Wondering how indoor drones are being used in the chemicals industry?

The primary way they are being used is to collect visual data remotely during internal inspections.

Below we'll cover information highlighting all the different use cases you'll find today for indoor drones in the chemicals industry, including:

- Key use cases for indoor drones in the chemicals industry

- Case studies featuring the use of indoor drones in the chemicals industry

Key Use Cases for Indoor Drones in the Chemicals Industry

Here's a list of the most common assets where inspectors are using indoor drones to support their internal inspections in the chemicals industry, including notes about what inspectors are looking for and doing when inspecting them.

PIPE RACKs, CABLES, and CONDUITS

Flying between indoor pipe racks, cables, and conduits in a production facility to check the integrity of welding and detect potential leaks.

FIBERGLASS STORAGE TANKS

Checking the walls and welding of a fiberglass-made acid-containing tank at a chemical plant.

SUCTION DUCTS

Flying inside suction ducts, from bottom to top, inspecting welding and checking for product build up on the walls and on the dust collector.

STORAGE SILOS AND BINS

Checking actual cleanliness and assessing the amount of remaining product in a recently-cleaned soda ash silo. Looking for product build up as well as evaluating the integrity of the gauging cable in storage bin.

FERMENTER TANKS

Increasing the quality of batches by systematically inspecting the shaft and blades of fermenter tanks in an enzyme production facility.

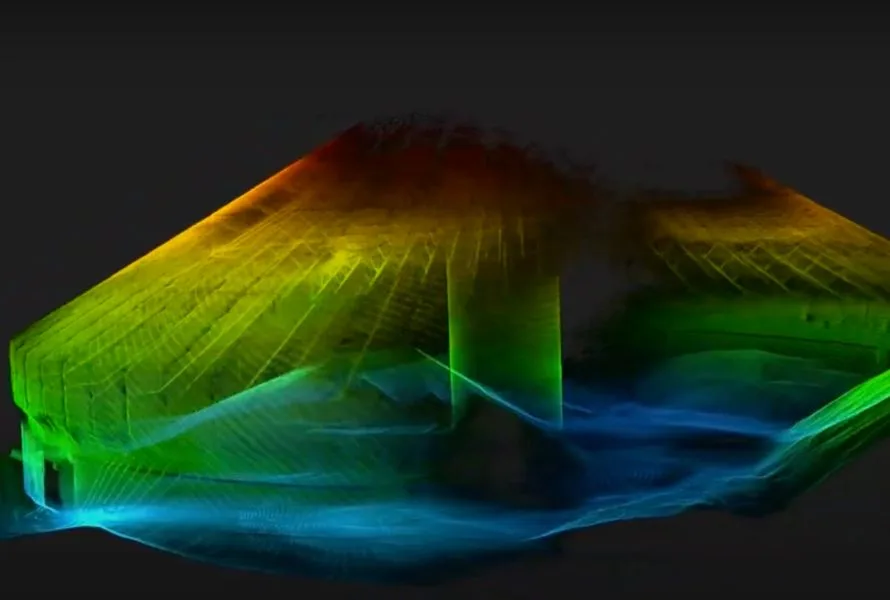

PRESSURE VESSELS / STORAGE TANKS

Inspecting decommissioned pressure vessels and storage tanks at a chemical facility.

HEAT EXCHANGERS

Looking for clogging in the tubes of a heat exchanger at a soda ash plant.

Chemicals Industry Case Studies

Want to learn even more about how indoor drones are being used in the chemicals industry?

Read these case studies to learn the details of specific missions performed with indoor drones in the chemicals industry.

