- Case Studies >

- Inspection of above-ground hydrocarbons and chemicals...

Inspection Of Above-Ground Hydrocarbons And Chemicals Storage Tank

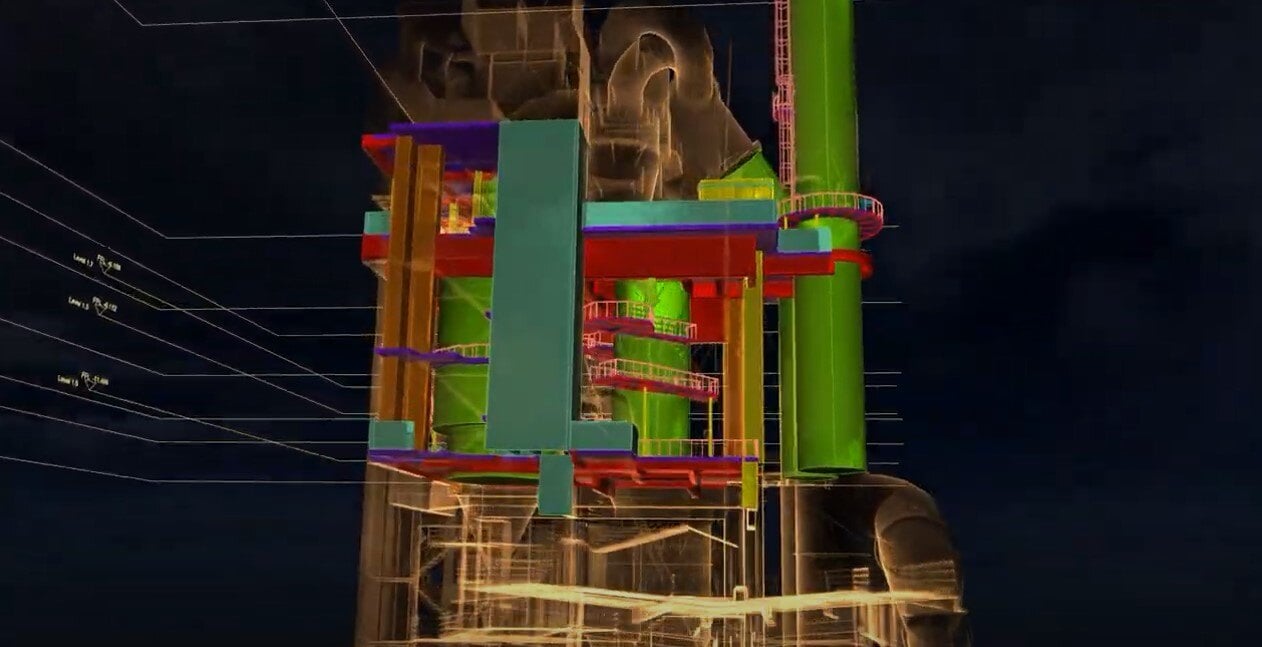

TAU AG, an asset manager in charge of a tank farm in Muttenz Switzerland for the BP and Avia oil companies, required the internal inspection of above-ground hydrocarbons and other chemicals storage tanks. Elios, the world’s first collision-tolerant UAV, provided them with a safer, faster inspection method and a greater quality of data than they had ever been able to gather using rope access, scaffolding, or visual inspection from the ground with binoculars.

