- Case Studies >

- Pressure Vessel Inspection

Pressure Vessel Inspection

Operating and maintaining pressure vessels presents considerable health and safety concerns for the Energy industry. Consequently, the regularity of maintenance inspections is to avoid leaks or explosions, this requires extensive preparation and caution by human workers.

Current approaches to evaluating pressure vessel integrity are through Non-Destructive Testing methods such as observing deterioration indicators and visual inspection. Preliminary visual inspection is a fundamental aspect of the process, other NDT methods such as ultrasonic thickness measurement are compliments to an overall assessment. The larger issue at hand is the extensive training and preparation needed for accessing and inspecting these confined areas, specialized permits, presence of multiple trained personnel, rescue teams and ventilation are a few aspects that add to the costly nature of pressure vessel inspection. Shell states that “98% of the costs are related to EHS and preparation, only 2% to the inspection itself”, which emphasizes the need for a solution that is able to perform the inspection and reduce costs related to preparation and risk.

|

Ventional Inspection Methods - Robotic Arm |

Unmet Needs - Avoid confined space access |

WHILE DOWNTIME IS REDUCED, INSPECTION PERSONNEL ARE ABLE TO CONTROL THE DRONE REMOTELY OUTSIDE THE STRUCTURE, AVOIDING THE RISK OF INJURY.

