- Case Studies >

- Using the Elios 3 drone to monitor stockpiles at a cement...

Using The Elios 3 Drone To Monitor Stockpiles At A Cement Plant

The Elios 3 was used to cut risks and inspection times for stockpile surveys - while improving the accuracy of data. This is how.

Benefits In A Nutshell

|

Safety By using a drone, the need for people to climb on top of stockpiles with a GNSS rover was eliminated, improving the safety and removing the risk of falls or stockpile collapse. |

Speed With the Elios 3, it was is possible to monitor 30 different stockpiles with just 7-8 flights, completing all data collection in under 2 hours for a large area. |

|

Scalable These surveys of stockpiles with the Elios 3 are now repeated monthly, covering piles that range in size from several hundred cubic meters to over 10,000 cubic meters.

|

Accuracy With the Elios 3’s LiDAR scans, point clouds and volume calculations can be done on CloudCompare. These measurements can be accurate to within a centimeter, and are more precise than “eyeballed” estimations.

|

Proper management of stockpiles can make or break operational efficiency at an industrial plant. An incorrect estimate of materials can lead to running out of a critical element during production, and grind everything to a halt. This incurs downtime costs, wasted time, and a general hassle for everyone involved.

However, there are several challenges for managing stockpiles. Some examples include:

-

It can be difficult or dangerous to get accurate measurements. Traditionally, it requires a person to climb over the pile with a GNSS/GPS rover, which risks a fall from height or the material moving.

-

Each site is different. Some need one-off measurements, whereas others need regular monitoring. This means there was not a “one size fits all” solution.

-

A stockpile survey needs to be efficient so it does not slow down associated work or hinder other operations.

Finding A Better Way To Measure Stockpiles By Using Drones

InspecDrone is a specialized drone service provider based in Germany, which was founded in 2018 by Simon and Susanne Kumm. Their clients work in a variety of industries, which sees InspecDrone visit sites such as cement plants, metal processing, power generation, waste to energy, and wood working. Through using drones, InspecDrones help improve safety, reduce downtime and costs, as well as provide critical data.