INSPECTOR 3.0 HELPS SAVE HOURS OF WORK LOCATING DEFECTS IN A HYDROGEN REFORMER

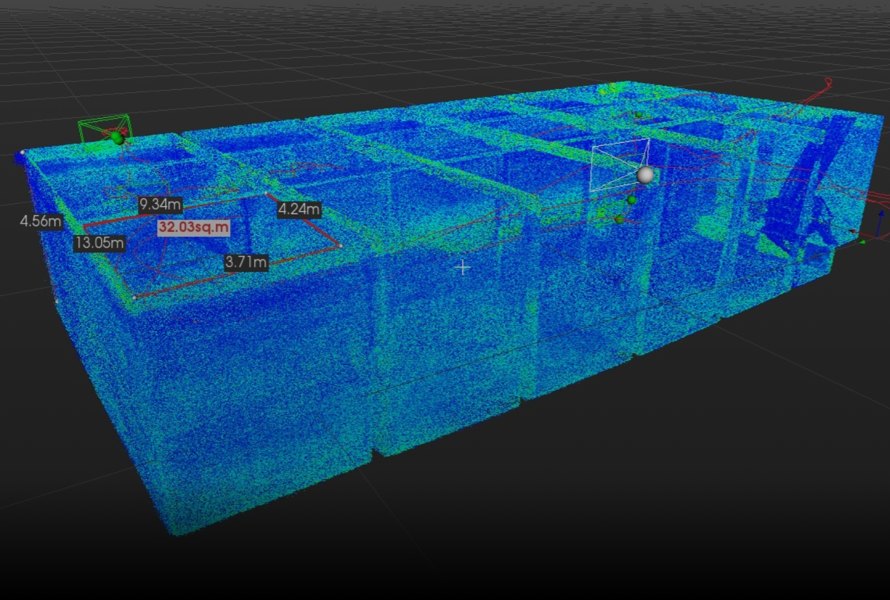

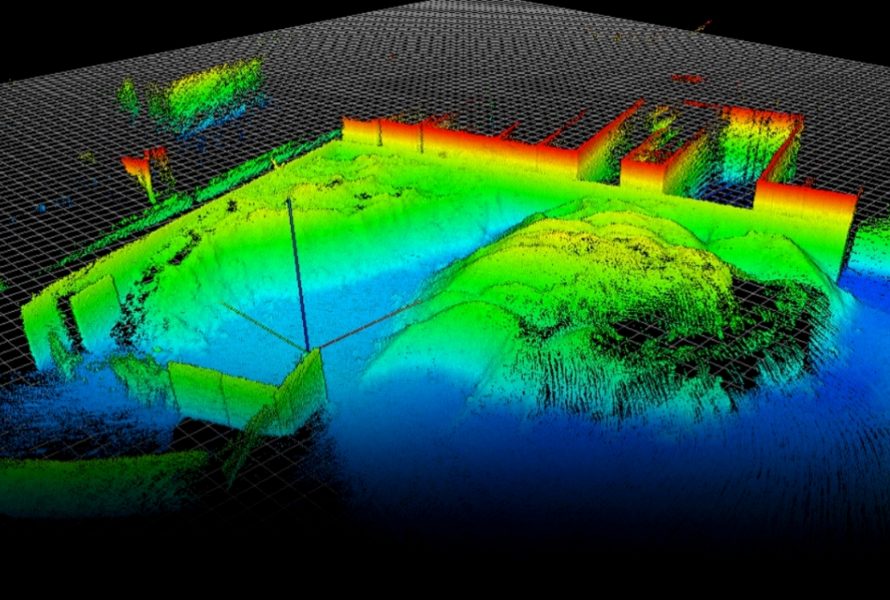

An inspector tested Flyability's new software Inspector 3.0 during a challenging hydrogen reformer inspection and found that it helped them easily return to the location of defects. Read the case study.

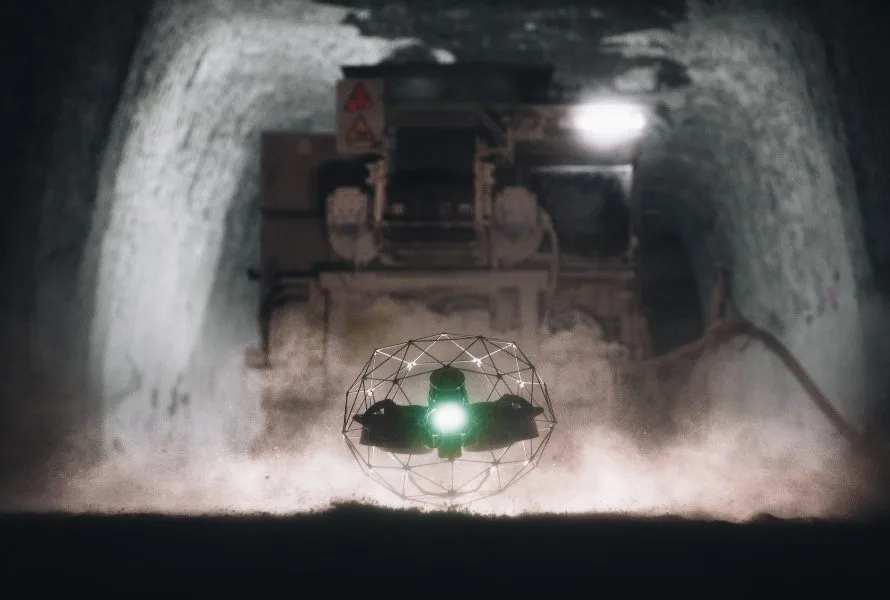

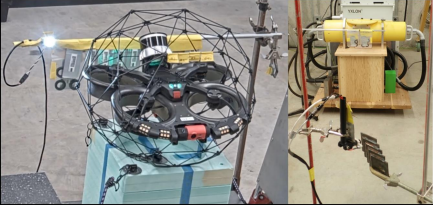

ELIOS 2 TESTED AT FRENCH FERTILIZER PLANT, PROVIDES IMAGES SO CLEAR INSPECTOR FEELS LIKE HE’S STANDING THERE

Personnel at a fertilizer plant owned by Yara tested the Elios 2 to see if it could help speed up their inside inspections and found that the drone provided crystal clear images of hard-to-reach places. Read the case study.