- Case Studies >

- From Days of Work to a 30-Minute Flight for Oil Water...

Drone Inspection Cuts 300 Hours of Work During Emergency Shutdown

When a coal power plant in Australia had an emergency shutdown, Drone Elevation was asked to inspect the furnace with drones, and using the Elios 3, they cut over 300 hours of confined space inspection time.

Benefits In A Nutshell

|

Speed With just 30 minutes of flight, the AVC team determined the tank was ready to continue operation and the tank was only out of operation for one working day - compared to multiple days with traditional methods. |

Safety The Elios 3’s remote access eliminated confined space entry and exposure to potential hazardous gases or substances while still providing the required mission data. |

|

Access As the Elios 3 can fly safely inside the tank, it provides unparalleled access for as long as is needed by the client. It can fly up to points of interest and gather details necessary to plan maintenance, without missing any gaps and ensuring clarity of results. |

Data Quality Just 3 flights by the Elios 3 were enough to capture all of the necessary data and impress the client, who was particularly appreciative of the combined point cloud and visual inspection results. |

When oil and water mix, there’s one tool that wastewater companies turn to: oil-water separator tanks. Whether the oil is free floating, emulsified, dissolved, or in the form of suspended solids, an industrial oil water separator can filter and split the water from the contaminants.

Underground oil-water separator tanks are an effective way to include these machines in waste management processes without taking up space aboveground. However, routine inspections can be a prolonged and difficult task, requiring specialized permits for confined space entry and a complex series of steps, including taking the tank out of service, emptying and ventilating it, and testing for hazardous gases before an inspection team can go anywhere near the site.

In Canada, the owner of an underground oil water separator tank needed to conduct a thorough inspection for maintenance and updating the asset overview. It had been many years since the tank was installed and there was no clear record of the size, dimensions, and position of the tank beyond its access hatch. The client called on AeroVision Canada, a company experienced in streamlining critical infrastructure inspections, to see if they could find a safer, faster way to access and inspect the tank.

How AeroVision Canada Uses the Elios 3

AeroVision Canada (AVC) operates across Canada - mirrored by their counterpart, AeroVision Global in the USA - to deploy drone technology for industrial inspections. Their extensive experience has seen them build up a wide customer portfolio, working with oil and gas companies, electricity and water utility agencies, and as specialist consultants for engineering firms.

AVC was an early adopter of the Elios drones, using the Elios 1 soon after its commercial launch. They were one of the first companies in the world to be approved for class inspections by Lloyd's Register for vessel and mobile installation inspections at sea with drones.

Today, AVC has evolved past the Elios 1 to use the current flagship drone by Flyability, the Elios 3. Equipped with its surveying payload for LiDAR scanning and ultrasonic thickness (UT) payload for metal thickness missions, the AVC team frequently uses the Elios 3 to empower their missions. When they were asked to inspect this oil water separator, they knew the Elios 3 was the best tool for the job.

.jpeg?width=658&height=1169&name=CaseStudy3%20(1).jpeg) Confined space work requires special safety protocols and training for inspectors - but the Elios 3 can streamline this while keeping people safe through remote access

Confined space work requires special safety protocols and training for inspectors - but the Elios 3 can streamline this while keeping people safe through remote access

Why the Elios 3?

As long-term Elios drone users, AVC is intimately acquainted with the ideal scenarios to deploy the Elios 3. They knew that it could offer them remote access to the oil water separator tank, allowing them to perform a comprehensive asset assessment without requiring confined space entry.

Here are the key features that make them so confident in the Elios 3:

- Collision-tolerant design: the Elios 3 has a protective exoskeleton in the form of a cage that keeps the drone in the air even when it makes contact with its surroundings. This is ideal for tight confined spaces, such as inside a tank, where the drone is beyond the visual line of sight. It offers a layer of confidence and safety to the pilot, simplifying the mission so they can focus on data collection rather than fear crashing.

- Accurate data: as a confined space inspection tool, the Elios 3 doesn’t just offer visual data but also 3D models. Together, this meant that AVC could use the Elios 3 to deliver a close visual inspection and digital twin of the tank. This would offer the client the dimensions and asset information that had not been recorded during installation, providing a clear record and empowering quick decision-making in the case that maintenance work is needed.

- Speed of results: between the massive reduction in safety protocols required for drone entry versus human entry, and the speed of the Elios 3’s data collection, AVC turned this project around in 1 working day - an incomparable result compared to the typical days/weeks required for this work with traditional inspection methods.

