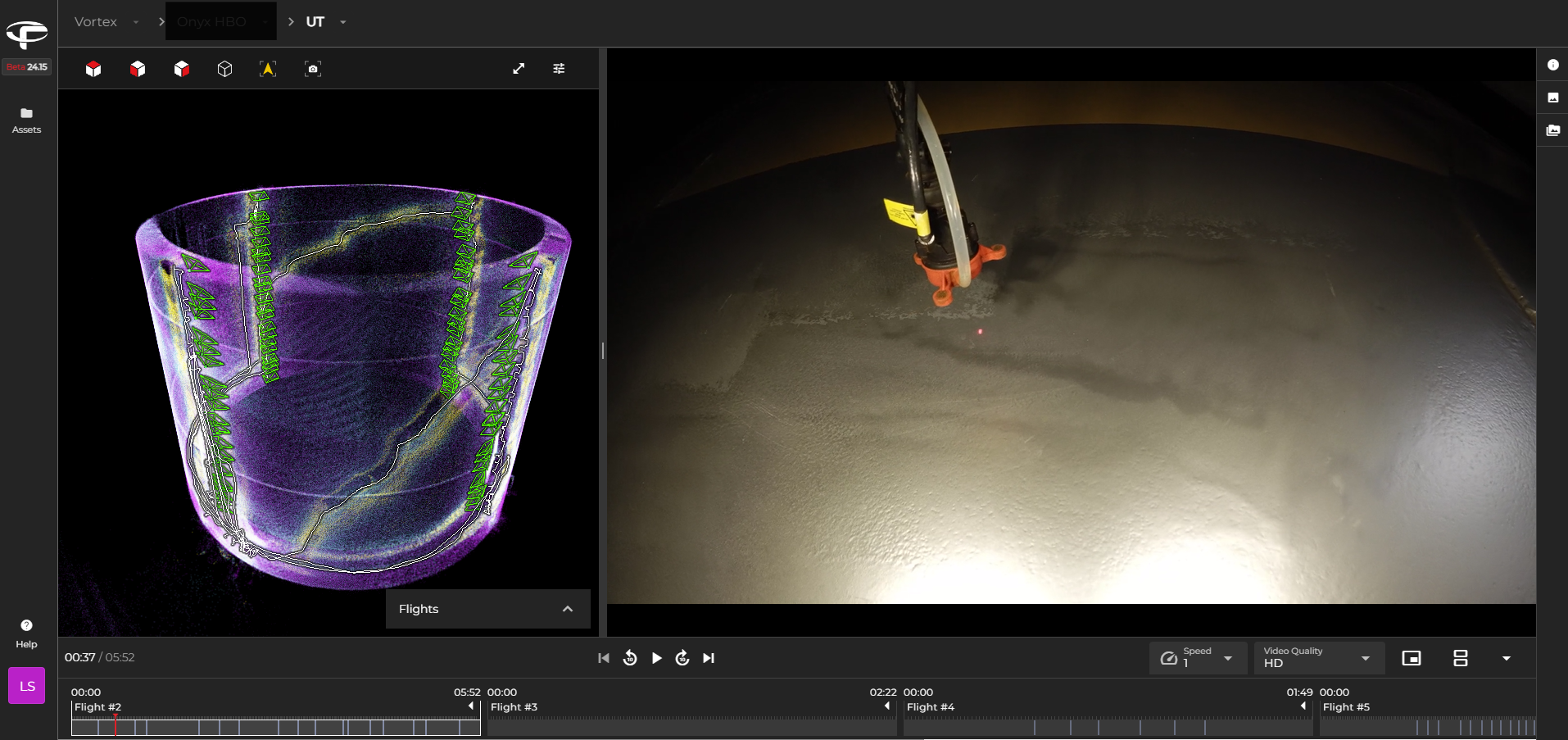

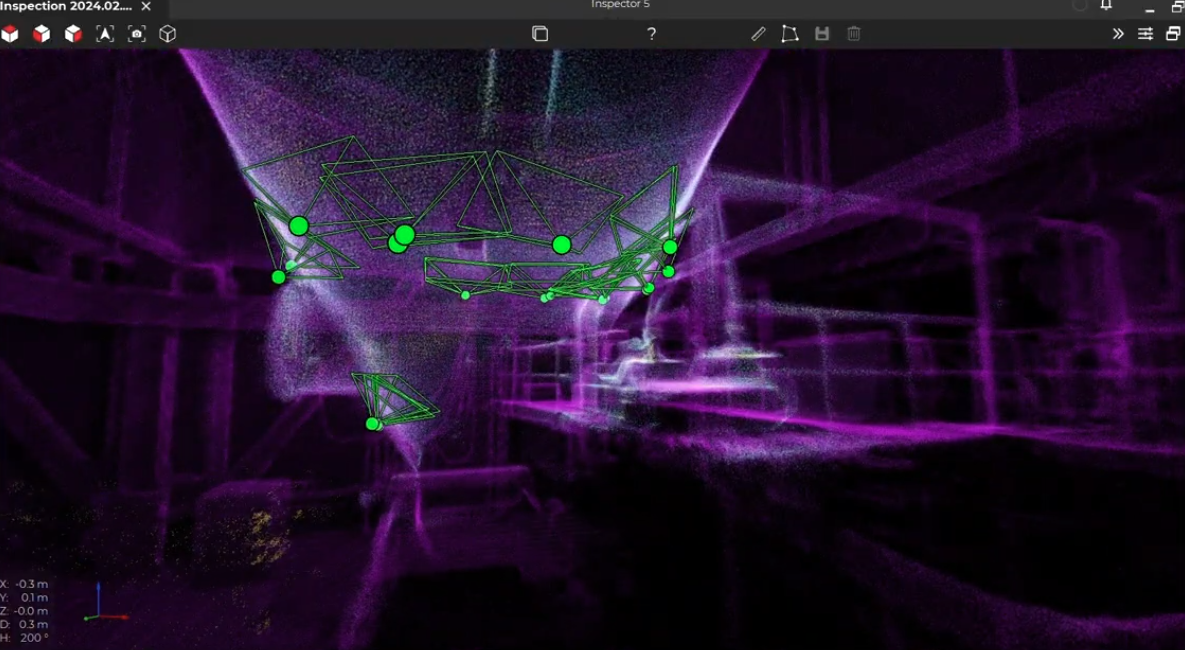

In vertical spaces, the Elios 3 flies directly into a raised bore to scan the entire surface, identifying issues and eliminating guesswork. The collision-resistant Elios can access spaces only slightly bigger than itself, gathering accurate data that was previously unavailable without drilling into the space. “It’s fantastic for us to be able to get into places that other drones just can’t sneak into,” says Gidden.

“I see [Elios 3] as being a true replacement for human eyes underground,” says Comeau.

The Glencore Kidd Operations team saves time, reduces costs, and improves safety by using the Elios 3 to perform visual inspections and mapping in GPS-denied environments. Even more benefits are realized when the data is processed and leveraged by engineers and other stakeholders, enabling better insights for decisions.

“Once you’ve collected all of your data… we head up to the surface and take all of that data up to our PCs. That’s when, for me, the fun part starts,” says Gidden.

The Elios 2, previously used in the mine, produced visual inspection data. The LiDAR-equipped Elios 3, however, combines highly accurate point clouds with visual data, taking indoor inspection to the next level.