Customer Need

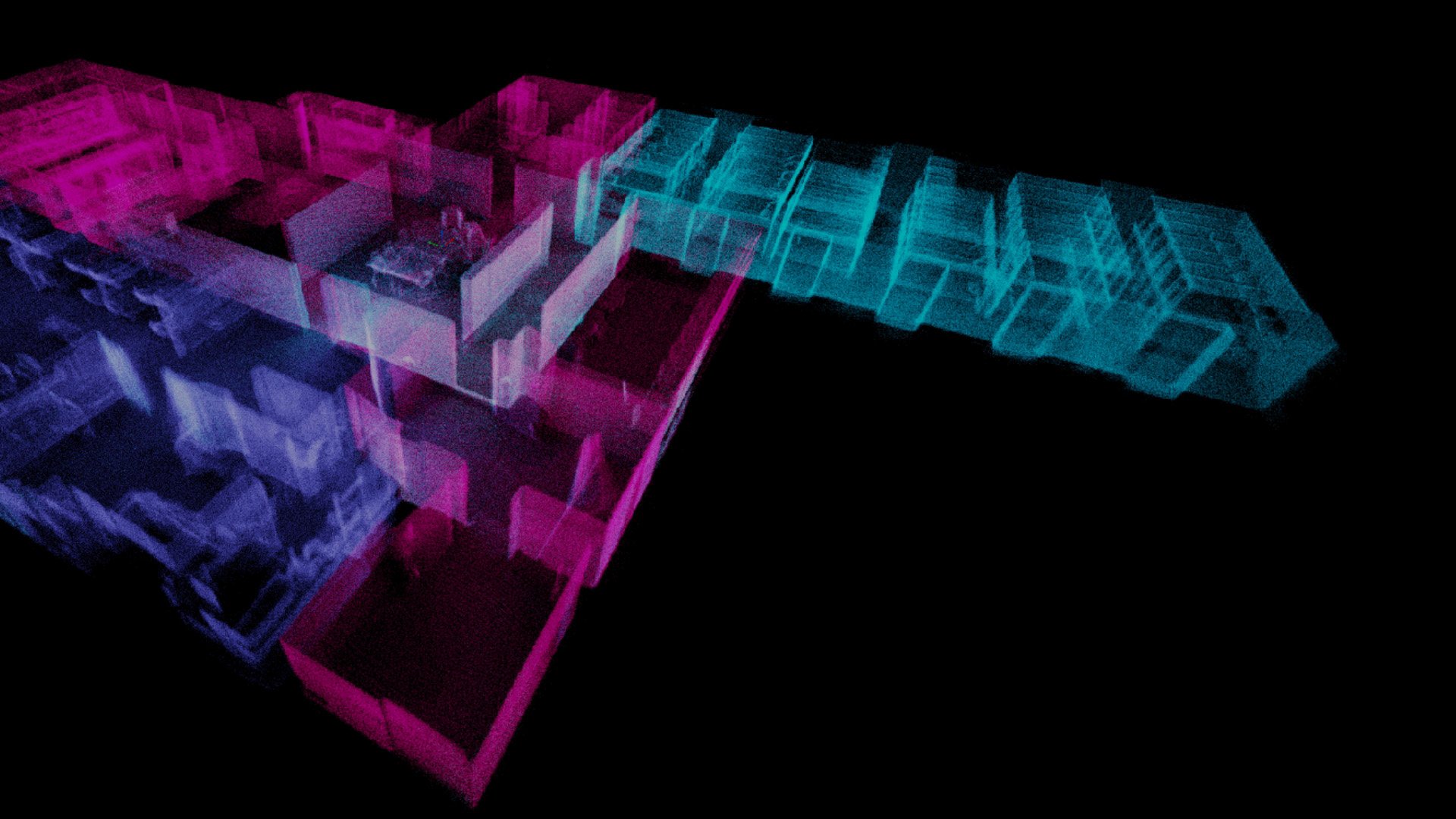

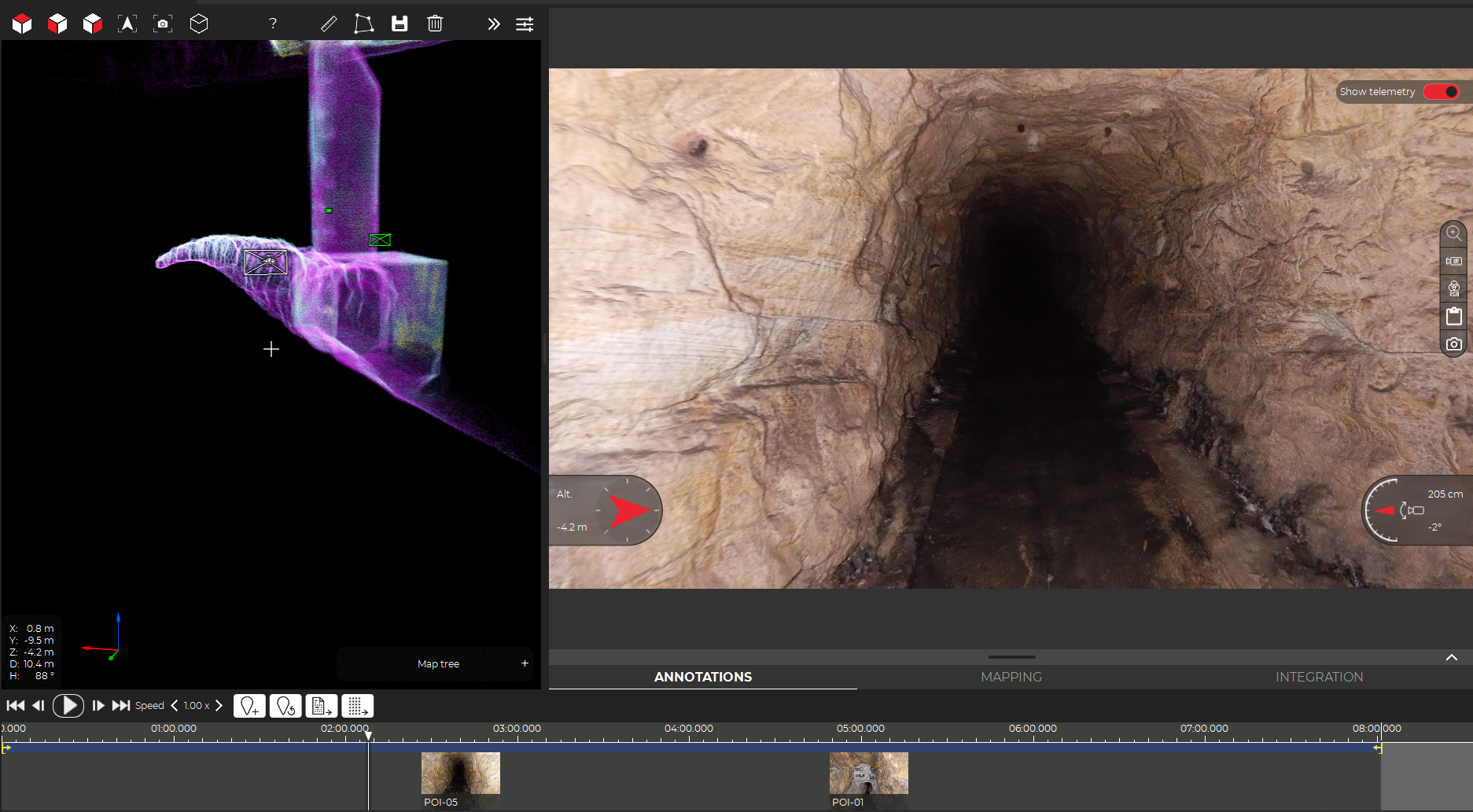

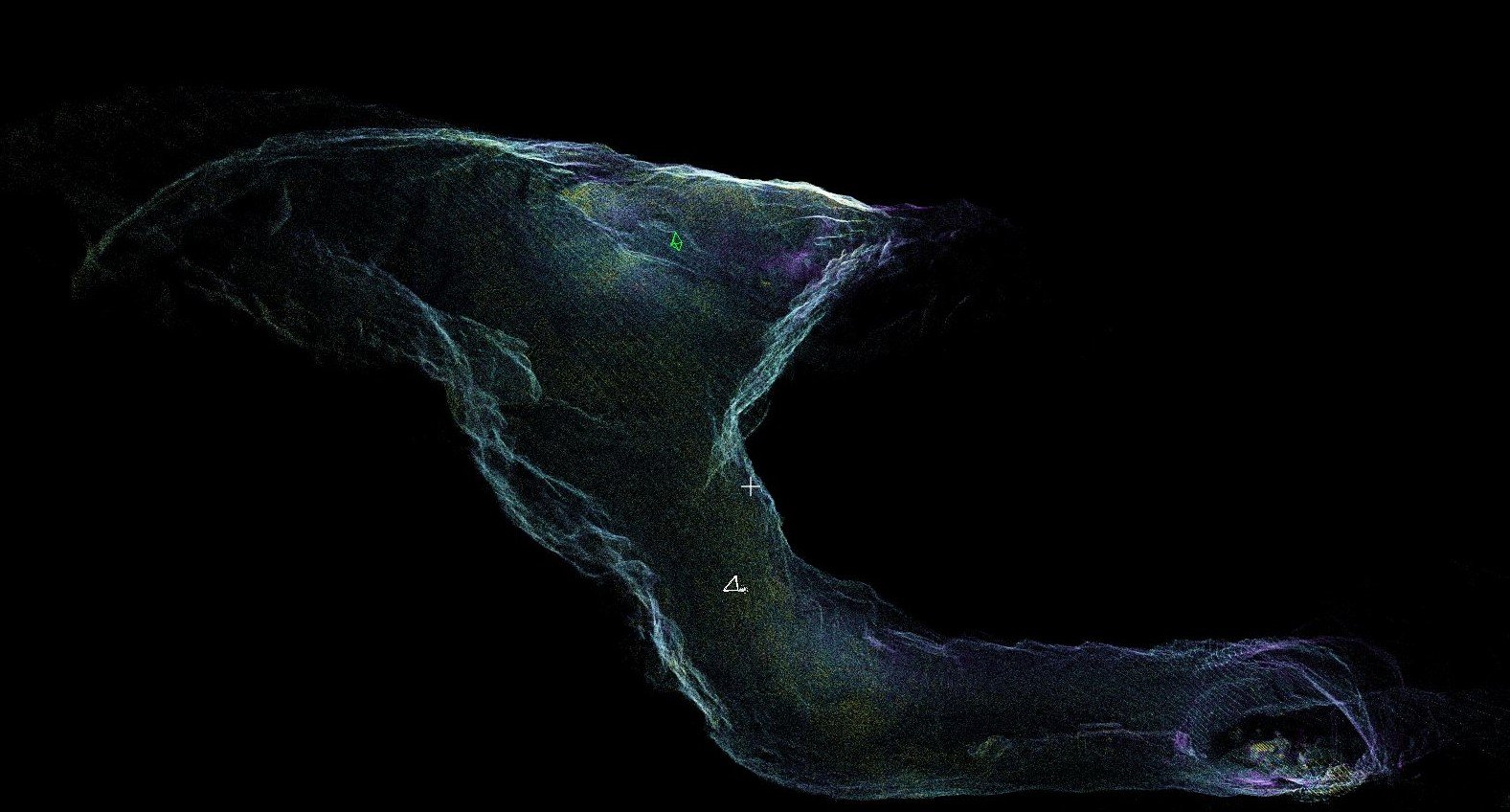

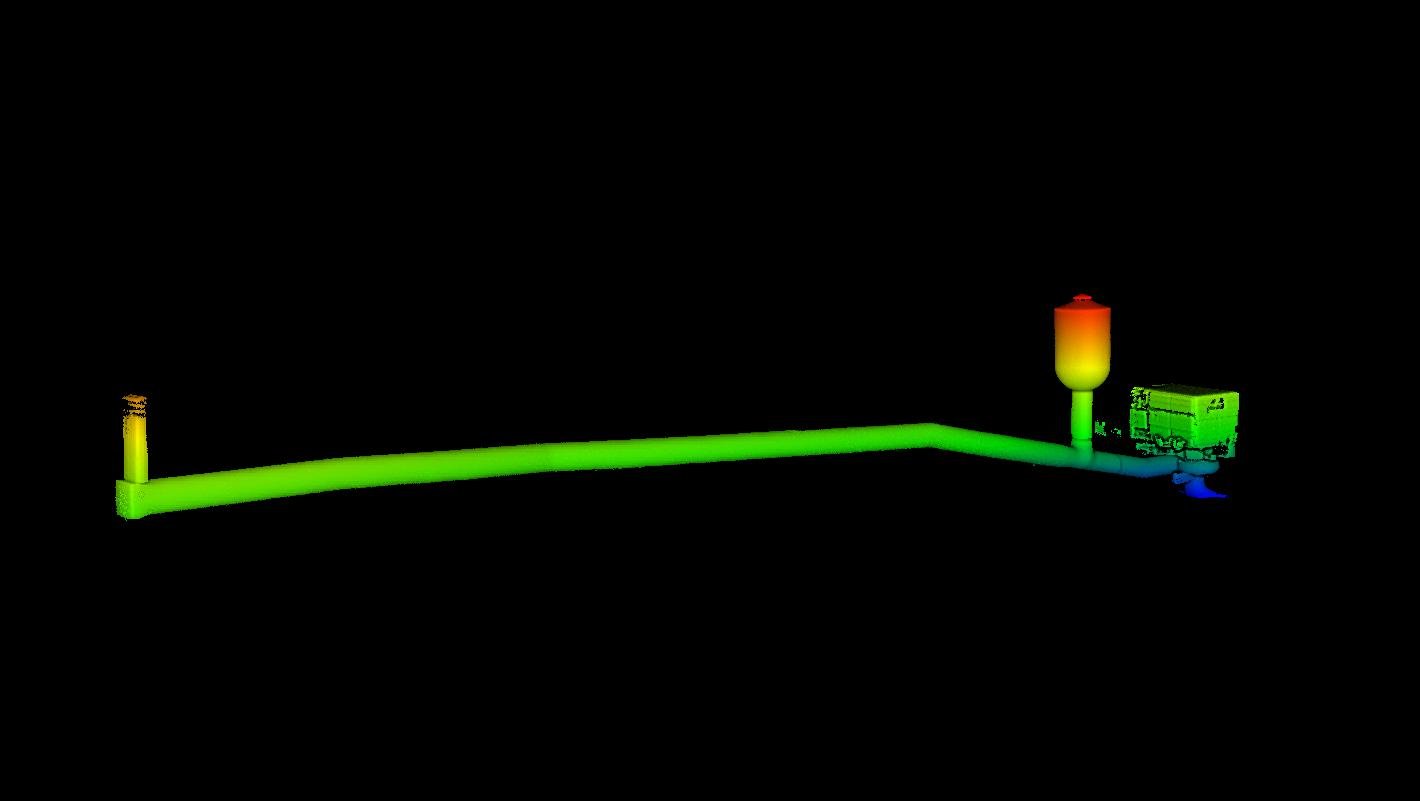

Every 3 – 15 years, depending on the substance they have contained, TAU AG performs a thorough inspection of each storage tank. After having been properly cleaned, a tank is inspected following a procedure which includes the visual inspection of fire protection piping, overfill protection, gaging system, roof pre-determined points as well as a general visual inspection of the roof. At 25 meters above ground, in pitch-dark conditions, these inspections require working at height and implies having humans entering the inner confined space of tanks. Usual methods such as scaffolding or rope access are costly and time-consuming. With these aspects in mind, TAU AG requested the intervention of Flyability and Elios for the inspection a 25m tall, 18m diameter fixed-roof storage tanks.