AVC’s expertise in using drones for industrial inspections, combined with their knowledge and use of the best tools for the job, offers them an unparalleled edge over competitors and traditional inspection methods.

The Elios 3, seen from the side, has a protective cage as well as a LiDAR scanner for 3D modeling

Inspecting an Oil Water Separator Tank

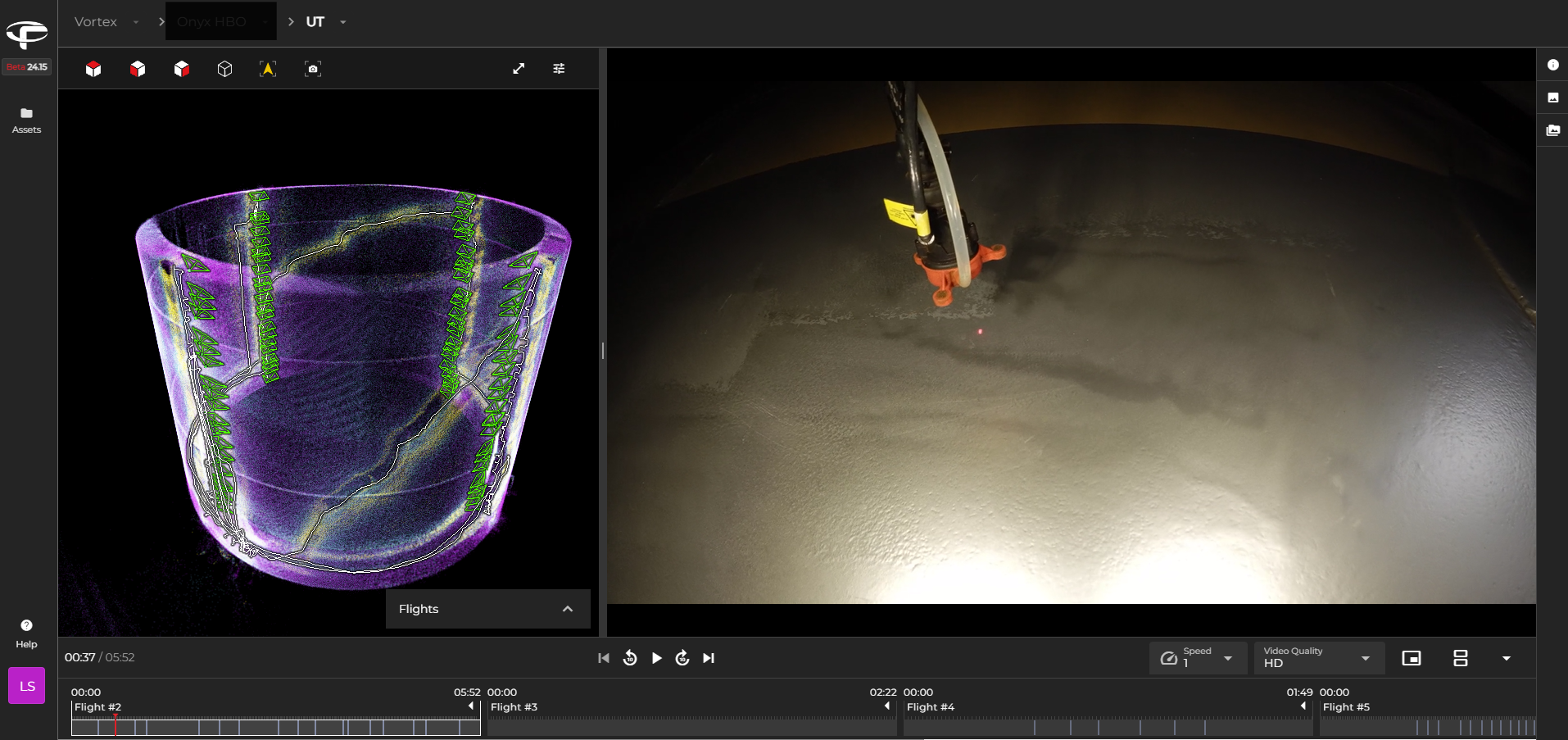

No previous drawings of the oil water separator tank existed, and the client wanted to have accurate dimensions and a general condition assessment to update their records and plan any necessary maintenance work. AVC planned to visit the site and do an exploratory flight with their Elios 3. If the client was happy with the results, they would complete the inspection and move forward. This was agreed to by the client.

