- Case Studies >

- Power station inspections in Hong Kong with the Elios

Power Station Inspections In Hong Kong With The Elios

Benefits In A Nutshell

|

Speed |

Cost savings |

|

Safety |

Access The utilization of the Elios 3 by CLP Power facilitates their easier access to high-rise assets, including boilers over 30 meters tall, as well as underground or confined space assets like silos or pipes.

|

Founded in 1901, CLP Power Hong Kong Limited (CLP Power) supplies highly reliable electricity to over 80% of Hong Kong’s population - which totals 7.4 million. The company operates a vertically integrated power supply business in the city, covering electricity generation, transmission and distribution, and marketing and customer services.

CLP Power is committed to providing a reliable power supply and devotes exceptional effort to ensure the smooth operation of its power generation units and auxiliary facilities. However, because of the unique and complex environment of power stations, there are limitations and challenges to traditional manual inspections.

CLP Power engineering teams researched innovative technologies and pioneered the use of drones for power station inspections since 2016. For the past 5 years, they have been working with Elios drones to streamline indoor inspections at their sites, at the same time collecting extensive data to enhance the operational safety and efficiency of power generation equipment. This helps assess their health and level of wear-and-tear, reducing the need for work at height and in confined spaces to keep operations moving smoothly. Read on for CLP Power's story.

Discovering Drones For Indoor Inspections At Power Plants

Power stations are home to large and complex generation units and auxiliary facilities with high-rising structures, large assets, as well as underground elements. As the hub of technical expertise powers the company’s power stations with essential engineering services, one of the focuses of CLP Power’s Generation Engineering Department is to explore, research, and apply suitable cutting-edge technologies to the inspection and maintenance of ongoing projects and assets to ensure that the power plants remain in good condition.

CLP Power Director of Generation Engineering Ng Ki-on recalled that in 2018 his team wanted to explore if more innovative inspection methods could be adopted to reduce the need for scaffolding during work-at-height or confined space inspections. The aim was to find an alternative that was more streamlined and could be operated internally, rather than relying on service providers.

CLP Power Director of Generation Engineering Ng Ki-on recalled that in 2018 his team wanted to explore if more innovative inspection methods could be adopted to reduce the need for scaffolding during work-at-height or confined space inspections. The aim was to find an alternative that was more streamlined and could be operated internally, rather than relying on service providers.

CLP Power has used drones to inspect outdoor generation facilities since 2016. However, outdoor drones rely on global positioning system (GPS) for navigation, limiting indoor use where GPS signals are not always available. In addition, any collision involving an outdoor drone in an indoor area containing generation facilities can damage both the device and the facilities it collides with.

Image: Director of Generation Engineering Ng Ki-on. All images in this article are credited to CLP Power Hong Kong Limited.

Recognizing the constraints, the engineering team started evaluating various indoor drone brands. Thanks to conversations with Dronesurvey Asia, the engineering team discovered the Elios drones which demonstrated the capabilities of stable, contact-free inspections maintaining a safe distance from the object without GPS. They were inspired and envisioned applying the drone to inspect boilers, fume exhaust pipes, turbine halls, and other indoor assets of the power plants.

Developing A Drone Program At A Power Plant

When the Elios 2 was brought onto the site, Ki-on’s team was interested in its potential. They set about developing workflows and plans for when and how the drone could assist the inspections.

The collision tolerance of the Elios 2 allowed for the confident operation of the engineering team even in complex environments in the generation units from indoor stockpile measurements to boilers reaching as high as 30 meters.

In 2022, when the Elios 3 was launched, the engineering team obtained the new model as they wanted to take advantage of the added combination of using the LiDAR and visual payload at the same time for more efficient inspections.

