- Case Studies >

- Elios 3 Stockpile Measurements Improve Safety & Accuracy at...

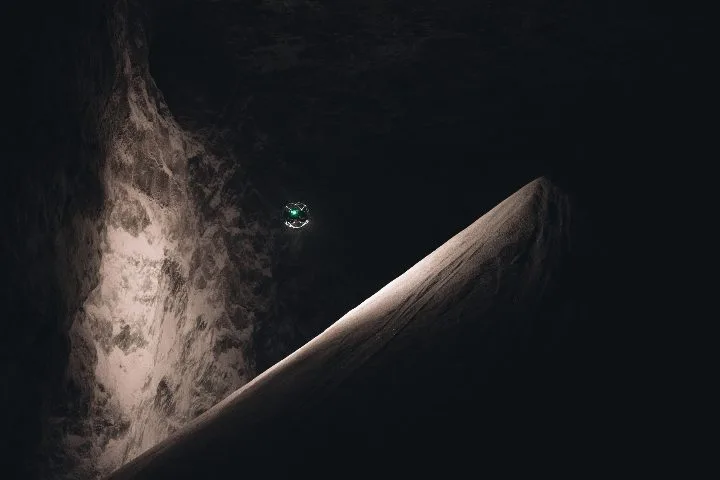

Elios 3 Stockpile Measurements Improve Safety & Accuracy At Salt Mine

LiDAR data from the Elios 3 helped mining engineers at a salt mine in Germany calculate stockpile measurements, making the process safer and more accurate.

Benefits In A Nutshell

|

Speed Calculating the volume of salt stockpiles manually is extremely time consuming. The Elios 3 significantly speeds up the process by allowing mining surveyors to stand in one location, flying the drone through an area to create accurate 3D models of the salt stored there. |

Accuracy In addition to making the process faster, the Elios 3 creates 3D models that provide greater accuracy regarding stockpile calculations than the calculations made using manual methods. |

Safety Calculating volumes manually requires surveyors to climb the salt cones, presenting dangers related to work at height. The Elios 3 removes the need for surveyors to do this climbing for data collection, allowing them to remain safely on the ground while collecting all the data they need. |

Introduction

Volume calculations are a regular part of the work done at many operations in the mining and aggregates space, where huge amounts of different materials are collected and stored over long periods of time.

These calculations help determine:

-

How much of a material is present in stockpiles within a mine.

-

How much of a material is present in storage.

-

How much of another material will be needed for backfilling empty chambers from which the extracted material has been removed. This last use helps determine the amount of material needed to fill a chamber, and it also helps determine whether the initial volume calculation for how much material could be taken out matches how much material was actually taken out.

At the moment, the way surveyors do these volume calculations is mainly manual.

In a mine, surveyors will climb large stockpiles of material and take manual measurements, an approach that is both slow and inaccurate.

In storage, surveyors will use a handheld sensor to measure the height of a stockpile. They also weigh the trucks that remove material from the stockpiles to monitor how much material goes in or comes out from each one, allowing them to track the change in size of their stockpiles. But these approaches are inexact, and lead to a general lack of knowledge about just how much material there is in a given stockpile.

In backfilling, calculations are also made based on manual data, an approach that, again, is slow and inaccurate.

Despite all these challenges for volume calculations, they are an essential function. Mines devote hundreds of hours of work hours and large amounts of resources every year to do them, knowing all the while that the resulting data will be inexact.

Customer Needs

At a salt mine in Germany, the surveying department is in charge of mapping the entire mine and depicting these maps in the mine’s plans.

An important part of their survey work is to maintain an inventory of the salt within the mine’s storage chambers.

For this reason, surveys of the salt stockpiles are done every month. The surveys require about one day (or one shift of work) for manual data collection conducted by climbing the salt piles, and one day (or one shift) for making calculations based on the data.

To collect the data, surveyors climb the salt cones and measure the height from their top to the ceiling above them. After taking these measurements, they draw the cones in CAD software, then use these drawings to calculate their volumes.

This method is very time consuming and physically intense, requiring inspectors to be in good shape so they can climb the cones. The calculations it produces are also not as accurate as those that can be obtained using data from a 3D scan.

Solution

Engineers and surveyors at the salt mine learned that Flyability was developing the Elios 3, an indoor drone that carries a LiDAR sensor and runs onFlyability’s SLAM engine FlyAware, allowing it to create 3D maps in real time as the drone flies.

Since Flyability’s indoor drones are already commonly used in mining operations, they decided to test the Elios 3 to see if it could help improve their stockpile measurements.

Using the drone’s 3D models, they hoped to improve accuracy and increase the speed of their volume calculations. They also wanted to improve safety for how these calculations were made by eliminating the need for a surveyor to climb the salt cones in order to take measurements every month.

Results

The test was a success. The surveyors were able to create high quality 3D maps of several salt stockpiles within the mine using the Elios 3, proving that the approach works.

Here are the findings of the surveyors at the salt mine:

-

Speed. Using the LiDAR sensor, surveyors were able to get enough data for each stockpile much more quickly than would have been possible if they had to climb each salt cone and take measurements by hand.

-

Accuracy. The volume calculations provided by the LiDAR data were also much more accurate than those that would have been possible using data collected manually.

-

Safety. Since surveyors didn’t have to climb the salt cones, using the Elios 3 significantly improved safety for the volume calculation work, allowing surveyors to stand at the chamber entrance and fly into it to collect the data they needed.

-

Stability & ease of use. Surveyors were impressed by how easy the Elios 3 was to fly, allowing them to go from never having flown to being able to fly and collect the data they needed within the same day.

“I didn't have anything to do with flying a drone before and I have to say, the application is really very beginner friendly. Without any experience I got right into it. It's very stable, it's got a nice feel, and also the display is really great.”

- Mining engineer at the salt mine

Conclusion

Both the engineers and the surveyors were pleased with the results from their test of the Elios 3 for volume calculations.

Given the success of the test, the surveying department is considering adopting the Elios 3 for all of its volume calculations.

Making this transition would not only save them several hours of work every month and improve their quality of data, it would also mean a significant improvement to safety in their operations. Using the Elios 3, the surveyors could not only collect data for volume calculations, but also use it for data collection in potentially unstable areas, eliminating the need for a person to enter them.

Beyond volume calculations for salt stockpiles, the Elios 3 could also help salt mine personnel improve their overall understanding of the entire mine.

The head of the surveying department at the salt mine has expressed an interest to use the drone to map the entire mine. Right now the plans they have are only 2D, but the Elios 3 could allow them to create detailed, accurate 3D maps of every part of the mine.

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)