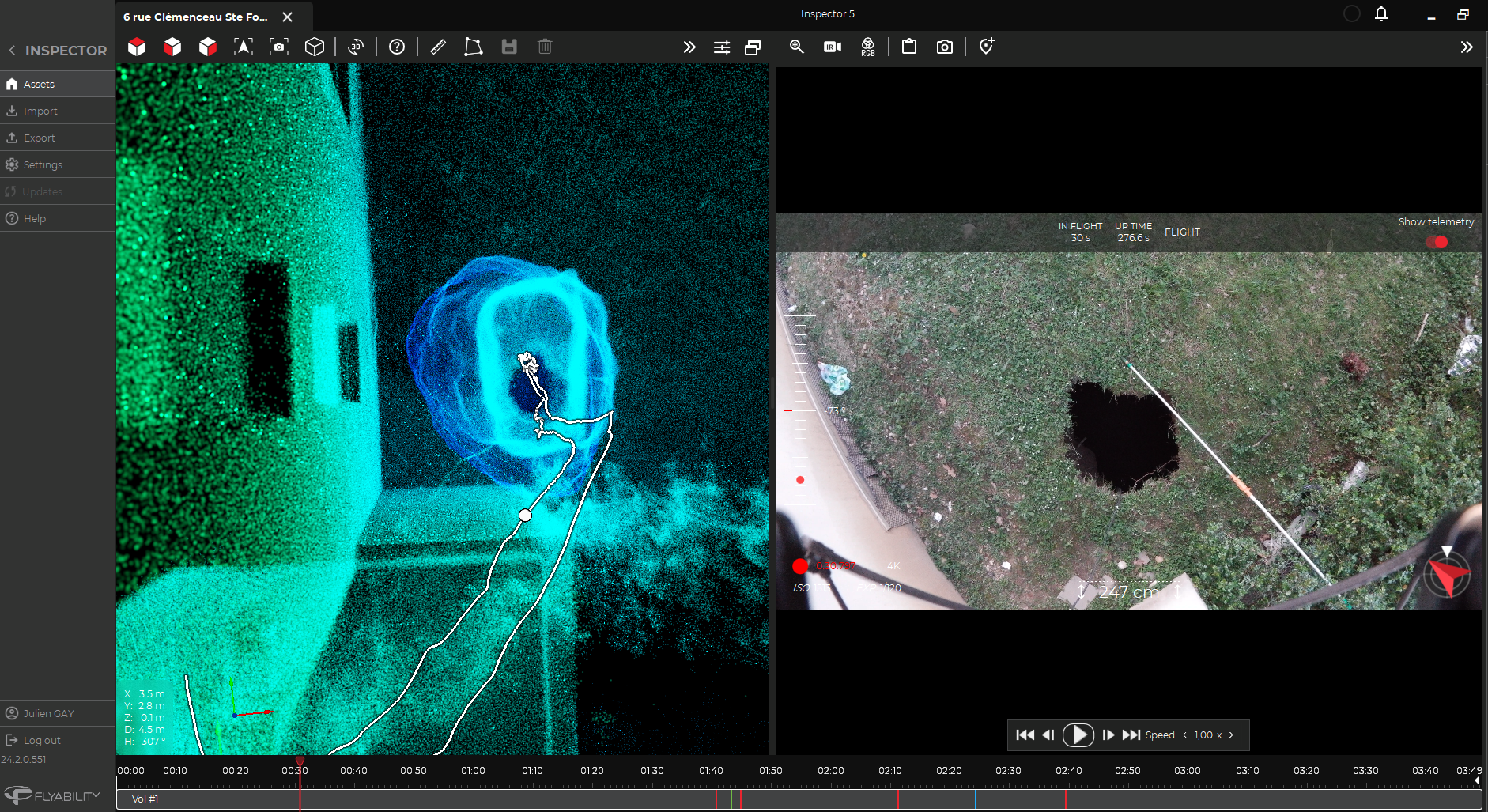

Data is processed using Flyability Inspector software. The team displays LiDAR point clouds alongside video images. “The fact that you can show someone a scan adjacent to the video itself is absolutely phenomenal because it can enable people to really understand and place themselves in that spot,” Gidden says.

Comeau agrees that the data presentation offers a new perspective and understanding of underground conditions to all stakeholders. “In meetings, we’ll bring in all of the different departments… each person is looking at [the data from] their own special viewpoint. Operations people are looking at logistics, ground control guys are looking at the ground, the geology guys are looking at some of the faults in the structures… you get everyone’s opinion,” says Comeau.

Impact of using drones for surveys

Within a single flight, Elios is able to safely inspect and collect reliable data in some of the most inaccessible places, like vertical bores and ore passes. This would typically require much longer times, expensive equipment, and sending people into dangerous spaces.

Elios offers ground engineers actionable data without going underground, allowing them to really understand and place themselves in that spot to make informed decisions. Elios removes the guessing part out of the operations.

"It can definitely cope with the environment. I've never seen areas where it's struggled with dust or lighting" - Megan Gidden

The future with the Elios 3 drone

The Glencore Kidd Operations team is leveraging the Elios 3 to optimize mining operations, moving from reactive maintenance to predictive analysis that enhances safety and minimizes downtime. By providing a wide variety of staff with drones, Glencore Kidd Operations plans to make data capture and scanning a regular part of workflows. This data can then be stored, available for reference, and enable accurate change-over-time analysis.

“E3 does almost any job we can think up for it,” says Iain McKillip, Manager of Mine Technician Services. “It goes places other drones can’t.”

“The ultimate goal of a program like this is to gather as much data as we can without even knowing if we’re looking for something… We want to deploy [E3] as we go,” says McKillip. “Then we can have a library [of data] and if we need to look at something retrospectively, we can. What did that area look like in the past? What did that look like 4 scans ago? That’s the end goal.”

Discover more about Elios in mining at: https://www.flyability.com/mining