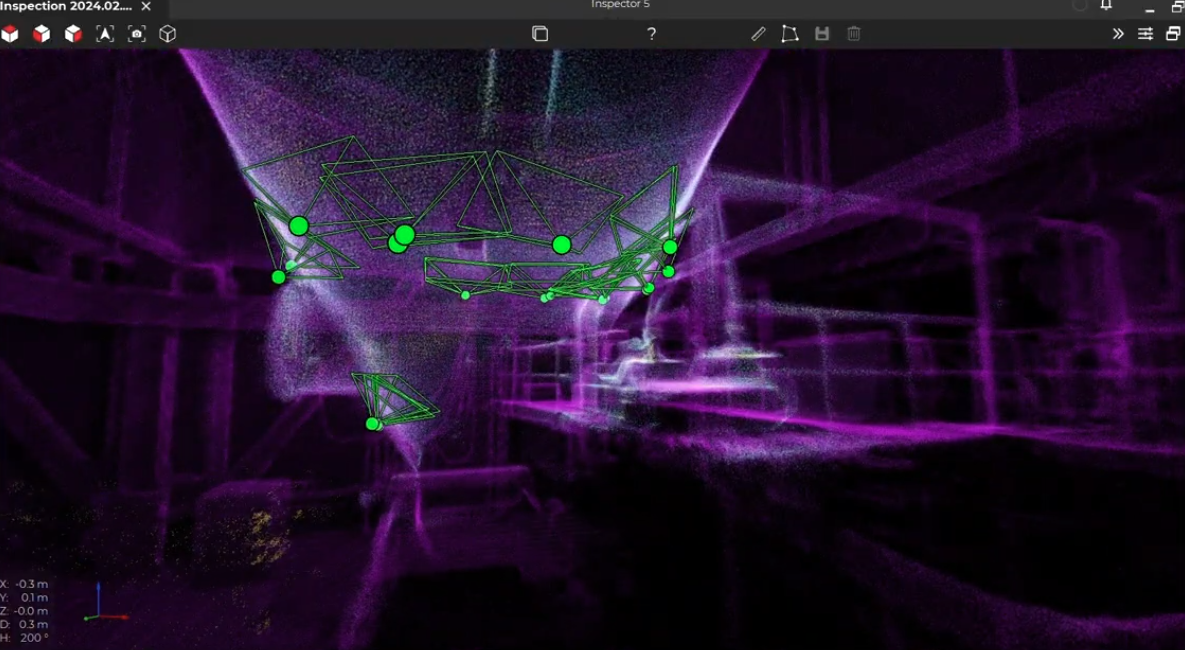

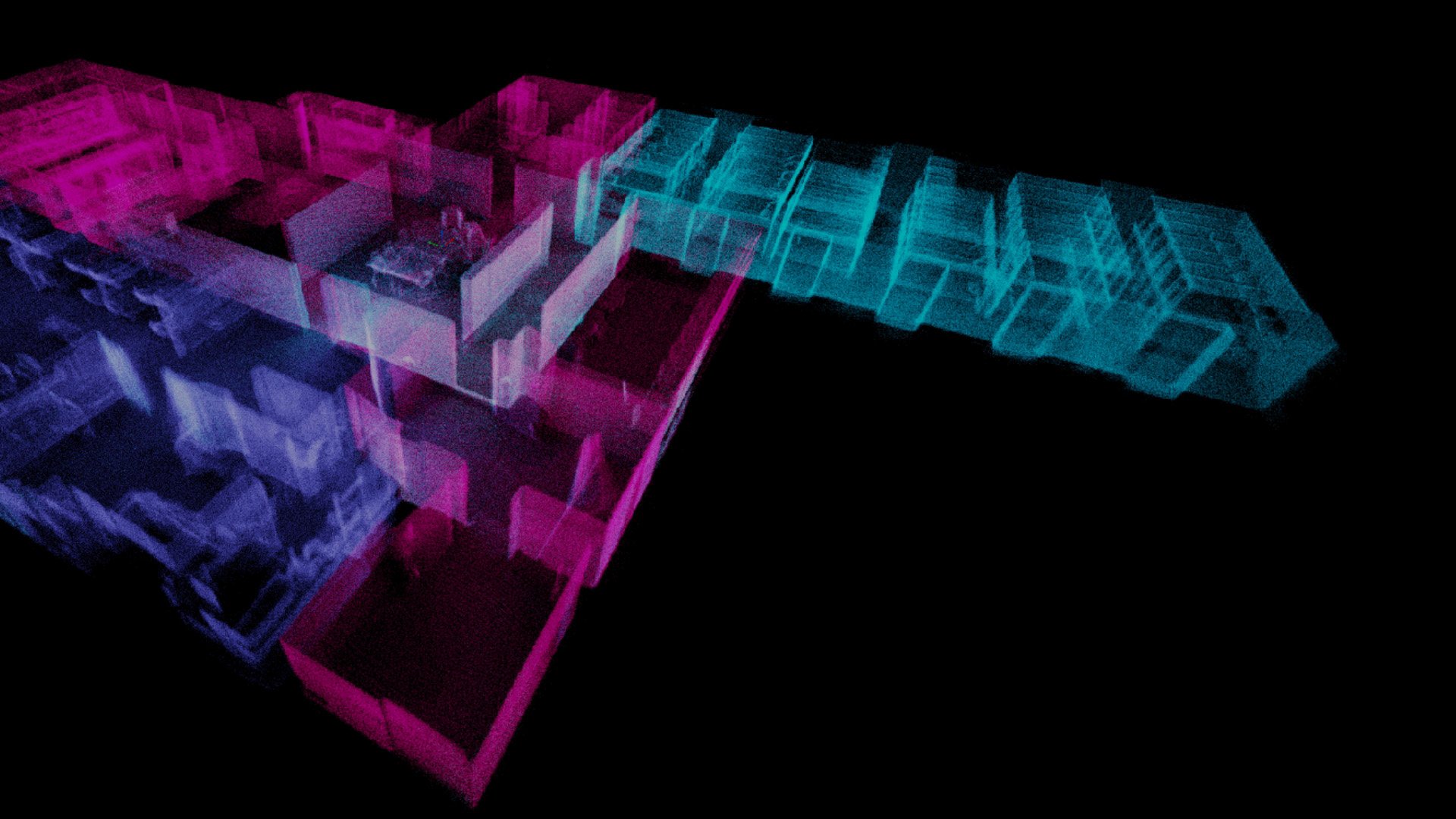

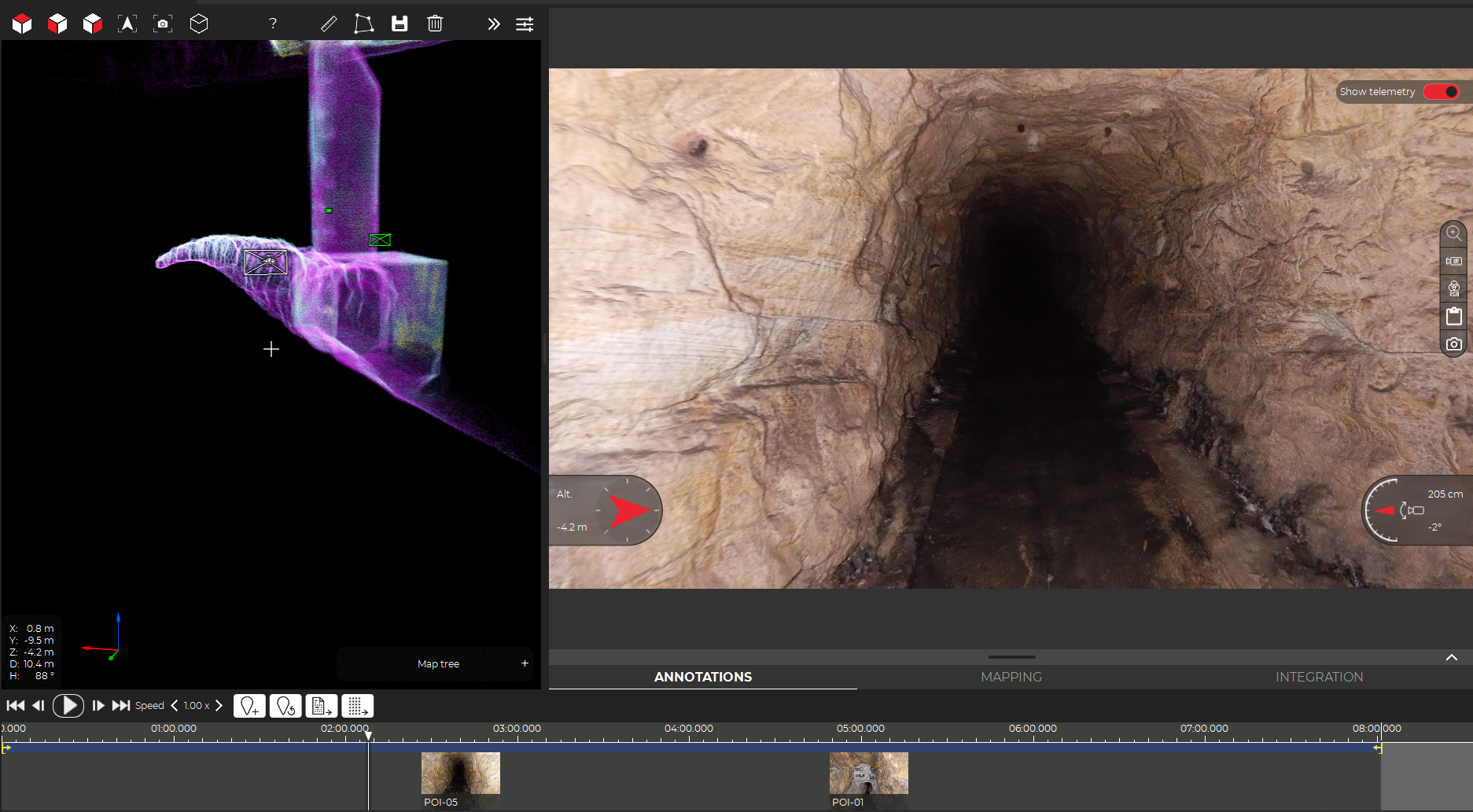

Practical robotic solutions exist for pressure vessel inspection; this includes a controllable robotic arm or magnetic-wheeled robots. However, most are limited by their locomotive capabilities when faced with obstacles or different environments. Flyability’s collision-tolerant UAV Elios is designed to reflect off obstacles with an external rotating cage, the same mechanism protects any human operators from harm.