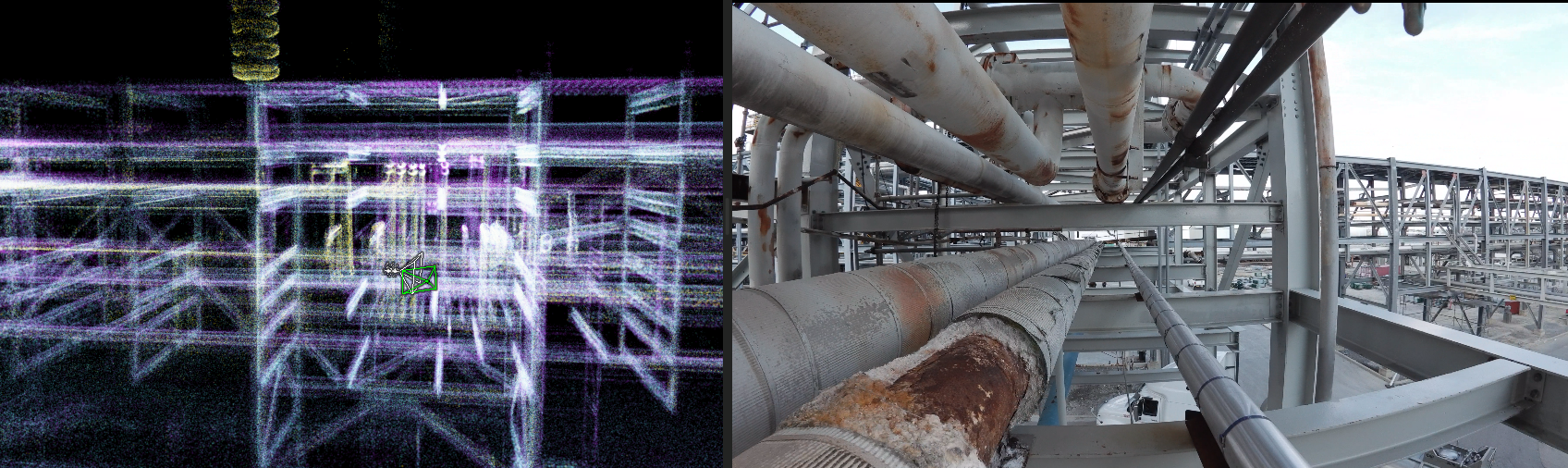

A drone inspection of the stockpiles can be done from a safe distance

One of their clients manages a cement plant. At this cement plant there are a range of stockpiles that need to be regularly measured. In the past, this client used a combination of visual estimations based on eyesight and manual GNSS measurements to determine when new material needed to be ordered, but they wanted a more reliable and precise method of measuring.

The aim was to see if the Elios 3 drone could be used to measure stockpiles, with 3 key goals in mind:

-

Better track the material being stored on-site in bunkers and piles, with the aim of using that data to plan deliveries and quantities.

-

Eliminate the need for people to walk over and on top of piles with a GPS rover, as this can be dangerous.

-

Get accurate measurements that can be reliably quantified.

InspecDrone have multiple drones, and decided that the precision of volume measurement as well as mixed location outside and inside a storage bunker called for the Elios 3 with its specialized LiDAR payload.

Using The Elios 3 To Monitor Cement Stockpiles

InspecDrone visited the site, where they assessed the area. There were multiple stockpiles there, some of which were inside a bunker and others which were stored outside. The Elios 3 can fly in confined spaces and is collision-tolerant, meaning the team were not worried about flying in interior spaces. In addition, by using this drone, InspecDrone were able to immediately achieve one of the key goals; eliminating the need for people to walk over the top of piles. The drone would be able to gather all the necessary data.