As a first step, the tank was taken out of service. Immediately, the AVC team prepared the drone and flew it into the tank without the need for ventilation beforehand - something that is impossible with human entry. The exploratory flight started from the opening at ground level and explored the drained subsurface. Then the pilot presented the initial results to the client.

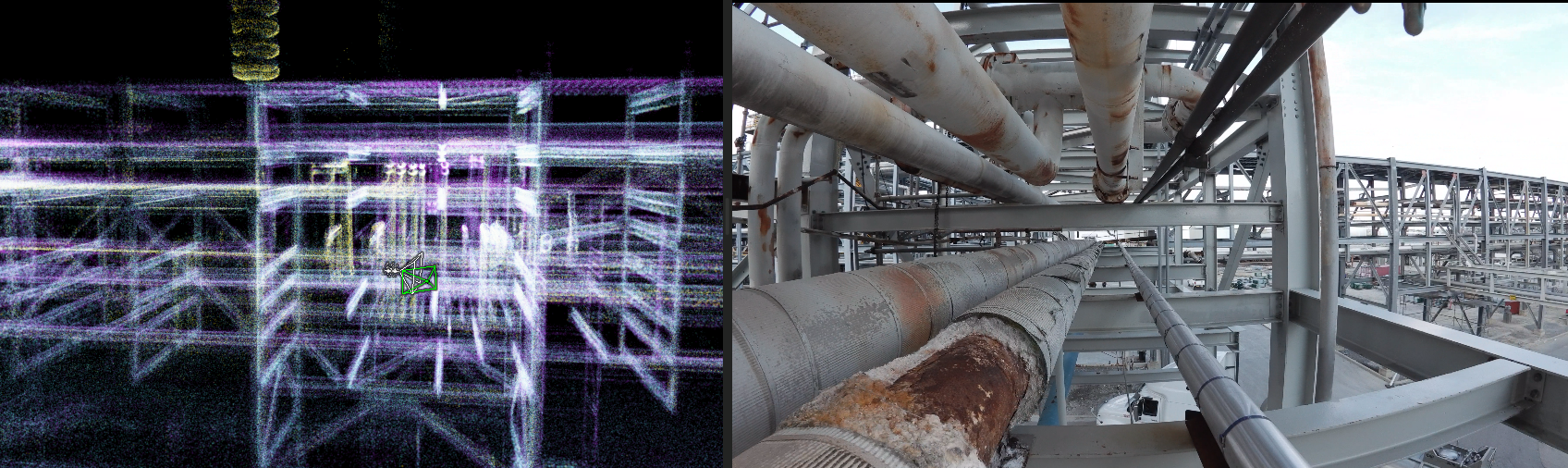

.png?width=1912&height=826&name=CaseStudy2%20(1).png)

Access from a small hatch on the ground was all the AVC team needed to deploy the Elios 3

The client was so impressed that they immediately asked AVC to complete the mission. AVC then did more in-depth close visual inspections over two more flights. In total, they flew with the Elios 3 for 30 minutes. They prepared the results on-site and showed them to the client and the assessment team. It was determined that the tank did not need any additional maintenance work and that the Elios 3’s results were sufficient for updating records. The tank was closed and put back into service. The entire process took just 1 working day.

Remote Access Streamlines Oil Water Separator Tank Inspections

What is a daunting project for traditional inspection methods was a straightforward project for the AVC team. “Nothing compares to confined space capabilities like the Elios 3,” explains one of the expert pilot team, George Kharma. With the Elios 3, the team delivered timely, actionable data in a fraction of the time the customer expected. In addition, the speed of the work and reduced safety requirements due to no human entry saved thousands of dollars and hundreds of hours of work.

A quick overview of the 3D scan taken by AVC Canada

The Elios 3’s remote inspection was quick, safe, and could easily be repeated at this site or for other tanks. A remote inspection of this nature mitigates risks to people, exposure to hazards, and the impact of human factors related to the inspection. It cut down on hundreds of hours spent on doing safety checks and assessments prior to human access without cutting down on data quality.

The customer was impressed with the quality of AVC’s results, which were shared as videos, points of interest, and a final point cloud. For the AVC team, this was yet another job well done with the Elios 3 - and a further demonstration of how expertise combined with innovative technology offers a safer, better solution for complex industrial inspections.

.png)