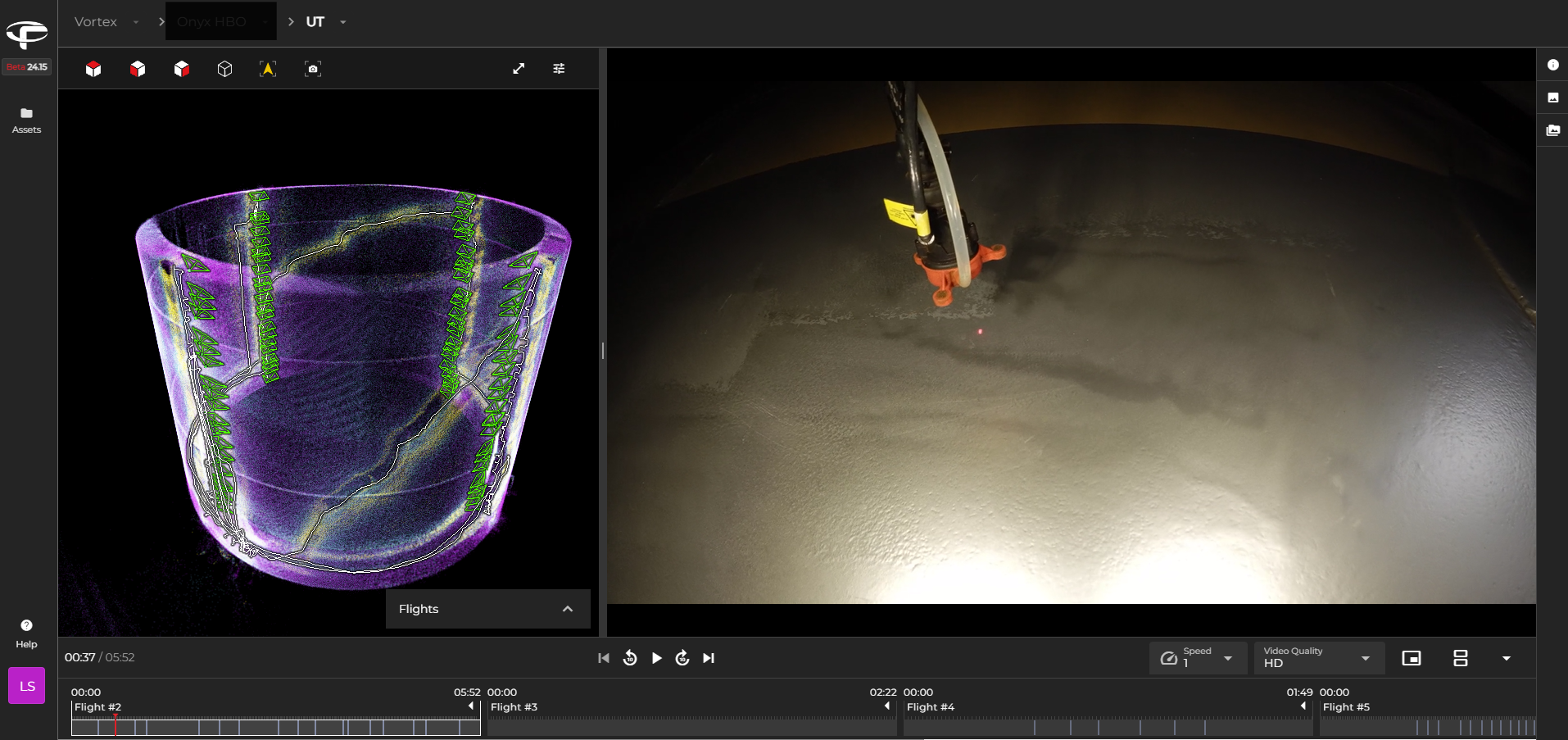

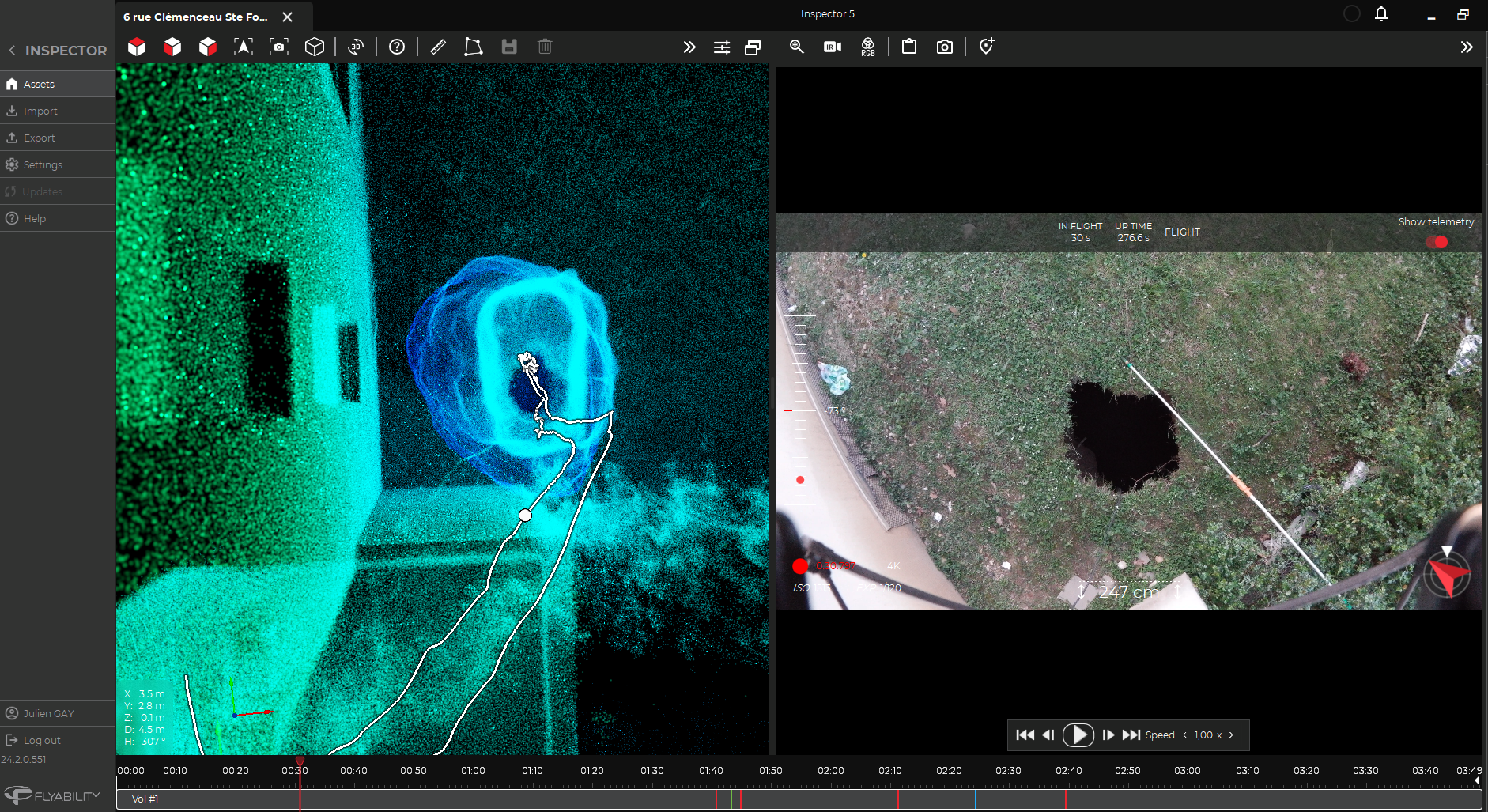

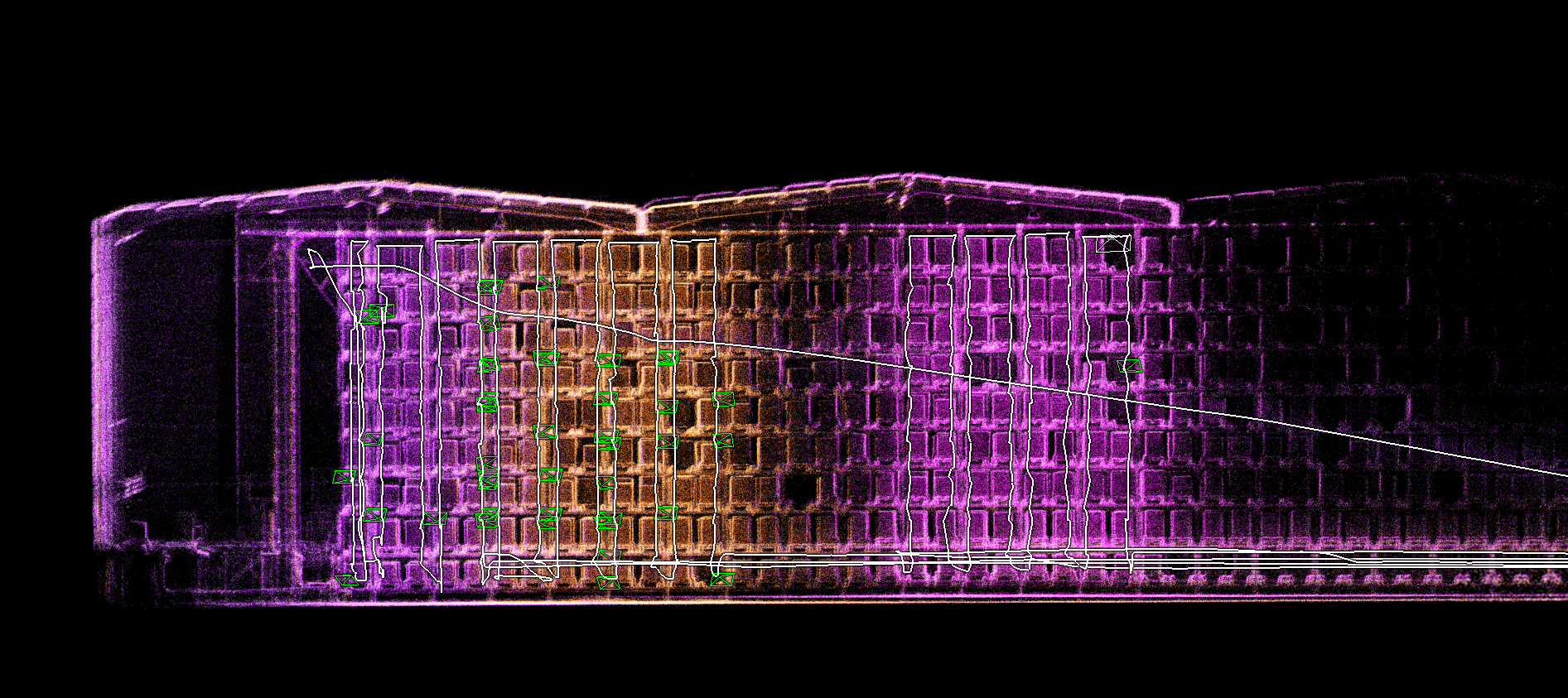

A pilot test was organized in collaboration with Chevron’s energy sector, whose objective is to prevent all human entry into confined areas by 2020. Flyability performed vertical and horizontal pressure vessel inspections. While one of our pilots was controlling the drone itself, another adjusted the live video transmission to ensure the best quality material, even in difficult lighting situations. When in contact with structures, it transmits visuals at 0.2mm/px resolution, in being able to adjust the ISO+, exposure time and LED intensity, assuring the most accurate close-proximity visuals.

To ensure downtime is reduced during our inspections, Elios can be deployed in under a minute and the batteries exchanged in under 30 seconds. inspection personnel are able to control the drone remotely outside the structure, avoiding the risk of injury, reducing overall asset downtime.

|

Mission Achievements - Complete inspection of vertical and horizontal pressure vessels |

Elios Benefits - No confined access required |