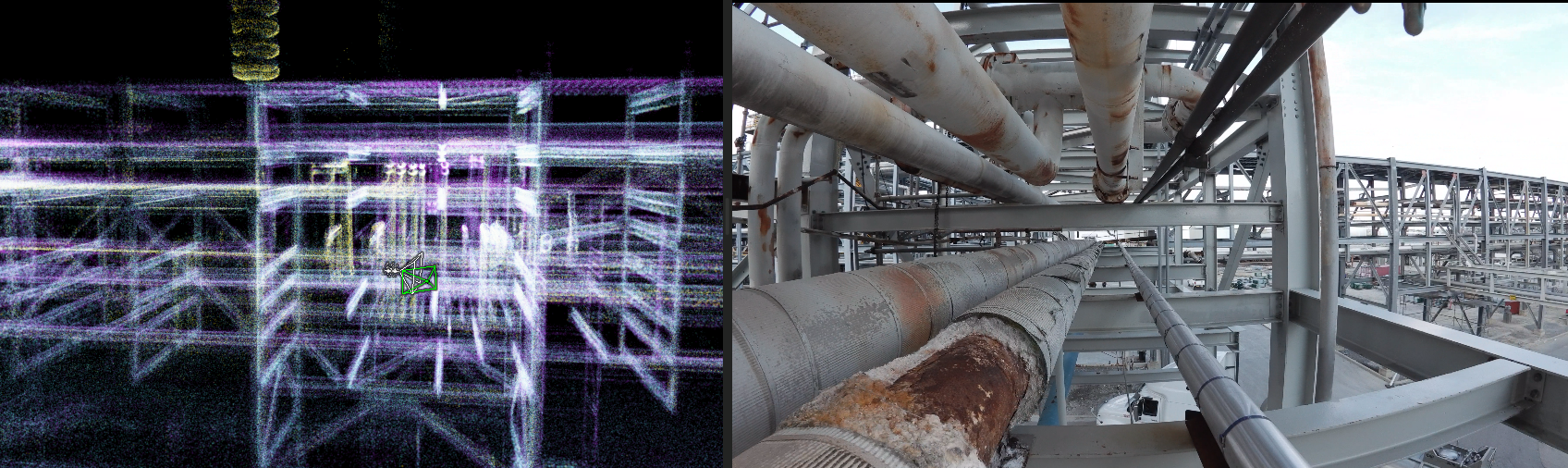

The Elios 3 at work at a CLP Power site.

Ki-on added, “When we first considered drones, some people thought we were looking for recreational UAVs for industrial tasks. But with these cage drones, we proved that drones were far from recreational toys but instead powerful tools that helped streamline indoor inspections and enhanced the safety of the works.”

A Permanent Place For Drones In Powerplant Inspections

With the inspection workflows firmly in place, Ki-on’s team now uses the Elios drones as part of inspections for assets including:

- Boilers

- Indoor storehouses

- Pump pits

- General site inspections

The Elios drones have helped make inspections more efficient and safer. For example, boiler inspections in the past required scaffolding and were time-consuming, with prolonged downtimes. Now the Elios 3 can inspect the boilers from inside and out within a day, making it easier to move on with further inspections or any maintenance work as needed. Similarly, a pump pit inspection previously required confined space works, as well as draining the water inside and erecting scaffolding. With the Elios drone, it is instead possible to complete a scan quickly without draining the pit.

An inspection with an Elios 2 drone

The engineering team has used the Elios 2 to conduct simultaneous thermal and visual inspections, and the Elios 3 to collect side-by-side visual and LiDAR data. Overall, not only are the inspections faster and safer, but they also facilitate the gathering of higher volumes of higher-quality data.

What's Coming Next?

Ki-on is excited about the future of drones in inspections. “I can see a lot of potential applications. I expect that with data collection we will soon see artificial intelligence (AI) being used to help complete in-depth analyses and save time. This will be particularly useful for people who gather a lot of data and don’t have the best systems in place to sort through it.”

Recently, CLP Power hosted a media briefing on the applications of Elios drones alongside their other tools for enhancing safety and productivity. The media coverage sparked discussions in Hong Kong, and some local government departments and organizations expressed interest in hearing more about the drone’s use in day-to-day operations.

Discover more about the Elios 3 and its specialized LiDAR payload

All images in this article are credited to CLP Power.

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)