- Case Studies >

- Bringing safer confined space sewer inspections to Sydney...

Bringing Safer Confined Space Sewer Inspections To Sydney With The Elios 3

Benefits In A Nutshell

|

Safety |

Data quality |

|

Efficiency The Elios 3 completed an inspection of a 175-meter unsupported rock tunnel with just 2 flights, completing the inspection within 30 minutes - compared to upwards of 2 hours in the past. Additionally, drone inspections require 90% less documentation or permits when compared to “manned inspections”, speeding up the entire inspection process. |

Savings Remote inspections require less time and personnel involved in the planning phase and on-site activities. This change could generate savings in the range of 50% to 70% of the total project cost. |

Metrocorp Technologies has a 30-year history of delivering complex projects and achieving outstanding outcomes for their clients. Based in Australia, they work across the country on specific wastewater, stormwater and remediation projects alongside engineering and surveying companies. Recently, they turned to using the Elios 3 to simplify their underground and confined space inspections whilst making the process safer and more efficient overall.

The Challenges Of Water And Wastewater Inspections

When working with sewers and wastewater management systems, the networks underground can be difficult to manage. Blockages, floods, and old infrastructure can all pose a challenge to utility companies. When Metrocorp gathers data for these areas, they need to collect key information while adhering to strict safety protocols.

The Metrocorp team follow strict safety protocols for sewer and confined space inspections

In Sydney, Australia, an effort is ongoing to rehabilitate old wastewater structures to extend the service life for another 50 – 100 years. This includes carefully analyzing records of what exists, mapping unused areas, and then planning maintenance and upgrades. The condition assessment is particularly challenging as it typically needs to be completed while the asset is in operation.

Metrocorp has found there are 4 key hazards to be aware of for inspecting sewers:

- Risk of fall – as many of these assets are located deep below the ground, significant falls from height can occur when accessing, exiting, or working around the access point to the sewer.

- Atmospheric conditions – due to the contents of the sewer, the internal environment often contains hazardous gases or low oxygen levels.

- Engulfment – when there is high water flow or stormwater surges, internal personnel are at risk of becoming engulfed by flowing water or wastewater.

- Roof/tunnel collapse – as some assets in Sydney can be over 100 years old, there is the potential for rock falls or even roof collapse to occur during inspections.

To mitigate these hazards, the Metrocorp team has deployed the Elios 3 drone to acquire essential data from a safe and secure distance.

In a recent inspection, the Elios 3 was used to inspect 4 separate rock tunnels (each approx. 17m in depth) that had presented advanced signs of deterioration.

A team of only 3 people completed the inspections in 1 day. A similar inspection operation conducted by tunnel traverse would involve a minimum of 7 to 10 people, and likely be completed over multiple shifts.

Using The Elios 3 For Deep Manhole Condition Assessments

Metrocorp was engaged to conduct a condition assessment of an old, deep, wastewater access shaft as part of an ongoing inspection program.

The standard operation for inspecting a 70m deep shaft involves establishing specialized deep access and confined space rescue equipment onsite. One person would then be lowered into the asset to complete a visual inspection.

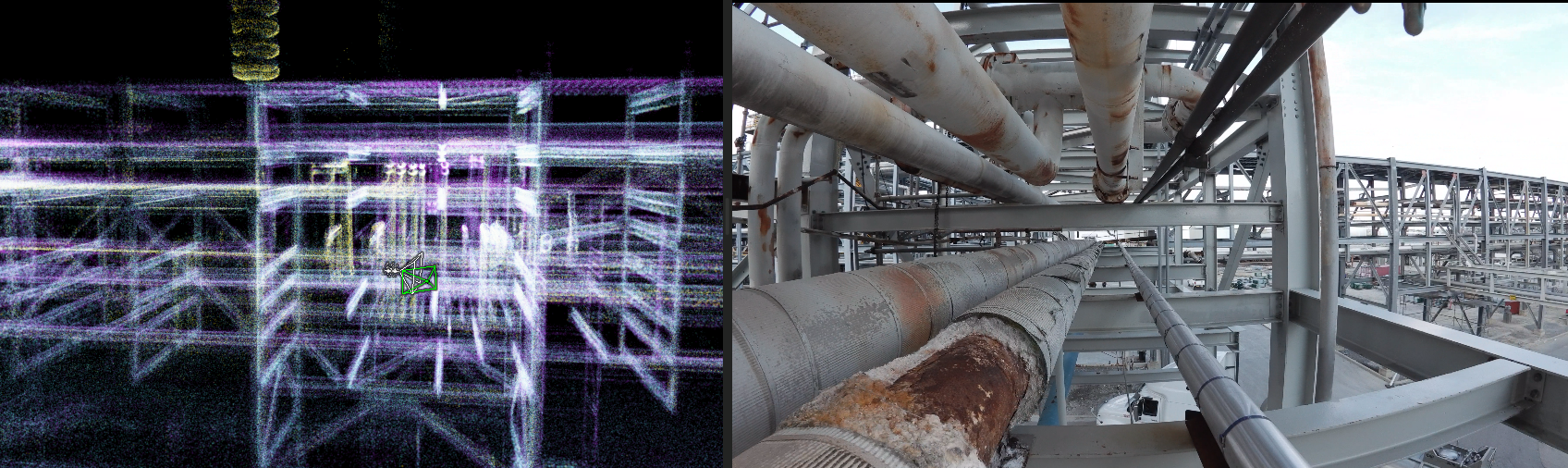

The underground tunnel inspections with the Elios 3 reduce safety risks and provide high quality data

Typically, an asset such as this one would expose the inspector to the risk of a significant fall, the hazardous atmospheric conditions associated with confined space work, and the risk of being struck by falling or dropped objects from above. The use of the Elios 3 for sewer manhole inspection not only eliminates these risks altogether but also provides superior data that can be analyzed at any time from the safety of an office.

Measurements from specific structures were taken with the Elios 3 for a better understanding of the asset’s condition and can be used by the asset owner to develop rehabilitation methods (if required).

The Metrocorp team also used the Elios 3's specialized LiDAR payload to produce a precise 3D point cloud model that was used by the asset owner when the project was completed.

Using video footage from both flights, a 3D photogrammetry model was created using specialized software. This software can replicate the asset into a 3D image, exposing its dimensions, area, and volumes within the structure. This data can be used to show engineers the exact tunnel dimensions, as well as streamline decision-making by having a clear idea of the exact condition of the structure.

It took only 2 flights to map the whole shaft structure, completing the inspection in under 30 minutes. This achievement represented a time savings of 3 hours, when compared to a normal inspection. “To enter a high-risk asset in Sydney can take weeks of planning and approval. The drone can go without the same level of scrutiny and gather higher quality data,” explains Metrocorp.

Using The Elios 3 For Sewer Inspections

The use of drones for sewer inspections is a rapidly growing application as the drones can withstand challenging conditions and reduce risk exposure. Metrocorp saw huge savings in time, energy, and improved safety through using the Elios 3.

The Elios 3 has brought huge benefits to users through heightened safety standards, improved efficiency, and higher quality data. It can reduce the cost of sewer inspections by 40% per linear meter. With the Surveying Payload released in 2023, the availability of higher quality and accuracy data has also been increased. Discover more about the Elios 3 and its specialized LiDAR payload.

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)