- Case Studies >

- Analyzing a 35-meter dam surge tank with the Elios 3 in...

Analyzing A 35-Meter Dam Surge Tank With The Elios 3 In Canada

Benefits In A Nutshell

|

Safety |

Efficiency |

|

Accuracy The results from the Elios 3 flight proved the tank had not been built as-designed, so the site records needed to be updated and flow calculations redone to match the real-world data. |

Collaboration Osprey Integrity worked with rope access specialists to plan the safest way to conduct maintenance work. This collaboration kept the rope specialists safer while moving quickly with accurate data collection. |

Hydroelectric power is a highly scrutinized industry. The infrastructure is built with the best technology of the day. However, technology is constantly developing. Over time, it is necessary to go back to the hydroelectric plant and update it, and where possible, upgrade the plant output.

Taltson Hydro Plant is situated on the Taltson River, a 290 m long waterway in the Northwest Territory of Canada. Currently, it has 1 hydroelectric power station. The station has been taken offline for 6 months to enable refurbishment. It will be overhauled, including installing a new turbine, a new generator, and as-needed repair work.

Planning For Future Upgrades Of A Hydroeelctric Plant With Drone Mapping

Part of the expansive operations for the Taltson Hydro Plant’s refurbishment include the turbine being upgraded as well as the generator to increase the maximum capacity of the plant. This includes inspecting all aspects of the water conveyance system with particular focus on the penstock surge tank to understand its flow capacity and condition. This is a critical element as it is used as a damper during the normal operation of the turbine.

.jpg?width=875&height=1167&name=IMG_1634%20(1).jpg)

The Surge Tank is 35 meters tall and difficult to safely access on the inside

Data collection to assess the condition of assets would also be critical to this process. A varied and expert team was assembled to gather data in and around the plant.

Mark Horton was part of the team from Dimension Consulting brought in to digitize the hydro plant. He was collaborating with Yannick Methot of GTA Hydro, the owner’s engineer. Together they were helping to assess and plan the upgrades to the plant.

Mark Nevison of Crux Trades is a rope access specialist who was contracted to help on high access points around the site. He is the team lead of the rope specialists helping with the refurbishment.

Mark Nevison had the idea to contact Osprey Integrity, drone service provider specialists, for some of the data collection. They were particularly interested in the surge tank, which reaches 35 meters high. By using drones, they could help plan the best means of accessing any necessary work at height.

.jpg?width=875&height=498&name=IMG_1878%20(1).jpg)

Including Drones In Inspection Workflows

Osprey Integrity president Courtland Penk went to the site, which is incredibly remote - access is only possible with a small plane, rather than roads. They needed to complete visual inspections as well as LiDAR imagery. For this reason, they felt the Elios 3 was the ideal solution for the project. It could safely collect data at height and inside the confined spaces of penstocks, tunnels, and the surge tank. They particularly wanted to look at the orifice of the surge tower and then move further inside the penstock with the drone.

With the flight planned and the right tool selected, all that remained was for Courtland and his team to complete the flight.

The drone flight with the Elios 3 was incredibly quick, taking just 7 minutes to collect all of the necessary data in the 35-meter high surge tank. Afterwards, they flew the drone further into the structure, analyzing the T-Joint in the piping and tunnels, alongside visual imagery and LiDAR data collection.

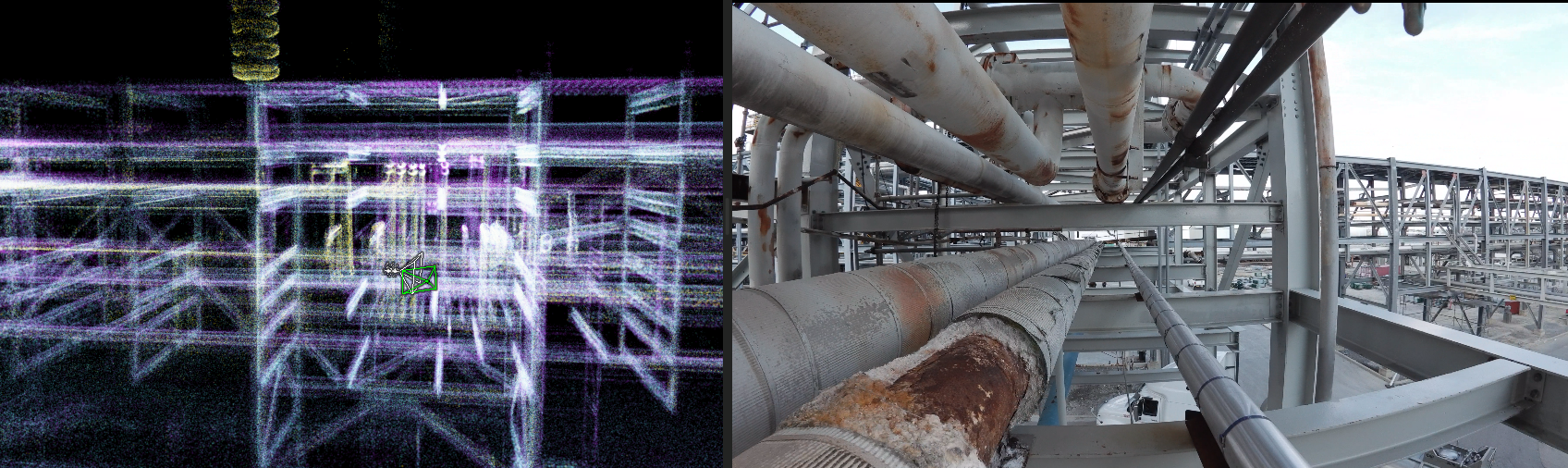

The interior of the Surge Tank had some areas of rust that the Elios 3's camera helped inspect

Results Of The Elios 3 Surge Tank Inspection

The data from the flight with the Elios 3 was incredibly useful. Cortland did initial processing with CloudCompare and Metashape before sharing it with a third-party contractor involved in the project. The extracted 3D scan was then used to perform CFD analysis on the orifice and tee joint losses for the future operation of the surge tank.

Mark N. and his team then used the drone inspection to plan access for the rope engineers. This was vital as they found that some structures in the tank they intended to use to secure the ropes had rusted through. There were also missing bolts and screws.

Watch the LiDAR and visual scans of the Elios 3 inside the Surge Tank

In addition, they found that the T-Joint had been built differently from the as-planned records, which was important information to confirm the maximum pressure capacity of the penstock with the new installations.

Impact Of A Drone Inspection

The work done by Courtland’s team in collaboration with Mark N. and the rope access specialists highlighted how rope teams can work in partnership with drone inspections to enable safer and more efficient operations.

Courtland and Osprey Integrity were able to provide more information than expected and helped streamline the refurbishment process. Soon enough the Taltson Hydro Plant will be online with the new unit, and ready to supply the local community with steps being taken for a future upgrade to a 22MW site from 18MW.

Discover more about the Elios 3 and the new surveying payload

-Jan-16-2026-10-59-56-8006-AM.png)

.jpg)

.png)