Solution And Process

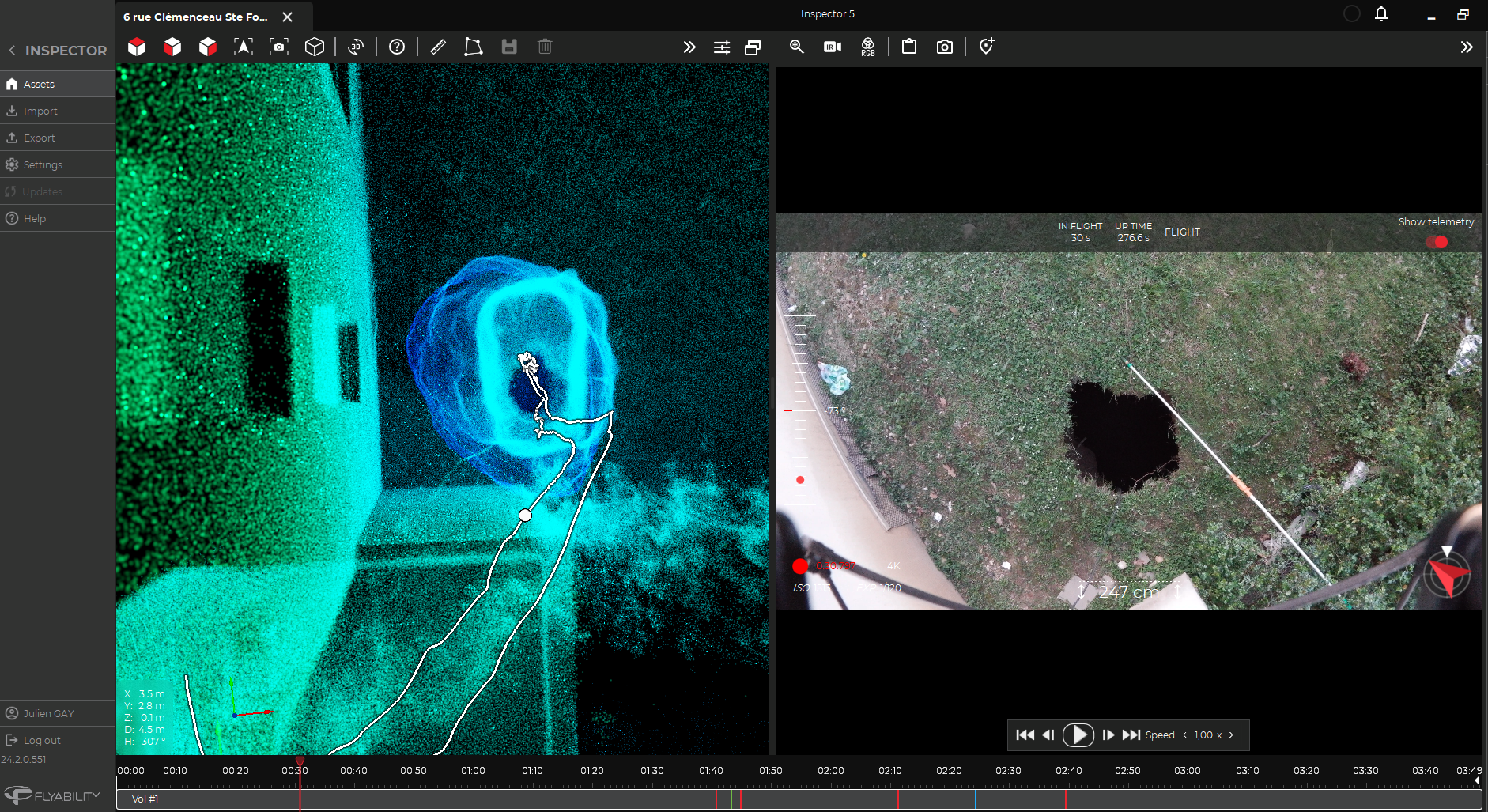

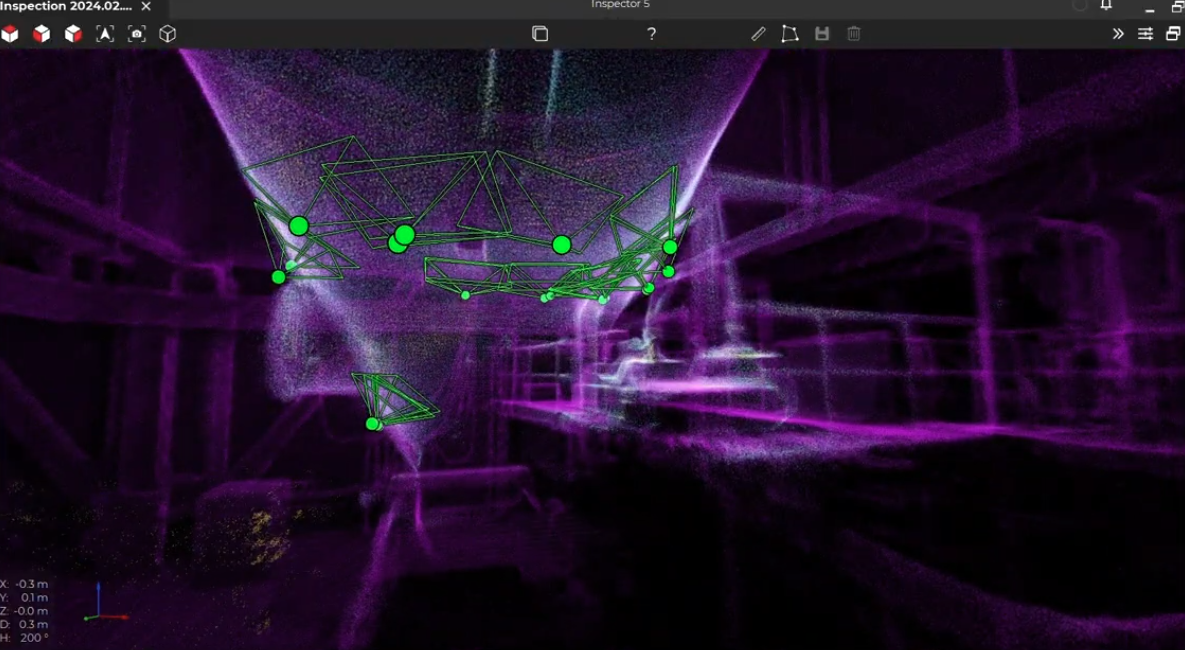

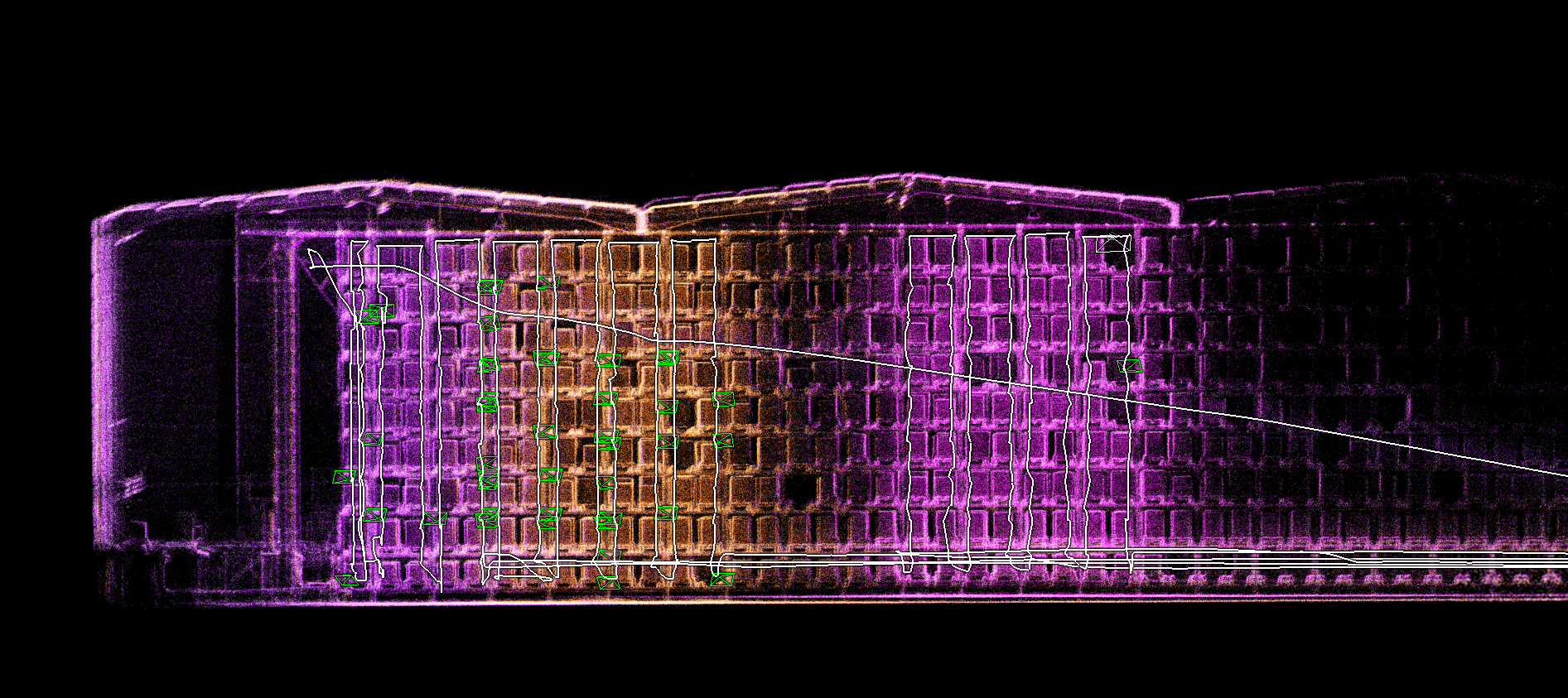

Between five and ten flights with Elios, each flight taking about ten minutes, were necessary to complete the inspection of a single tank. The tanks being cleaned and degassed, the pilots decided to enter the tanks to fly the drone, however, inspections could have been performed entirely from the outside of the structure. The fact that Elios is collision-tolerant allowed it to navigate safely, directly in contact with the walls of the tanks when required. Thanks to its powerful onboard LEDs, the inspection of the tanks with Elios did not require the installation of any additional lighting source.

Results

All structures of interest were inspected in less than two hours after deployment. The visual gathered with Elios proved the fire protection piping to be in excellent condition, the welds and overall roof corrosion conditions were satisfactory. With over 100 tanks to look after in the tank farm they manage, TAU AG is now in a position to increase the quality and level of documentation of the data generated during inspections. Most importantly, the company keeps its workers out of harm’s way and has lowered the cost imputed to inspections.