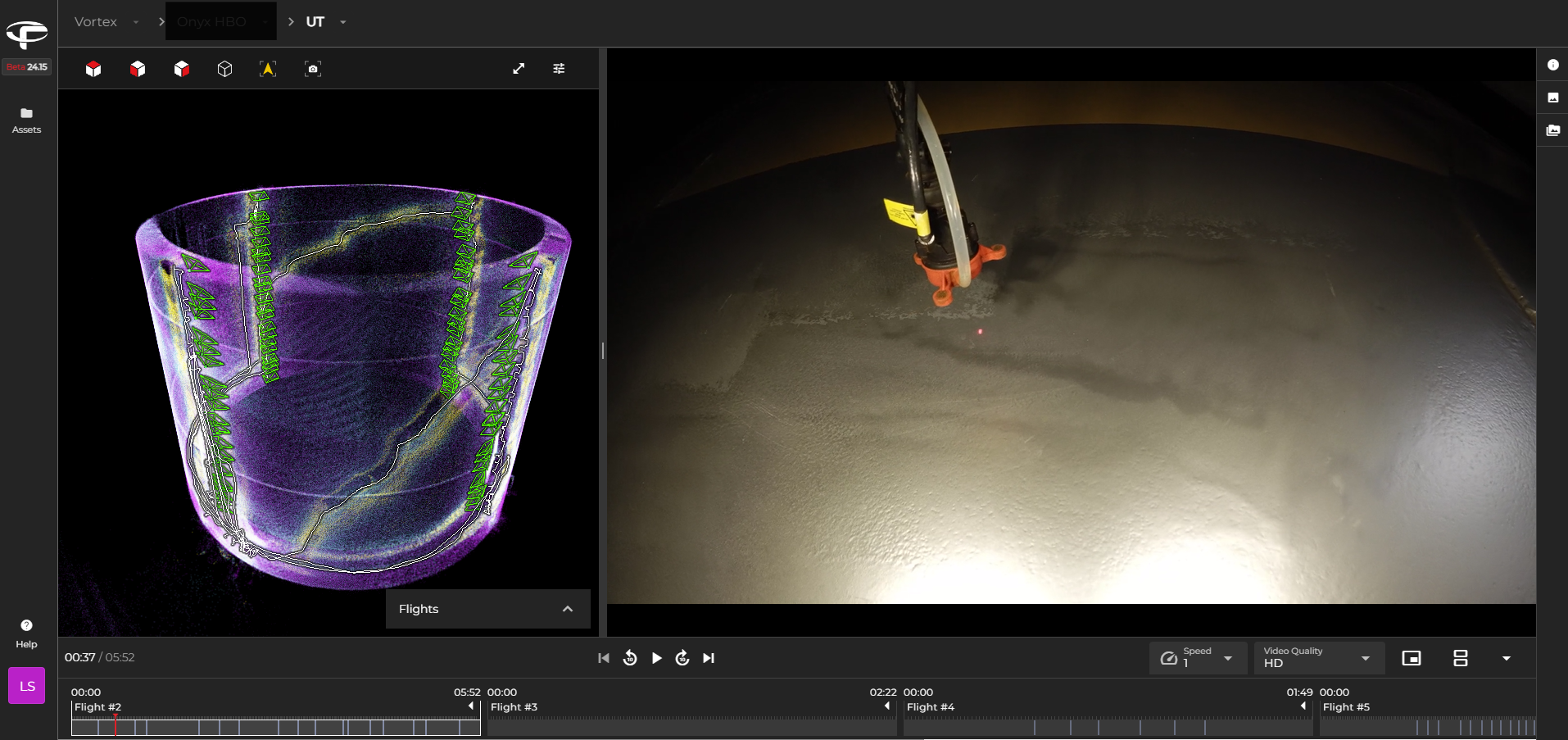

After flying the drone around the various stockpiles, the InspecDrone team processed their results in CloudCompare. The storage area had an unusual space, so Simon had to take care to account for this in post-processing. Then, he started measuring the stockpile volumes with CloudCompare. After this was completed, the results were shared with the client.

Regular Drone Surveys For Stockpiles

After this initial survey, the cement plant asked InspecDrone to come back on a regular basis to measure their stockpiles. The results from the Elios 3 had been highly accurate and provided enough detail for the plant managers to plan stockpile refill orders as well as check the current condition of stores.

Now, the total inventory of the site takes just 7 or 8 flights with the Elios 3 to cover the entire area. This includes 30 stockpiles and bunkers ranging from a few hundred cubic meters to 10,000 cubic meters. Every month, InspecDrone visit this site to survey stockpiles and compile a report for the cement plant managers.

Stockpile volumes with the Elios 3 are portrayed through LiDAR point clouds

In addition, thanks to creating these accurate models of the bunkers it is possible to determine the dimensions and available space in the area. Often there are large quantities of material that cannot be used (also known as dead stock). With the Elios 3, InspecDrone can quantify these stockpiles and use them as the zero value for future measurements - whether it is to add to the pile or calculate the remaining storage space.

Providing Frequent Drone Inspection Surveys

The combination of LiDAR technology from the Elios 3 along with its unique design made it the perfect alternative to traditional stockpile surveys. In addition, it is more accurate than “eyeballing” the levels and quantity of a pile.

With the LiDAR stabilization, InspecDrone is now expanding their services on this site to inspect the interiors of cement assets such as silos. The fast inspection with the drone allows for safer operations whilst reducing downtime and costs. Through all of this, InspecDrone are achieving the goals set out with the stockpile surveys of accurate results that enable better planning and save anyone from climbing over a material pile. In the future, with the ever improving accuracy and expanding capabilities of the Elios 3, InspecDrone expects to unlock new and exciting workflows.

The most accurate surveys with the Elios 3 are completed with the surveying payload.

.png)